Top 15 Companies in Global Titanium Alloys Market (2025–2035): Competitive Analysis and Forecast

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

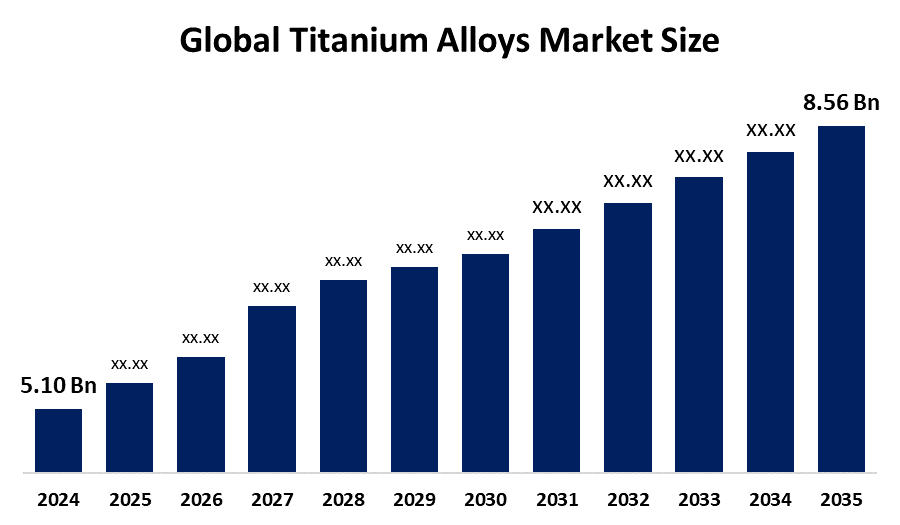

According to a research report published by Spherical Insights & Consulting, The Global Titanium Alloys Market Size is projected to Grow from USD 5.10 Billion in 2024 to USD 8.56 Billion by 2035, at a CAGR of 4.82% during the forecast period 2025–2035. The global titanium alloys market is expanding due to the increasing use of lightweight, high-strength materials in the aerospace and automotive industries, growing demand for corrosion-resistant alloys in medical and industrial applications.

Introduction

The Titanium Alloys Market Size refers to the global industry focused on the production, development, and application of alloys that combine titanium with other metals, such as aluminum, vanadium, and molybdenum, to enhance strength, corrosion resistance, and thermal stability. Titanium alloys are lightweight yet exceptionally durable, making them indispensable across critical industries. They are widely used in aerospace, defense, automotive, energy, and medical sectors, where performance and reliability are paramount. Their biocompatibility makes them suitable for use in joint replacements, dental implants, and surgical equipment, whilst their high strength-to-weight ratio provides efficiency and safety in aviation engines, airframes, and spacecraft. Factors driving market expansion include increased aircraft production, stricter fuel economy regulations in automobile design, an ageing population requiring improved implants, and advancements in alloy design and additive manufacturing. Increased emphasis on sustainability and recycling benefits the sector by lowering its reliance on basic raw resources. Notably, the aircraft Titanium Machining Market is expanding as a specialist segment, stressing precise engineering and innovative production processes to satisfy the demanding demands of aircraft components.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Titanium Alloys Market.

Titanium Alloys Market Size & Statistics

- The Market Size for Titanium Alloys Was Estimated to be worth USD 5.10 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 4.82% between 2025 and 2035.

- The Global Titanium Alloys Market Size is anticipated to reach USD 8.56 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Titanium Alloys Market

- North America is expected to grow the fastest during the forecast period in the Titanium Alloys Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Titanium Alloys market. North America is expected to grow fastest in the titanium alloys market due to robust aerospace and defense investments, rising demand for medical implants, strong R&D in advanced alloys, and expanding recycling initiatives supporting sustainable, high-performance material supply chains.

Asia Pacific is expected to generate the highest demand during the forecast period in the Titanium Alloys market. Asia Pacific is expected to generate the highest demand in the titanium alloys market due to rapid industrialization, expanding aerospace and automotive manufacturing, growing healthcare infrastructure, and increased defense spending in countries like China, India, and Japan.

Top 10 Trends in the Titanium Alloys Market

- Rising Demand in Aerospace and Defense

- Growth in the Medical Industry

- Emergence of Additive Manufacturing

- Increased Use of Renewable Energy

- Sustainability Initiatives and Recycling

- Focus on Cost Reduction and Efficiency

- Automotive Applications

- Development of New Alloy Grades

- Strategic Investment in Production Capacity

- Advancements in Surface Treatments and Coatings

1. Rising Demand in Aerospace and Defense

Titanium alloys, with their excellent strength-to-weight ratio, corrosion resistance, and heat tolerance, are perfect for aviation, spacecraft, and defense equipment. Fleet modernization, increased air travel, and rising military expenditures are creating major demand in the aerospace and defense industries worldwide.

2. Growth in the Medical Industry

Titanium alloys are biocompatible and non-toxic, making them commonly utilized in implants such as joints, dental, spinal, and cardiovascular devices. Aging populations and increased surgical procedures, together with tailored implant technologies, are driving market expansion in the medical and healthcare sectors.

3. Emergence of Additive Manufacturing

Additive manufacturing enables the fabrication of complex, custom-designed titanium alloy components, which are particularly useful in the aerospace, automotive, and medical industries. It eliminates material waste, shortens production cycles, and enables lightweight, high-performance designs that traditional manufacturing cannot deliver.

4. Increased Use of Renewable Energy

Titanium alloys are rapidly being used in renewable energy infrastructure, such as wind turbines, solar panel mounting, and chemical processing equipment. Their strength, endurance, and corrosion resistance make them appropriate for hostile situations, hence promoting growth in sustainable energy initiatives.

5. Sustainability Initiatives and Recycling

Recycling titanium waste from manufacturing and discarded components decreases dependency on raw materials, minimizes carbon emissions, and saves money. Advanced recycling procedures improve scrap quality, assuring an ecologically friendly and economically viable supply for aerospace, medical, and industrial applications.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the titanium alloys market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the Titanium Alloys Market

- ABLTi Corporation

- ADMA Products, Inc.

- Allegheny Technologies

- Altemp Alloys

- AMG

- Arcam

- Arconic Corporation

- ATI Inc.

- Daido Metal Co., Ltd

- Global Titanium

- Haynes International, Inc.

- Hermith GmbH

- Kobe Steel, Ltd

- Korporatsiya VSMPO-AVISMA PAO

- Metalysis

- Nippon Steel Corp

- OSAKA Titanium

- Shanghai LTM industry Co., LTD

- TLS Technik

- Toho Titanium Co Ltd

- United Titanium, Inc.

- Carpenter Technology Corporation

- Timet (Titanium Metals Corporation)

- Baoji Titanium Industry Co., Ltd

- Howmet Aerospace

- Precision Castparts Corp. (PCC)

1. ABLTi Corporation

Headquarters: Shanghai, China

ABLTi Corporation (ABL Titanium), based in Shanghai, China, is a well-known manufacturer of titanium products that serve a wide range of sectors. Its product line comprises titanium tubes, plates, bars, forgings, fasteners, and clad materials, all of which are engineered to fulfill high-performance standards. These goods are frequently utilized in the aerospace, medical, petrochemical, and marine industries, where strength, corrosion resistance, and durability are essential. Despite having its production base in China, ABLTi has created a global presence by selling to important foreign markets such as North America and Europe. This international presence emphasizes the company's significance as a key contributor to the global titanium alloy industry.

2. ADMA Products, Inc.

Headquarters: Hudson, Ohio, USA

ADMA Products, Inc., located in Hudson, Ohio, specializes in powder metallurgy for titanium and other sophisticated alloys. The firm specializes in the production of porous and completely dense titanium alloy components using pressing and sintering methods. These high-performance materials are widely used in aerospace, defense, and other important industries requiring strength and lightweight qualities. With a strong emphasis on innovation, ADMA assists industries seeking new materials for difficult situations. Although largely situated in the United States, its titanium goods are sold internationally, establishing ADMA as a trusted supplier within the titanium alloys industry.

3. ALLEGHENY TECHNOLOGIES INCORPORATED (ATI INC.)

Headquarters: Dallas, Texas, USA

Allegheny Technologies Incorporated (ATI Inc.), located in Dallas, Texas, USA, is a prominent manufacturer of specialty materials such as titanium alloys, superalloys, and advanced forging. ATI supplies high-performance materials engineered for durability and precision to critical industries such as aerospace, defense, medical, and industrial. Its titanium alloys are essential in aircraft construction, engines, and medical implants. ATI has operations throughout the United States and locations in about 16 additional countries, ensuring a strong international presence. The company's vast product line, global reach, and dedication to innovation make it a major competitor in the titanium alloys industry.

4. Altemp Alloys

Headquarters: Orange, California, USA

Altemp Alloys, headquartered in Orange, California, is a premier distributor and stocking provider of exotic and high-performance alloys, including titanium alloys like Ti-6Al-4V. The firm serves the aerospace, defense, and power generation industries, providing materials that exceed demanding performance and reliability requirements. Altemp's involvement in the titanium alloys industry is crucial as a supply partner, assuring the availability of specialty materials for high-demand applications. While the company's principal activities are based in the United States, its distribution network serves worldwide consumers as well. Altemp Alloys is known for its competence and dependability in the specialized alloys supply chain.

5. AMG (Advanced Metallurgical Group)

Headquarters: Amsterdam, Netherlands

AMG (Advanced Metallurgical Group), with headquarters in Amsterdam, Netherlands, and main operations in Wayne, Pennsylvania, USA, is a world leader in specialized materials. The titanium sector manufactures titanium master alloys and sophisticated materials for the aerospace, defense, and energy industries. Its emphasis on high-performance alloys corresponds to rising demand for lightweight, durable, and sustainable materials. AMG operates factories in Germany, the United States, China, India, Mexico, Brazil, and Sri Lanka, as well as sales offices across the world. With its strong global presence and scientific capabilities, AMG is a prominent force in the titanium alloys industry.

Are you ready to discover more about the titanium alloys market?

The report provides an in-depth analysis of the leading companies operating in the global titanium alloys market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- ABLTi Corporation

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- ADMA Products, Inc.

- ALLEGHENY TECHNOLOGIES INCORPORATED (ATI INC.)

- Altemp Alloys

- AMG (Advanced Metallurgical Group)

- Arcam

- Arconic Corporation

- ATI Inc.

- Daido Metal Co., Ltd

- Others

Conclusion

The Global Titanium Alloys Market Size is experiencing strong growth, driven by demand from aerospace, defense, medical, and automotive sectors. Their high strength-to-weight ratio, corrosion resistance, and biocompatibility make titanium alloys essential for aircraft components, surgical implants, and high-performance industrial applications. Technological advancements, including additive manufacturing and improved alloy designs, are expanding applications and efficiency. Sustainability initiatives, such as recycling titanium scrap, further support market development. Overall, titanium alloys are poised for continued growth, meeting the evolving needs of high-performance, durable, and sustainable applications across diverse industries worldwide.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?