Japan Metal Fabrication Fluid Market Size, Share, and COVID-19 Impact Analysis, By Product Type (Removal Fluids, Forming Fluids, Protective Fluids, Treating Fluids, and Others), By Fluid Type (Water-Based Fluids, Oil-Based Fluids, and Solvent-Based Fluids), By End Use (Automotive, Aerospace, Heavy Machinery, Metal Fabrication, Oil & Gas, Construction, and Others), and Japan Metal Fabrication Fluid Market Insights, Industry Trend, Forecasts to 2035

Industry: Chemicals & MaterialsJapan Metal Fabrication Fluid Market Insights Forecasts to 2035

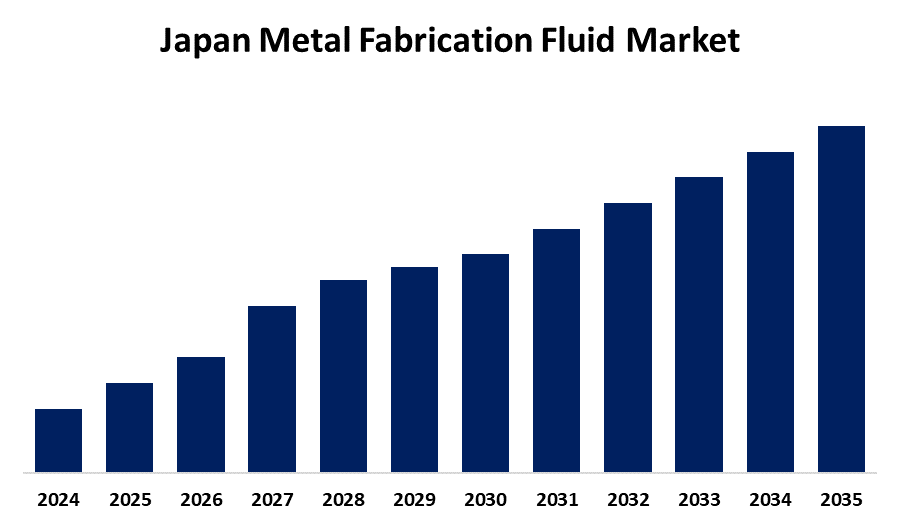

- The Japan Metal Fabrication Fluid Market Size is Expected to Grow at a CAGR of 5.1% from 2025 to 2035

- The Japan Metal Fabrication Fluid Market Size is Expected to Hold a Significant Share by 2035

Get more details on this report -

According to a Research Report Published by Spherical Insights & Consulting, the Japan Metal Fabrication Fluid Market is Expected to Hold a Significant Share by 2035, at a CAGR of 5.1% during the forecast period 2025-2035. The Japan metal fabrication fluid market is experiencing growth due to numerous factors, including increased demand from the automotive and aerospace industries, the development of advanced manufacturing technologies, and the rise in concerns regarding environmentally friendly and sustainable process practices.

Market Overview

The Japan metal fabrication fluid refers to a specialty in cutting, forming, protective, and treating fluids that are collectively known as metalworking fluids, which are used to increase machining operations through effective lubrication, cooling, chip removal, and corrosion protection. The fluids are extensively applied across the automotive, aerospace, electronics, machinery, and metal fabrication industries. The strengths of the Japanese market are mature industrial infrastructure, a strong R&D base (specifically nanotechnology-based fluids), and high-quality and safety standards. Opportunities are in new fluid additives, smart fluid management systems, and growth in niche areas like additive manufacturing and medical device production. The market growth is spurred by Japan's advanced base of manufacturing and growing demand for high-precision machining, spurred by expansion in the automobile and aerospace sectors. The government encourages innovation through regulations favoring biodegradable fluids and safety standards and Industry 4.0, and green manufacturing initiatives.

Report Coverage

This research report categorizes the market for the Japan metal fabrication fluid market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Japan metal fabrication fluid market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Japan metal fabrication fluid market.

Japan Metal Fabrication Fluid Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Forecast Period: | 2024-2035 |

| Forecast Period CAGR 2024-2035 : | 5.1% |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 150 |

| Tables, Charts & Figures: | 130 |

| Segments covered: | By Product Type, By Fluid Type and COVID-19 Impact Analysis. |

| Companies covered:: | Yushiro Chemical Industry Co., Ltd., ExxonMobil, Shin-Etsu Chemical Co., Ltd., Fuchs, Idemitsu Kosan, Mitsubishi Chemical Corporation, Quaker Houghton, Sumitomo Chemical Co., Ltd., Blaser Swisslube, ENEOS Corporation, DIC Corporation and Others. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

Increased application of high-precision machining and efficient metalworking operations fuels fluid demand. Advances such as bio-based and synthetic fluids increase performance while being environmentally friendly. Further, the demand for sustainability and adoption of Industry 4.0 technologies fuels the uptake of smart, energy-saving fluids. Government policies to promote innovation and environmental consciousness further propel market demand in industrial applications.

Restraining Factors

The Japan metal fabrication fluid market is constrained by rigorous environmental rules, costly disposal, and rising worker safety issues. Further, the move towards dry machining and fluidless technologies can cut down on conventional fluid consumption in some processes.

Market Segmentation

The Japan metal fabrication fluid market share is classified into product type, fluid type, and end use.

- The removal fluids segment held a significant share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Japan metal fabrication fluid market is segmented by product type into removal fluids, forming fluids, protective fluids, treating fluids, and others. Among these, the removal fluids segment held a significant share in 2024 and is expected to grow at a significant CAGR during the forecast period. This is due to these liquids finding their way to cooling and lubricating applications on the work tools and workpiece, thereby helping to decrease the heat and friction involved in metalworking processes. This improves the manufacturing processes, increases the operational life of the costly machinery and tools, decreases the cost of maintaining them, as well as improves productivity.

- The water-based fluids segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Japan metal fabrication fluid market is segmented by fluid type into water-based fluids, oil-based fluids, and solvent-based fluids. Among these, the water-based fluids segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period. This is owing to their higher cooling and lubrication characteristics, eco-friendliness, and adherence to severe regulations, they find applications in high-precision and green manufacturing processes.

- The automotive segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Japan metal fabrication fluid market is segmented by end use into automotive, aerospace, heavy machinery, metal fabrication, oil & gas, construction, and others. Among these, the automotive segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period. This is attributed to the nation's strong auto manufacturing sector. Demand for high-precision machining, enhanced efficiency, and high quality in auto production fuels intense use of metalworking fluids, enabling consistent market growth in this category.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Japan metal fabrication fluid market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Yushiro Chemical Industry Co., Ltd.

- ExxonMobil

- Shin-Etsu Chemical Co., Ltd.

- Fuchs

- Idemitsu Kosan

- Mitsubishi Chemical Corporation

- Quaker Houghton

- Sumitomo Chemical Co., Ltd.

- Blaser Swisslube

- ENEOS Corporation

- DIC Corporation

- Others

Recent Developments:

- In April 2025, Quaker Houghton and Idemitsu Kosan Co., Ltd. entered into a strategic alliance in Japan to sell Quaker Houghton's water-soluble metalworking fluids in addition to IKC's petroleum-based products. The partnership broadens their range for significant industries such as the automotive and aerospace industries, providing additional value to customers. Their combined product line will become accessible to IKC customers and partners beginning late 2025.

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at Japan, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the Japan metal fabrication fluid market based on the below-mentioned segments:

Japan Metal Fabrication Fluid Market, By Product Type

- Removal Fluids

- Forming Fluids

- Protective Fluids

- Treating Fluids

- Others

Japan Metal Fabrication Fluid Market, By Fluid Type

- Water-Based Fluids

- Oil-Based Fluids

- Solvent-Based Fluids

Japan Metal Fabrication Fluid Market, By End Use

- Automotive

- Aerospace

- Heavy Machinery

- Metal Fabrication

- Oil & Gas

- Construction

- Others

Need help to buy this report?