Top 20 Companies in Lithium Battery Diaphragm Market Worldwide 2025: Market Research Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

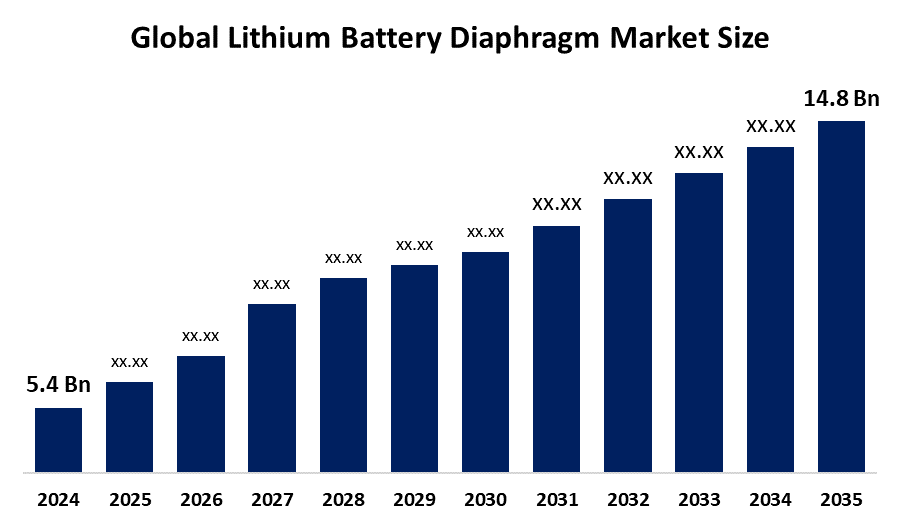

According to a research report published by Spherical Insights & Consulting, The Global Lithium Battery Diaphragm Market Size is projected to Grow from USD 5.4 Billion in 2024 to USD 14.8 Billion by 2035, at a CAGR of 9.6% during the forecast period 2025–2035. The market is mostly driven by the growing need for high-performance lithium-ion batteries in a variety of applications, including energy storage systems, electric cars, and consumer electronics. The market is expanding due to factors like improved battery technologies, stricter environmental laws, and increased investments in renewable energy sources.

Introduction

The Global Lithium Battery Diaphragm Market Size refers to the industry focused on producing and supplying separator membranes for use in lithium-ion batteries is known as the "global lithium battery diaphragm market." In order to ensure safe and effective energy transfer during charge and discharge cycles, these diaphragms are essential parts that physically separate the anode and cathode while permitting ionic conductivity. Lithium battery diaphragms, which are distinguished by their thin, porous structure and thermal stability, are essential for improving battery longevity, performance, and safety. Additionally, the market for lithium battery diaphragms has a big chance as sustainability gains more attention. Environmentally friendly diaphragms, like those composed of recyclable or biodegradable materials, are being developed by manufacturers. In addition to meeting the increasing environmental concerns, this move toward sustainable diaphragm materials offers new growth prospects in markets with stricter regulations. Furthermore, there will be more opportunities for diaphragms that support higher energy density, longer battery life, and faster charging as lithium-ion battery technology develops.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Lithium Battery Diaphragm Market.

Lithium Battery Diaphragm Market Size & Statistics

- The Market Size for Lithium Battery Diaphragm Was Estimated to be Worth USD 5.4 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 9.6% Between 2025 and 2035.

- The Global Lithium Battery Diaphragm Market Size is Anticipated to Reach USD 14.8 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Lithium Battery Diaphragm Market.

- North America is expected to grow the fastest during the forecast period in the Lithium Battery Diaphragm Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the lithium battery diaphragm market. The growing demand for electric vehicles and improvements in battery technologies are the main drivers of the region's growth. The market expansion is further supported by the existence of major North American automakers and tech firms. Furthermore, the need for high-performance lithium-ion batteries with cutting-edge dry diaphragms is being driven by the growing emphasis on energy storage and renewable energy sources.

Asia Pacific is expected to generate the highest demand during the forecast period in the lithium battery diaphragm market. Divided by the growing popularity of electric vehicles and the existence of major battery manufacturers. With large investments in EV infrastructure and pro-EV government policies, nations like China, Japan, and South Korea are leading the way in the electric vehicle revolution. The fast expansion of the consumer electronics sector, which fuels the need for high-performance lithium-ion batteries, is another factor contributing to the region's dominance.

Top 10 Lithium Battery Diaphragm Trends

1.Separators with nanocoatings

2.Optimization of Wet versus Dry Processes

3.Higher-Porosity, Thinner Films

4.Structures with Two or More Layers

5.Improved Safety Functions

6.Sustainable Resources

7.Adaptation to Cell Formats

8.Solid-state battery integration

9.Quality Control Powered by AI

10.Regional Growth in Manufacturing

1. Separators with nanocoatings

Advanced nanocoatings, like ceramic or alumina layers, are being applied to diaphragms to improve their mechanical strength and thermal stability. These coatings enhance safety, particularly in batteries for electric vehicles, and lessen shrinkage at high temperatures.

2. Optimization of Wet versus Dry Processes

To balance cost, performance, and scalability, manufacturers are improving both wet and dry production techniques. Dry processes are becoming more popular due to their energy and environmental advantages, while wet processes provide superior homogeneity and porosity.

3. Higher-Porosity, Thinner Films

The development of ultra-thin diaphragms with controlled porosity is being driven by the need for higher energy density. For high-capacity and fast-charging battery applications, these enable quicker ion transfer while preserving mechanical integrity.

4. Structures with Two or More Layers

The ability of multi-layer separators to integrate various material qualities-like strength, heat resistance, and electrolyte compatibility-into a single composite structure is making them more and more popular. This enhances battery performance overall.

5. Improved Safety Functions

To avoid short circuits and thermal runaway, diaphragms are being designed with shutdown features that activate when they experience thermal stress. Because safety is of the utmost importance, this trend is particularly significant for EVs and grid storage systems.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the lithium battery diaphragm market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Lithium Battery Diaphragm Market

1.Asahi Kasei

2.Toray Industries

3.SK IE Technology

4.Entek International

5.W-SCOPE Corporation

6.UBE Corporation

7.Sumitomo Chemical

8.Celgard LLC

9.Freudenberg Performance Materials

10.Mitsubishi Chemical Group

11.Shenzhen Senior Technology Material Co., Ltd.

12.Sinoma Science & Technology Co., Ltd.

13.SEMCORP Group

14.Suzhou GreenPower New Energy Materials Co., Ltd.

15.Shanghai Energy New Materials Technology Co., Ltd.

16.LG Chem

17.Others

1. Asahi Kasei

Headquarters - Chiyoda-ku, Tokyo, Japan.

A manufacturer with a focus on chemical products is Asahi Kasei Corp (Asahi Kasei). Styrene monomer, acrylonitrile polyethylene, polystyrene, synthetic rubber, lithium-ion battery separators, hollow fiber filtration membranes, ion exchange membranes, and pharmaceuticals are among the many products that the company produces. Additionally, Asahi Kasei provides services for companies that are Contract Development and Manufacturing Organizations (CDMO) and Contract Research Organizations (CRO). Duranol, Sepacell, Polydurex, Ceolus, Aciplex, and Hipore are just a few of the brands that the company sells its goods under. Its products are used in a wide range of industries, including construction, electronics, healthcare, and chemicals and fibers.

2. Toray Industries

Headquarters - Tokyo, Japan.

A supplier of cutting-edge materials is Toray Industries Inc. (Toray). The company's product line consists of fibers, fashion clothing, plastics, chemicals, composite materials, life sciences products, pharmaceuticals, medical devices, and optical items. Additionally, it offers polyester, polyethylene, polypropylene, carbon fibers, carbon fiber composite materials, and water treatment membranes. Its goods are utilized in the construction, water treatment, medical, automotive, industrial materials, and clothing industries. It also offers services linked to research, analysis, and physical evaluation. Toray also offers materials for building, civil engineering, and residential applications, as well as comprehensive engineering, condominiums, industrial machinery and equipment, IT-related equipment, and water treatment membranes and related equipment.

3. SK IE Technology

Headquarters - South Korea

SK IE Technology is a world leader in the production of lithium-ion battery separators, with a focus on high-performance ceramic-coated and film-based separators for IT devices and electric cars. The business, a division of SK Innovation, uses cutting-edge material science and exclusive coating technologies to improve battery thermal stability, energy density, and safety. Its product line supports next-generation energy storage systems, emphasizing scalable solutions and environmentally friendly production.

4. Entek International

Headquarters - Lebanon, Oregon, United States

Entek International is a specialist in battery separator technologies, providing cutting-edge porous polymer membranes for lead-acid and lithium-ion batteries to international markets. The company focuses on high-performance materials that improve battery safety, efficiency, and longevity in its engineered solutions for energy storage systems, electric vehicles, and industrial applications. Entek provides extrusion equipment and technical services in addition to producing separators, enabling turnkey manufacturing capabilities for the plastics and battery industries.

5. W-SCOPE Corporation

Headquarters – Japan

W-SCOPE Corporation is a specialist producer of lithium-ion battery separators, providing cutting-edge membrane film technologies that improve the energy density, safety, and efficiency of batteries. The business specializes in high-performance polyethylene-based separators for energy storage systems, consumer electronics, and electric cars. W-SCOPE produces goods that satisfy exacting mechanical and thermal specifications by using patented coating and extrusion techniques.

Are you ready to discover more about the lithium battery diaphragm market?

The report provides an in-depth analysis of the leading companies operating in the global lithium battery diaphragm market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

1.Asahi Kasei

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

2.Toray Industries

3.SK IE Technology

4.Entek International

5.W-SCOPE Corporation

6.UBE Corporation

7.Sumitomo Chemical

8.Celgard LLC

9.Freudenberg Performance Materials

10.Mitsubishi Chemical Group

11.Shenzhen Senior Technology Material Co., Ltd.

12.Sinoma Science & Technology Co., Ltd.

13.SEMCORP Group

14.Suzhou GreenPower New Energy Materials Co., Ltd.

15.Shanghai Energy New Materials Technology Co., Ltd.

16.LG Chem

17.Others

Conclusion

The Lithium Battery Separator Market Size worldwide is poised to experience considerable growth, and this growth is driven by increasing demand in Electric Vehicles, energy storage and consumer electronics. Separator architectural advancements, such as the use of nanocoating technology, multilayer structures, and toll tariffs to add polymer or ceramic coatings, are acting to improve the safety, efficiency, and energy density of batteries. Sustainability measures and government regulations are encouraging companies to make designs with more environmentally friendly separators. The Asia Pacific region has the highest demand due to the concentration of batteries manufactured in this region. North America is expected to grow the fastest due to innovation in communications technology and alternative clean energy investments. The market continues to provide opportunities for manufacturers and stakeholders as trends evolve and create new areas for innovation.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?