Top 20 Companies in Continuous Tubular Reactor (CTR) Market: Statistics Report Till 2035

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

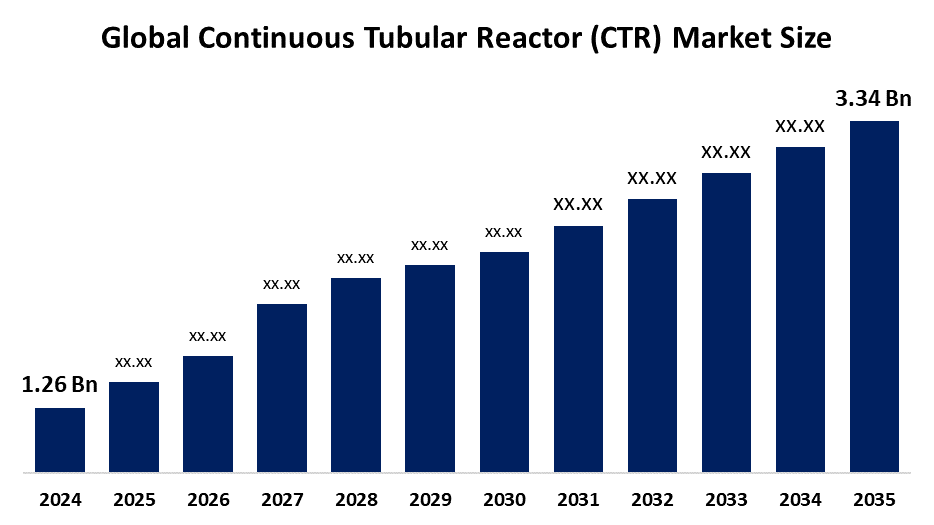

According to a research report published by Spherical Insights & Consulting, The Global Continuous Tubular Reactor (CTR) Market Size is projected to Grow from USD 1.26 Billion in 2024 to USD 3.34 Billion by 2035, at a CAGR of 9.27% during the forecast period 2025–2035. This notable expansion is due to the rising need for effective and scalable chemical processing machinery in multiple sectors. Elements like progress in chemical engineering, growth in pharmaceutical research, and higher adoption rates in petrochemical sectors are propelling market expansion. The continuous tubular reactor is becoming increasingly popular because it offers uniform, high-quality production results. A key growth factor for the CTR market is the enhanced efficiency it provides in comparison to conventional batch reactors.

Introduction

In industrial chemical processes where reactants flow continuously through a cylindrical tube or pipe, a Continuous Tubular Reactor (CTR), also called a Plug Flow Reactor (PFR), is a type of chemical reactor that is frequently utilised. The fluid flows in the axial direction without axial mixing but with full radial mixing as a sequence of distinct plugs, each with a uniform composition. This makes it possible for the reactor's length to have a concentration gradient. A Continuous Tubular Reactor (CTR) is a type of reactor that is intended to provide precise control and efficiency for continuous chemical production processes by allowing reactants to flow continuously through a tubular system. The chemical reaction occurs as the fluid moves down the tube. Continuous tubular reactors facilitate ongoing processing, greatly minimising downtime and improving resource efficiency. This effectiveness is especially vital in sectors like pharmaceuticals and chemicals, where slight enhancements in processing efficiency can lead to significant cost reductions and higher profitability. This corresponds with the worldwide movement for green chemistry and sustainable practices in industrial operations. Moreover, the capacity to finely regulate reaction variables in continuous tubular reactors leads to improved product quality and reduced by-products, further fueling their use in different sectors.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Continuous Tubular Reactor (CTR) Market.

Continuous Tubular Reactor (CTR) Market Size & Statistics

- The Market Size for Continuous Tubular Reactor (CTR) Was Estimated to be worth USD 1.26 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 9.27% between 2025 and 2035.

- The Global Continuous Tubular Reactor (CTR) Market Size is anticipated to reach USD 3.34 Billion by 2035.

- Asia Pacific is estimated to generate the highest demand during the forecast period in the continuous tubular reactor (CTR) market.

- North America is anticipated to grow the fastest during the forecast period in the continuous tubular reactor (CTR) market.

Regional growth and demand

North America is projected to grow at the fastest CAGR over the forecast period in the continuous tubular reactor (CTR) market. North America serves as another important area for the continuous tubular reactor market is fueled by the existence of well-established chemical and pharmaceutical sectors and continual technological progress. The United States plays a key role in the expansion of the market in North America, highlighting considerable funding in research and development, along with a strong emphasis on innovation and process improvement. The need for continuous tubular reactors in North America is fueled by the requirement for efficient and scalable production techniques, especially within the pharmaceutical and chemical sectors. The emphasis on sustainability and eco-friendly production techniques in the region is also anticipated to promote the use of continuous tubular reactors.

Asia Pacific is expected to grow at the highest share during the forecast period in the continuous tubular reactor (CTR) market. The market for continuous tubular reactors is expected to grow significantly in a number of regions due to factors like industrialisation, advancements in technology, and a greater focus on environmentally friendly production methods. The Asia Pacific area is anticipated to experience the greatest growth rate throughout the forecast period, fueled by swift industrialisation, substantial investments in the chemical and pharmaceutical sectors, and a growing emphasis on sustainable production practices in nations such as China, India, and Japan. The increasing population in the region and heightened demand for premium products are predicted to propel the use of continuous tubular reactors across multiple industries.

Top 10 trends in the Continuous Tubular Reactor (CTR) Market

- Surge in Pharmaceutical Applications

- Green Chemistry & Sustainability Push

- Advanced Materials Adoption

- Rise of Multi-Phase Reactor Designs

- Digitalization & Smart Monitoring

- Expansion in Food & Beverage Processing

- Modular & Scalable Reactor Systems

- Customisation for Speciality Chemicals

- Shift Toward Continuous Manufacturing

- Growth in Asia-Pacific & Latin America

1. Surge in Pharmaceutical Applications

Because of their accuracy, scalability, and capacity to maintain constant reaction conditions, CTRs are being utilised more and more in drug synthesis and formulation.

2. Green Chemistry & Sustainability Push

CTRs provide less waste production and energy-efficient processing, which is in line with international sustainability objectives and legal requirements.

3. Advanced Materials Adoption

Although glass and stainless steel continue to be the most common materials, advances in composites and corrosion-resistant alloys are increasing reactor capacity.

4. Rise of Multi-Phase Reactor Designs

Particularly in the petrochemical and speciality chemical industries, multi-phase CTRs are becoming more popular for complicated reactions involving gas-liquid or liquid-solid phases.

5. Digitalisation & Smart Monitoring

Process optimisation and predictive maintenance are being improved through the integration of IoT sensors, AI-based control systems, and real-time analytics.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the continuous tubular reactor (CTR) market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the Continuous Tubular Reactor (CTR) Market

- BASF SE

- Dow Chemical Company

- DuPont de Nemours, Inc.

- Evonik Industries AG

- LyondellBasell Industries N.V.

- SABIC

- Mitsubishi Chemical Corporation

- LG Chem Ltd.

- ExxonMobil Chemical Company

- INEOS Group Holdings S.A.

- Akzo Nobel N.V.

- Clariant AG

- Huntsman Corporation

- Eastman Chemical Company

- Celanese Corporation

- Sumitomo Chemical Co., Ltd.

- Toray Industries, Inc.

- Covestro AG

- Arkema S.A.

- Wacker Chemie AG

1. BASF SE

Headquarters: Rhineland Palatinate, Germany

As a major worldwide supplier of process catalysts, adsorbents, and chemical intermediates, the crucial elements that permit the reactions occurring inside the reactors, BASF SE is primarily involved in the Continuous Tubular Reactor (CTR) Market. The operation of these reactors is essential to BASF's operations. The opening of BASF's new Catalyst Development and Solids Processing Centre demonstrates the company's ongoing investment in R&D. This facility focuses on creating and refining catalyst and process technologies that are critical to the chemical industry's green transformation. These technologies include solutions that increase energy demand and lower the carbon footprint of production processes carried out in reactors such as CTRs.

2. Dow Chemical Company

Headquarters: Midland, Michigan, United States

The Dow Chemical Company plays a significant role in the Continuous Tubular Reactor (CTR) Market, mainly as a large end-user and licensor of CTR technology, especially in the polymer and petrochemical industries. Dow ranks among the biggest manufacturers of Low-Density polyethene (LDPE) globally. This kind of polyethene is generally produced through a High-Pressure method that depends significantly on Continuous Tubular Reactors (CTRs). Ethylene polymerisation at high temperatures and extreme pressures (reaching 100,000 psi) is a traditional continuous flow method that is well-suited for tubular reactor setups. Through the licensing of these processes (such as the METEOR Process for EO), Dow directly impacts the global adoption, design, and efficiency of CTRs, offering customers.

3. DuPont de Nemours, Inc

Headquarters: Wilmington, Delaware, United States

DuPont de Nemours, Inc. (DuPont) is a worldwide leader in innovation for technology-driven materials and solutions. Its participation in the Continuous Tubular Reactor (CTR) Market mainly comprises being a key end-user, technology innovator, and manufacturer of high-value speciality chemicals, polymers, and essential purification systems that depend on or effectively operate as continuous flow systems. DuPont's historical heritage and current activities in speciality chemicals and polymers frequently employ extensive continuous polymerisation and synthesis processes. Although particular modern reactor designs are confidential, numerous hallmark products from the company necessitate exact and ongoing management of reaction conditions.

4. Evonik Industries AG

Headquarters: North Rhine-Westphalia, Germany

Evonik Industries AG's engagement in the Continuous Tubular Reactor (CTR) Market is extensive, establishing the firm as a significant end-user of continuous processes and a prominent solution provider (through specialised catalysts, reactor parts, and process expertise). Evonik's approach in the CTR market has two main aspects: enhancing internal efficiency through continuous processes for its varied speciality chemical portfolio and providing specialised materials and expertise (mainly catalysts) that enable the continuous flow processes for its worldwide clients. Evonik is an international speciality chemicals firm concentrated on high-margin, innovative items, typically manufactured in highly efficient, continuous settings.

5. LyondellBasell Industries N.V.

Headquarters: Houston, Texas, USA

One of the biggest producers of chemicals, plastics, and refining in the world, LyondellBasell is also a major licensor of polyolefin technologies. This kind of high-pressure reactor is necessary for the production of some of the key polymers in their portfolio. LYB is important in the continuous tubular reactor (CTR) market. A significant participant in the global chemical and polymer industry, LyondellBasell Industries N.V. (LYB) mainly participates in the continuous tubular reactor (CTR) market through its licensing business for cutting-edge polyolefin technology. LyondellBasell is a significant technology supplier and end-product manufacturer in the Continuous Tubular Reactor market. Its Lupotech T technology is a key component of the world's high-pressure LDPE and EVA production environment.

Are you ready to discover more about the continuous tubular reactor (CTR) market?

The report provides an in-depth analysis of the leading companies operating in the global continuous tubular reactor (CTR) market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- BASF SE

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Dow Chemical Company

- DuPont de Nemours, Inc.

- Evonik Industries AG

- LyondellBasell Industries N.V.

- SABIC

- Mitsubishi Chemical Corporation

- LG Chem Ltd.

- ExxonMobil Chemical Company

- INEOS Group Holdings S.A.

- Akzo Nobel N.V.

- Clariant AG

- Huntsman Corporation

- Eastman Chemical Company

- Celanese Corporation

- Sumitomo Chemical Co., Ltd.

- Toray Industries, Inc.

- Covestro AG

- Arkema S.A.

- Wacker Chemie AG

- Others

Conclusion

The Market Size for Continuous Tubular Reactors (CTR) is rapidly growing, expected to rise from $1.26 billion in 2024 to $3.34 billion by 2035, reflecting a CAGR of 9.27%, fueled by worldwide demand for efficient, scalable, and sustainable chemical processing. The competitive environment of the market is shaped by the Top 20 Companies, which primarily belong to two essential categories: manufacturers/end-users of high-value polymers and chemicals, as well as solution providers/technology licensors. The future of the market will be influenced by crucial trends such as the rise in Pharmaceutical Uses, the necessity for Green Chemistry & Sustainability, and the incorporation of Digitalization & Smart Monitoring. Regional expansion is expected to be driven by the Asia Pacific area, anticipated to produce the highest demand owing to swift industrialization, while North America is forecasted to grow the quickest, supported by cutting-edge chemical and pharmaceutical research and development.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?