United States Polycarbonate Market Size, Share, and COVID-19 Impact Analysis, By Grade (Flame Retardant Grade, Food Grade, Standard Purpose Grade, Medical Grade, and Others), By Application (Automotive, Medical Equipment, Packaging, Construction, Electrical, and Others), and US Polycarbonate Market Insights, Industry Trend, Forecasts to 2035

Industry: Chemicals & MaterialsUSA Polycarbonate Market Insights Forecasts to 2035

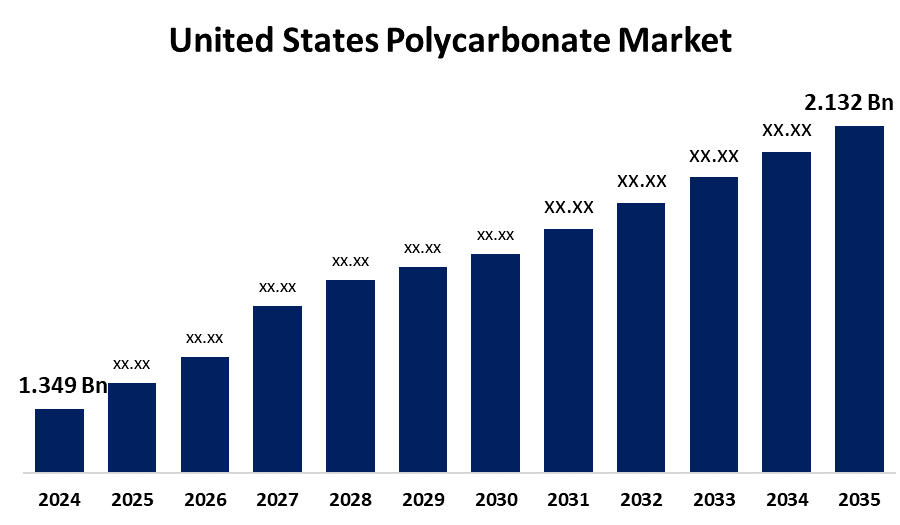

- The US Polycarbonate Market Size was Estimated at USD 1.349 Billion in 2024

- The Market Size is Expected to Grow at a CAGR of around 4.25% from 2025 to 2035

- The USA Polycarbonate Market Size is Expected to reach USD 2.132 Billion by 2035

Get more details on this report -

According to a research report published by Spherical Insights & Consulting, the US Polycarbonate Market Size is Anticipated to Reach USD 2.132 Billion by 2035, Growing at a CAGR of 4.25% from 2025 to 2035. The extensive use of polycarbonate materials in the electronics, medical, construction, and automotive industries accelerates the market growth.

Market Overview

The polycarbonate market involves the manufacturing and commercialization of polycarbonate, which is used in various industries such as medicine, automotive, construction, electronics, and packaging. Polycarbonate is a lightweight, long-lasting plastic. Among its many uses are compact discs and bulletproof windows. It is a great substitute for glass because of its strength and portability. The high mobility of carbonate segments in polycarbonate makes it a transparent thermoplastic that can tolerate considerable inelastic deformation. This transparent thermoplastic material is recyclable and environmentally friendly because it doesn't break or impact easily. Melted polycarbonate is molded under intense pressure to form the required shapes. It is a well-liked option for many applications due to its resilience and ability to maintain color under trying circumstances. Bisphenol A (BPA) and phosgene (COCl2) are the primary ingredients used in the production of PCs. The material has special qualities due to additional catalysts and additives. The hydroxyl groups are deprotonated in the first step by treating with sodium hydroxide, which creates a diphenoxide that combines with phosgene to yield a chloroformate.

A versatile material, polycarbonate plastic is found in many automobiles, appliances, and containers for food and drink. Its safe application in food-contact applications has been acknowledged by regulatory bodies such as the UK Food Standards Agency, the US FDA, and the Scientific Committee on Food of the European Commission. PC improves visual appeal, increases robustness, and allows for design flexibility. Its lightweight and transparent features make it ideal for automobile engineering and aerodynamic design. The superior creep resistance and stiffness of PC blends make them perfect for exterior and interior car body parts. Additionally, it is utilized in glazing applications such as skylights, security windows, shelters, and agricultural homes. PC offers toughness, dimensional stability, heat resistance, and clarity in medical applications. It can be sterilized using limited autoclave cycles, high-energy radiation, and ethylene oxide. The market for polycarbonate in the United States is an unambiguous testimony of the chemical industry's transition to sustainable and green solutions. Numerous new things have taken place in the industry.

Report Coverage

This research report categorizes the market for the US polycarbonate market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the US polycarbonate market. Recent market developments and competitive strategies such as expansion, product launch, development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the US polycarbonate market.

United States Polycarbonate Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 1.349 Billion |

| Forecast Period: | 2024-2035 |

| Forecast Period CAGR 2024-2035 : | 4.25% |

| 2035 Value Projection: | USD 2.132 Billion |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 170 |

| Tables, Charts & Figures: | 157 |

| Segments covered: | By Grade, By Application and COVID-19 Impact Analysis. |

| Companies covered:: | Lotte Chemical Corporation, Idemitsu Kosan Co. Ltd., RTP Company, Trinseo, Covestro AG, Entec Polymers, Mitsubishi Engineering Plastics Corporation, and Others. |

| Pitfalls & Challenges: | COVID-19 Impact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

A broad range of applications of the polycarbonate drives the market growth:

Superior chemical and physical qualities, such as thermoforming, high chemical resistance, lightweight, moisture resistance, high flexural strength, and cost-effectiveness, are driving a surge in demand for polycarbonate in the United States. Numerous end-use applications, such as construction, automotive, electrical, and medical equipment, have seen a surge in demand as a result of these qualities. Blood oxygenators, blood filters, face mask sheets, and blood reservoirs are all made with this product. Its adaptability in design makes it possible to produce OEMs and other plastic structures. It can be used to create sheets, fencing, protective barriers, and panels because it also provides high-impact resistance heating. The demand for the product should rise as a result of all of these variables.

Growing need for polycarbonate in flame-retardant products:

Blends of polycarbonate (PC), which have qualities like heat resistance, dimensional stability, and extreme toughness, have become commercially important in fireproof consumer goods, building & construction, and automotive applications. This maintains their toughness at low temperatures and provides flexibility for a variety of molding processes when combined with other materials, such as rubber. Fireproof products such as coffee makers, washing machines, CDs, helmets, facades, and shelters are made with PC blends. As a result of its excellent plastic standards, fireproof nature, and ability to integrate with other materials, PC is a perfect material for product manufacturing and is predicted to increase market growth.

Restraining Factors

The environmental concerns, high production costs, competition from alternatives, UV sensitivity, and supply chain disruptions may hinder the growth of the market.

Market Segmentation

The USA polycarbonate market share is classified into grade and application.

- The standard purpose grade segment held the largest share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The US polycarbonate market is segmented by grade into flame retardant grade, food grade, standard purpose grade, medical grade, and others. Among these, the standard purpose grade segment held the largest share in 2024 and is expected to grow at a significant CAGR during the forecast period. The segment growth is attributed to the durability, cost-effectiveness, weatherability, applicability for indoor and outdoor use, protective glazing, and clarity.

- The electrical segment accounted for the largest share in 2024 and is predicted to grow at a significant CAGR during the forecast period.

The US polycarbonate market is segmented by application into automotive, medical equipment, packaging, construction, electrical, and others. Among these, the electrical segment accounted for the largest share in 2024 and is predicted to grow at a significant CAGR during the forecast period. The segmental expansion is ascribed to an ideal electrical insulator, preventing short circuits, heat resistance, and flexibility.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the US polycarbonate market, along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Lotte Chemical Corporation

- Idemitsu Kosan Co. Ltd.

- RTP Company

- Trinseo

- Covestro AG

- Entec Polymers

- Mitsubishi Engineering Plastics Corporation

- Others

Recent Developments:

- In April 2024, Covestro introduced a new product line based on polycarbonate copolymers at the CHINAPLAS trade fair, offering enhanced properties and functionalities for a wider range of applications in industrial sectors, compared to standard products.

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at the United States, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the US polycarbonate market based on the below-mentioned segments:

US Polycarbonate Market, By Grade

- Flame Retardant Grade

- Food Grade

- Standard Purpose Grade

- Medical Grade

- Others

US Polycarbonate Market, By Application

- Automotive

- Medical Equipment

- Packaging

- Construction

- Electrical

- Others

Need help to buy this report?