Top 25 Companies in Hvof Tungsten Carbide Coating Market in the World in 2025: Market Research Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

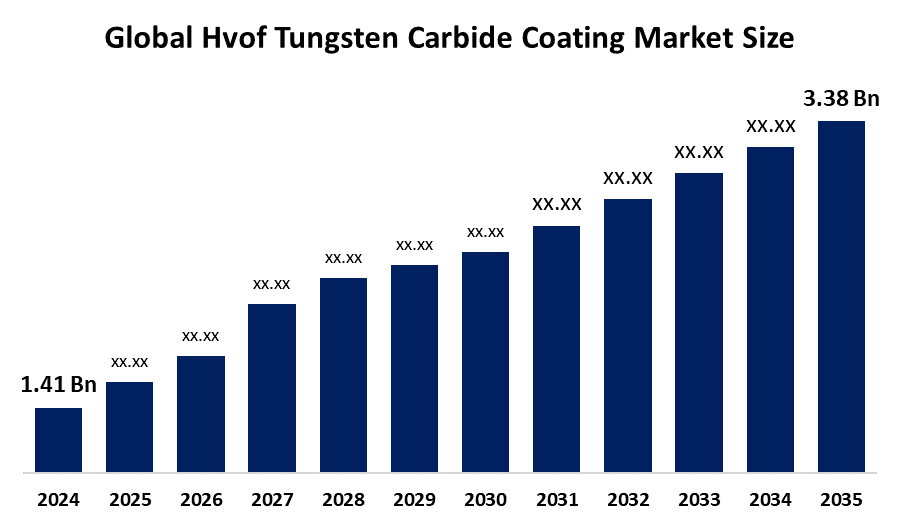

According to a research report published by Spherical Insights & Consulting, The Global Hvof Tungsten Carbide Coating Market Size is projected to Grow from USD 1.41 Billion in 2024 to USD 3.38 Billion by 2035, at a CAGR of 8.27 % during the forecast period 2025–2035. The HVOF Tungsten Carbide Coating market offers future opportunities in aerospace, automotive, oil & gas, and industrial machinery, driven by demand for wear-resistant, corrosion-resistant, high-performance protective coatings.

Introduction

The Market Size for HVOF (High-Velocity Oxy-Fuel) Tungsten Carbide Coatings is rapidly expanding as a result of their excellent properties of wear, corrosion, and heat resistance. HVOF Tungsten Carbide Coating is applied widely in the aerospace, automotive, oil & gas, and industrial machinery sectors to enhance the durability and performance of components in extreme environment applications. HVOF (High-Velocity Oxy-Fuel) Tungsten Carbide Coating technology allows for the application of quality coatings with precision that enhances equipment life, low maintenance costs, and operational efficiency. Factors that are driving growth in the market include industrialization, technology advancement, and the demand for coatings that provide protection in extreme environments. Furthermore, the emphasis on sustainable manufacturing and high-performance materials provides the basis for greater adoption across several industries and long-term market growth.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Hvof Tungsten Carbide Coating market.

Hvof Tungsten Carbide Coating Market Size & Statistics

- The Market Size for Hvof Tungsten Carbide Coating Was Estimated to be Worth USD 1.41 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 8.27 % Between 2025 and 2035.

- The Global Hvof Tungsten Carbide Coating Market is Anticipated to Reach USD 3.38 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Hvof Tungsten Carbide Coating market.

- Asia Pacific is expected to grow the fastest during the forecast period in the Hvof Tungsten Carbide Coating market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the Hvof Tungsten Carbide Coating market. The growth of the market is attributed to rapid industrialization, significant infrastructure investments, and sell a support from the automotive, aerospace, and heavy machinery industries in countries such as China, India, and Southeast Asia. The provision of manufacturing capabilities in the region and the demand for long-lasting, high-performance coatings, which are needed to prolong the life of equipment, have exacerbated this growth potential.

North America is expected to generate the highest demand during the forecast period in the Hvof Tungsten Carbide Coating market. The leadership of this region can be credited to its manufacturing strengths, especially in aerospace, automotive, and energy industries, where there is a high market demand for tough, high-performance coatings. In addition, the focal point of North America is its emphasis on research and development, as well as its performance standards set for industry, that further enhance the market of HVOF coatings. The existence of leading coating service suppliers and end-users, also makes North America dominant in the market.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Hvof Tungsten Carbide Coating market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 5 Trends in Hvof Tungsten Carbide Coating Market

1. Rising Demand for Wear-Resistant Coatings

HVOF tungsten carbide coatings are increasingly adopted for their exceptional wear resistance in industries such as aerospace, automotive, oil & gas, and heavy machinery. The coatings enhance component durability, reduce maintenance costs, and extend service life under extreme operating conditions. As industries face higher performance and reliability standards, the demand for wear-resistant coatings is accelerating. This trend is particularly prominent in sectors dealing with abrasive environments, high-speed machinery, and critical parts, highlighting HVOF coatings as a cost-effective solution for minimizing downtime, improving efficiency, and ensuring long-term operational reliability.

2. Growth in Aerospace and Automotive Applications

Aerospace and automotive sectors are major drivers for HVOF tungsten carbide coatings due to their need for lightweight, durable, and high-performance components. In aerospace, HVOF coatings protect turbine blades, landing gear, and engine parts against wear, corrosion, and high temperatures. In automotive, they are used in engine components, pistons, and fuel injection systems to improve efficiency and longevity. The shift toward electric vehicles, high-performance engines, and sustainable transportation technologies further boosts demand. This trend reflects the coating’s role in enhancing performance, reducing maintenance, and meeting stringent industry standards for safety, efficiency, and reliability.

3. Expansion in Oil & Gas and Industrial Machinery

The oil & gas and industrial machinery sectors are increasingly relying on HVOF tungsten carbide coatings to protect equipment operating in harsh environments. These coatings resist erosion, corrosion, and wear caused by high pressures, abrasive fluids, and extreme temperatures. Industries such as mining, drilling, and heavy manufacturing are adopting HVOF technology to reduce operational costs and extend equipment lifespan. Rising global energy demand and industrialization are driving this adoption. This trend emphasizes the importance of protective coatings in maintaining productivity and minimizing unplanned downtime, positioning HVOF coatings as an essential solution for industrial reliability and efficiency.

4. Technological Advancements in Coating Processes

Advancements in HVOF coating technology are enabling more precise, uniform, and high-performance coatings. Innovations such as automated spray systems, optimized fuel-to-oxygen ratios, and improved powder materials enhance coating adhesion, density, and wear resistance. Hybrid techniques combining HVOF with other thermal spray methods are also emerging to provide multifunctional properties like corrosion protection and thermal insulation. These technological developments are reducing defects, improving efficiency, and lowering production costs. The trend reflects the industry’s focus on continuous improvement, enabling manufacturers to meet increasingly stringent performance requirements and expand the use of HVOF coatings across new industrial applications.

5. Sustainability and Cost Efficiency Focus

There is a growing emphasis on sustainability and cost-effective solutions in the HVOF tungsten carbide coating market. Industries are adopting coatings that reduce maintenance frequency, extend equipment life, and lower material waste, aligning with environmental and economic goals. Additionally, energy-efficient HVOF processes and eco-friendly materials are being developed to minimize emissions and reduce the environmental impact of industrial operations. This trend highlights the convergence of performance and sustainability, as companies seek to optimize operational efficiency while adhering to environmental regulations. HVOF coatings thus provide a long-term, cost-efficient, and environmentally responsible solution across multiple sectors.

Top 20 Companies Leading the Hvof Tungsten Carbide Coating Market

- Praxair Surface Technologies

- Oerlikon Metco

- H.C. Starck Surface Technology and Ceramic Powders GmbH

- Kennametal Stellite

- Saint-Gobain Coating Solutions

- Carpenter Technology Corporation

- ASB Industries, Inc.

- Flame Spray Technologies

- Fujimi Incorporated

- Plasma Powders & Systems, Inc.

- Bodycote plc

- Curtiss-Wright Surface Technologies

- TST Coatings, Inc.

- Thermal Spray Technologies, Inc.

- APS Materials, Inc.

- American Roller Company, LLC

- IMR Test Labs

- Metallisation Ltd.

- Supersonic Spray Technologies, Inc.

- Surface Technology, Inc.

1. Praxair Surface Technologies

Headquarters: Indianapolis, Indiana, USA

Praxair Surface Technologies, now operating as Linde Advanced Material Technologies Inc., is a global leader in surface engineering. Specializing in high-performance coatings, the company offers solutions that enhance the durability and efficiency of components in industries such as aerospace, automotive, and energy. With a strong focus on innovation, Praxair provides advanced thermal spray coatings, including HVOF tungsten carbide coatings, to meet the demanding requirements of modern manufacturing. Their expertise in materials science and coating technologies positions them as a trusted partner for industries seeking to improve performance and extend the lifespan of critical components.

2. Oerlikon Metco

Headquarters: Pfäffikon, Switzerland

Oerlikon Metco is a global provider of surface solutions, specializing in thermal spray coatings, including HVOF tungsten carbide coatings. Serving industries such as aerospace, automotive, and energy, Oerlikon Metco offers a comprehensive range of coating services aimed at improving component performance and longevity. Their advanced technologies and commitment to innovation enable them to deliver high-quality, customized solutions that meet the specific needs of their customers. With a strong global presence, Oerlikon Metco continues to lead in the field of surface engineering.

3. H.C. Starck Surface Technology & Ceramic Powders GmbH

Headquarters: Munich, Germany

H.C. Starck Surface Technology & Ceramic Powders GmbH, a subsidiary of Mitsubishi Materials Corporation, specializes in the production of high-performance powders, including tungsten carbide, for various applications. Their products are integral to the manufacturing of HVOF coatings, providing enhanced wear resistance and durability to components in industries such as aerospace, automotive, and industrial machinery. With a legacy of over 100 years in materials science, H.C. Starck is renowned for its commitment to quality and innovation in the field of ceramic powders and surface technology.

4. Kennametal Stellite

Headquarters: Goshen, Indiana, USA

Kennametal Stellite is a division of Kennametal Inc., focusing on the development and production of wear-resistant materials, including Stellite alloys and HVOF coatings. Their products are widely used in industries such as aerospace, energy, and heavy manufacturing to protect components from extreme wear, corrosion, and high temperatures. Kennametal Stellite's commitment to innovation and quality ensures that their coatings provide superior performance and reliability, meeting the stringent demands of modern industrial applications.

5. Saint-Gobain Coating Solutions

Headquarters: Avignon, France

Saint-Gobain Coating Solutions, a division of the global materials company Saint-Gobain, specializes in the development and production of advanced coating materials, including thermal spray powders and rods. Their products are used in a variety of applications, such as HVOF coatings, to enhance the performance and longevity of components in industries like aerospace, automotive, and energy. With a focus on innovation and sustainability, Saint-Gobain Coating Solutions continues to lead in the field of surface engineering, providing high-quality solutions that meet the evolving needs of their customers.

Are you ready to discover more about the Hvof Tungsten Carbide Coating market?

The report provides an in-depth analysis of the leading companies operating in the global Hvof Tungsten Carbide Coating market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Praxair Surface Technologies.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- Oerlikon Metco

- H.C. Starck Surface Technology and Ceramic Powders GmbH

- Kennametal Stellite

- Saint-Gobain Coating Solutions

- Carpenter Technology Corporation

- ASB Industries, Inc.

- Flame Spray Technologies

- Fujimi Incorporated

- Plasma Powders & Systems, Inc.

Conclusion

The HVOF Tungsten Carbide Coating Market Size is experiencing strong growth, driven by increasing demand for wear-resistant, corrosion-resistant, and high-performance protective coatings across aerospace, automotive, oil & gas, and industrial machinery sectors. Technological advancements, sustainability initiatives, and the adoption of precision coating processes are shaping market dynamics, while North America leads in overall demand and Asia-Pacific emerges as the fastest-growing region. Key trends such as enhanced aerospace and automotive applications, expansion in heavy industry, and focus on cost efficiency highlight the market’s evolving potential. Leading global players continue to innovate, providing strategic opportunities for manufacturers and end-users worldwide.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?