Top 20 Companies in Plastic Film Slitter Rewinder Market Worldwide 2025: Market Research Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

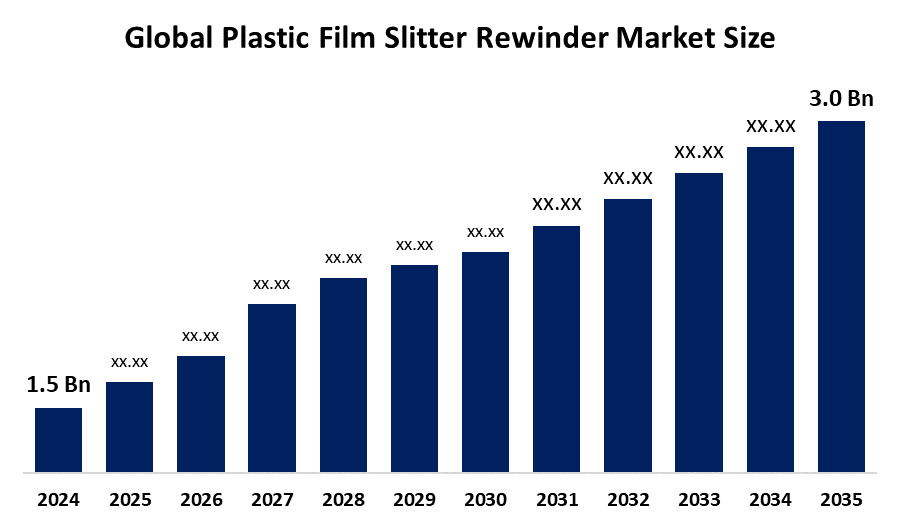

According to a research report published by Spherical Insights & Consulting, The Global Plastic Film Slitter Rewinder Market Size is projected to Grow from USD 1.5 Billion in 2024 to USD 3.0 Billion by 2035, at a CAGR of 6.5% during the forecast period 2025–2035. This growth is driven by the growing need for high-quality packaging solutions in a variety of industries, which is being driven by both consumer preference for packaged goods and technological advancements.

Introduction

The term Global Plastic Film Slitter Rewinder Market Size refers to the segment of the industry that consists of producing and selling machines capable of slitting and rewinding plastic films with accuracy and efficiency. Slitter rewinders serve a vital role in the conversion of large rolls of plastic film into smaller formats for more efficient use, all while allowing for the material to still be intact and in alignment. Slitter rewinders are widely used in the industries of packaging, printing, and industrial processing to help increase speed, minimize losses, and improve efficiency. Additionally, the market for plastic film slitter rewinders offers a wealth of chances for expansion and creativity. The creation of cutting-edge technologies and automation solutions presents one of the main opportunities. Slitting and rewinding machinery that incorporates Industry 4.0 and IoT technologies provides improved control over production processes, predictive maintenance, and real-time data monitoring. Manufacturers can gain a competitive edge from these developments by greatly increasing operational efficiency, decreasing downtime, and lowering operating costs. The increasing demand for high-quality and effective film processing equipment is likely to benefit businesses that make research and development investments to produce creative and automated solutions.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Plastic Film Slitter Rewinder Market.

Plastic Film Slitter Rewinder Market Size & Statistics

- The Market Size for Plastic Film Slitter Rewinder Was Estimated to be Worth USD 1.5 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 6.5% Between 2025 and 2035.

- The Global Plastic Film Slitter Rewinder Market Size is Anticipated to Reach USD 3.0 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Plastic Film Slitter Rewinder Market.

- North America is expected to grow the fastest during the forecast period in the Plastic Film Slitter Rewinder Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the plastic film slitter rewinder market. Growing disposable income, technological advancements, and the growing need for flexible packaging solutions are the main drivers of the Asia Pacific market's expansion.

North America is expected to generate the highest demand during the forecast period in the plastic film slitter rewinder market. This is driven by developments in technology and the expanding use of flexible packaging options. At a consistent CAGR of 4.5%, the market size in the region is anticipated to reach approximately USD 800 million by 2032. High-quality film processing equipment is in high demand in North America due to the presence of significant players in the consumer goods and packaging industries as well as the growing emphasis on environmentally friendly packaging.

Top 10 Plastic Film Slitter Rewinder Trends

1.Smart controls and automation

2.Fast and Broad Web Access

3.Waste Reduction and Sustainability

4.Designs that are Adaptable and Modular

5.Increased Demand for Flexible Packaging

6.Industrial Integration 4.0.

7.Space Efficiency and Small Footprint

8.Improved ergonomics and safety

9.Growth of Regional Manufacturing

10.Compatibility of Multiple Materials

1. Smart controls and automation

To increase accuracy, decrease downtime, and boost operational efficiency, manufacturers are incorporating sophisticated automation and intelligent control systems into slitter rewinder machines. In order to facilitate smooth production and real-time diagnostics, features like auto-tension control, edge guiding, and programmable logic controllers (PLCs) are becoming commonplace.

2. Fast and Broad Web Access

High-speed and wide-web slitter rewinders are becoming more and more in demand, particularly for industrial film and flexible packaging applications. These devices help converters meet strict delivery deadlines and increase production without sacrificing quality by supporting higher throughput and larger rolls.

3. Waste Reduction and Sustainability

Innovations aimed at reducing material waste during slitting and rewinding are being driven by environmental concerns. In packaging and conversion operations, businesses are lowering scrap rates and achieving sustainability goals with the aid of improved blade systems, precise tension control, and recyclable film handling.

4. Designs that are Adaptable and Modular

To accommodate a variety of application requirements, manufacturers are working on modular slitter rewinder systems that can be made with add-ons, turret rewinders, laser perforators, and inspection units. This will enhance the converters' ability to respond quickly to changes in the marketplace and specifications for product configurations.

5. Increased Demand for Flexible Packaging

Demand for slitter rewinders that can handle a variety of plastic films is being driven by the growth in flexible packaging in the food, pharmaceutical, and personal care industries. Machines with improved tension control and web handling capabilities are being tuned for materials like BOPP, PET, and PE.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the plastic film slitter rewinder market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Plastic Film Slitter Rewinder Market

1.Atlas Converting Equipment Ltd

2.Kampf Schneid- und Wickeltechnik GmbH & Co. KG

3.GOEBEL IMS

4.Euromac S.r.l.

5.Parkinson Technologies Inc.

6.ASHE Converting Equipment

7.Pasquato Cutting Machines

8.Laem System S.r.l.

9.Jennerjahn Machine, Inc.

10.Elite Cameron Ltd

11.Deacro Industries Ltd.

12.Nishimura Mfg. Co., Ltd.

13.Catbridge Machinery

14.HCI Converting Equipment Co., Ltd.

15.SOMA Engineering

16.Kataoka Machine Co., Ltd.

17.Others

1. Atlas Converting Equipment Ltd

Headquarters - Kempston, Bedford, England, United Kingdom

Atlas Converting Equipment Ltd. is a well-known manufacturer with a focus on designing and building primary and secondary slitter rewinder systems for flexible materials like paper, plastic films, label stock, and laminates. The company has a long history of precision engineering and provides high-performance solutions that support advanced converting operations, increase productivity, and decrease downtime. Advanced platforms like the Titan and Atlas CW series, which combine intelligent controls, modular configurations, and effective web handling systems, are part of its product line.

2. Kampf Schneid- und Wickeltechnik GmbH & Co. KG

Headquarters - Wiehl, North Rhine-Westphalia, Germany

A leader in slitting and winding technologies worldwide, Kampf Schneid-und Wickeltechnik GmbH & Co. KG provides cutting-edge equipment for processing flexible materials like battery separator films, laminates, plastic films, and aluminum foils. With more than a century of experience, the company provides high-performance solutions for energy storage, electronics, and packaging applications. Kampf offers primary and secondary slitters, non-stop winders, and specialized systems for the manufacturing of lithium-ion batteries.

3. GOEBEL IMS

Headquarters - Darmstadt, Hesse, Germany.

A prominent producer of slitter rewinder systems for the high-precision processing of paper, plastic films, laminates, and specialty materials is GOEBEL IMS. The business has been providing cutting-edge solutions for packaging, industrial, and battery separator film applications for more than 170 years. Modular design, automation, and high-speed capabilities catered to demanding production environments are all demonstrated by its INTERSLIT series.

4. Euromac S.r.l.

Headquarters - Marano Vicentino, Veneto, Italy

One of the top producers of slitter rewinder machines worldwide, Euromac S.r.l. focuses on high-precision machinery for processing aluminum foil, paper, plastic films, and laminates. The business provides cutting-edge solutions designed for flexible packaging and industrial applications thanks to decades of engineering experience. Modern CAD systems are used in the development of Euromac's machines, which also feature proprietary electronic controls for reliable performance, modular adaptability, and simple integration with automated production lines.

5. Parkinson Technologies Inc.

Headquarters - Woonsocket, Rhode Island, United States.

An established supplier of cutting-edge web processing systems, Parkinson Technologies Inc. provides orientation lines, extrusion tools, and slitter rewinders specifically designed for plastic film and sheet applications. The company provides high-performance slitting and rewinding solutions under the Dusenbery brand that transform master rolls into precise, finished formats for the packaging, industrial, and specialty markets. Its systems are designed to improve polymer film mechanical and optical qualities, facilitate processing of high recycled content, and blend in perfectly with continuous production lines.

Are you ready to discover more about the plastic film slitter rewinder market?

The report provides an in-depth analysis of the leading companies operating in the global plastic film slitter rewinder market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

1.Atlas Converting Equipment Ltd

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

2.Kampf Schneid- und Wickeltechnik GmbH & Co. KG

3.GOEBEL IMS

4.Euromac S.r.l.

5.Parkinson Technologies Inc.

6.ASHE Converting Equipment

7.Pasquato Cutting Machines

8.Laem System S.r.l.

9.Jennerjahn Machine, Inc.

10.Elite Cameron Ltd

11.Deacro Industries Ltd.

12.Nishimura Mfg. Co., Ltd.

13.Catbridge Machinery

14.HCI Converting Equipment Co., Ltd.

15.SOMA Engineering

16.Kataoka Machine Co., Ltd.

17.Others

Conclusion

The Worldwide Plastic Film Slitter Rewinder Market Size is expected to see stable growth, due to the rise in demand for flexible packaging, combined with enhanced automation or smart manufacturing and the concept of Industry 4.0. The global shift to modular equipment designs and emerging sustainable technologies will transform the capabilities of the equipment, as well as operational efficiency. The Asia Pacific region is the foremost region responsible for production and uptake and North America demonstrates a strong demand for high-quality, sustainable products. Leading OEMs are investing in R&D to provide their customers with high-precision equipment that is agile and versatile. As the packaging quality standard continues to increase, slitter rewinder technologies will continue to be critical to scale up precision film processing.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?