Japan Magnetic Separator Market Size, Share, and COVID-19 Impact Analysis, By Product (Magnetic Drum Separator, Magnetic Roller Separator, Over band/Cross Belt Separator, Magnetic Pulley Separator, Eddy Current Separator, and Others), By Intensity (High-Intensity Magnetic Separator, Medium-Intensity Magnetic Separator, and Low-Intensity Magnetic Separator), By Industry (Mining and Recycling), and Japan Magnetic Separator Market Insights, Industry Trend, Forecasts to 2035

Industry: Machinery & EquipmentJapan Magnetic Separator Market Insights Forecasts to 2035

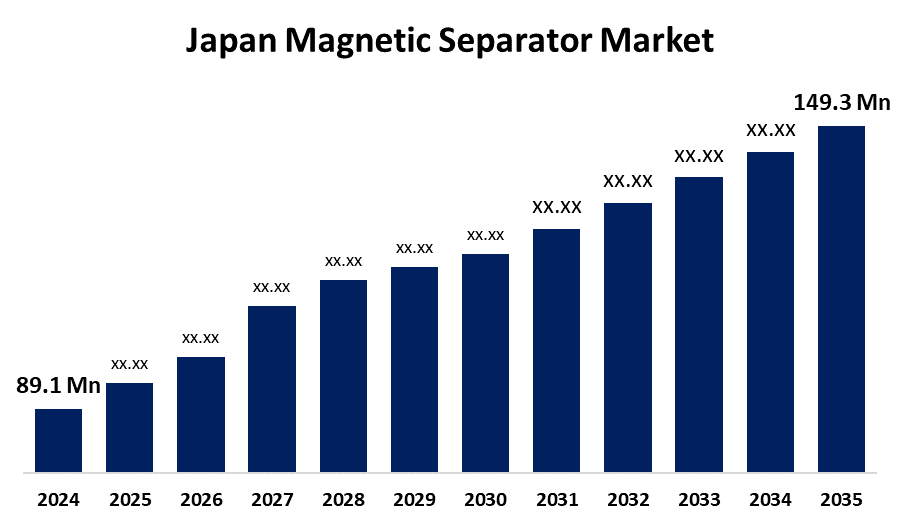

- The Japan Magnetic Separator Market Size Was Estimated at USD 89.1 Million in 2024

- The Market Size is Expected to Grow at a CAGR of around 4.8% from 2025 to 2035

- The Japan Magnetic Separator Market Size is Expected to Reach USD 149.3 Million by 2035

Get more details on this report -

According to a research report published by Spherical Insights & Consulting, The Japan Magnetic Separator Market Size is anticipated to reach USD 149.3 Million by 2035, growing at a CAGR of 4.8% from 2025 to 2035. The Japan magnetic separator market is expanding with increasing industrial demand for high-purity materials, stringent environmental legislation, and technological innovation. The key drivers are effective contaminant elimination in food, drugs, recycling, and Japan's focus on automation and green manufacturing.

Market Overview

The Japam magnetic separator market refers to the machinery utilizing magnetic fields, permanent or electromagnetic to remove ferrous and non-ferrous materials from industrial streams. They are applied to various industries, such as mining, recycling, food processing, pharmaceuticals, and HVAC. Advantages of the local market are high technological process, energy efficient design, and automation-friendly features. Opportunities in growing industrial automation, HVAC fluid cleanliness trends, and smart infrastructure retrofits. Expansion is driven by Japan's high-tech manufacturing base, electronics, automotive, and precision machinery industries, which drive material purity and quality demand. Government programs are financial incentives for recycling infrastructure, promotion of green building and energy efficiency initiatives, and subsidies under the Waste Management and Basic Recycling acts.

Report Coverage

This research report categorizes the market for the Japan magnetic separator market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Japan magnetic separator market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Japan magnetic separator market.

Japan Magnetic Separator Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Market Size in 2024: | USD 89.1 Million |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | 4.8% |

| 2035 Value Projection: | USD 149.3 Million |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 216 |

| Tables, Charts & Figures: | 110 |

| Segments covered: | By Product, By Intensity and By Industry |

| Companies covered:: | Eriez Manufacturing, Nippon Magnetics Inc., Kanetec Co., Ltd., Noritake Co., Ltd., Osaka Magnet Co., Ltd., Toshiba Materials Co., Ltd., Dowa Holdings Co., Ltd., Showa Denko K.K., Hitachi Industrial Equipment Systems Co., Ltd., Epiroc Japan, Sumitomo Heavy Industries Ltd., and Others |

| Pitfalls & Challenges: | COVID-19 Impact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The Japan market for magnetic separators is fueled by the nation's sophisticated manufacturing industry, regulatory requirements for the environment, and increased focus on sustainability. Automotive, electronics, and food processing industries require high material cleanliness, which drives adoption. Recycling and waste reduction policies encouraged by the government, as well as more automation and energy-saving technologies, also contribute to market growth. Also, the movement towards clean energy infrastructure and smart factories supports increased demand for separation systems that are reliable, particularly high-gradient and rare-earth magnetic solutions in precision applications.

Restraining Factors

The Japan market for magnetic separators is hindered by factors such as manufacturing and raw material expenses, rivalry from substitute technologies for separation, and strict environmental regulations. Adoption is further challenged by supply chain disruptions, integration complexity, and specialized expertise requirements, particularly among small businesses.

Market Segmentation

The Japan magnetic separator market share is classified into product, intensity, and industry.

- The magnetic drum separator segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Japan magnetic separator market is segmented by product into magnetic drum separator, magnetic roller separator, over band/cross belt separator, magnetic pulley separator, eddy current separator, and others. Among these, the magnetic drum separator segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period. This is owing to their adaptability, and integration with gravity separators for various industrial purposes is also possible. Magnetic drum separators are much in demand because of benefits such as increased safety of operation, minimal maintenance requirements, and the provision of protection to machinery like crushers and grinders.

- The high-intensity magnetic separator segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Japan magnetic separator market is segmented by intensity into high-intensity magnetic separator, medium-intensity magnetic separator, and low-intensity magnetic separator. Among these, the high-intensity magnetic separator segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period. This is attributed to the demand for high-intensity magnetic (HIM) separators are fueled by their critical application in mining and bulk recycling processes. Initiatives by recycling plants and mine operators to increase capacity output and improve operational efficiency contribute to increasing sales of these modern separation technologies.

- The mining segment held the largest market share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Japan magnetic separator market is segmented by industry into mining and recycling. Among these, the mining segment held a significant share in 2024 and is expected to grow at the largest market CAGR during the forecast period. This is due to the expanding mining activities in different regions, and the pressure to increase automation in these plants is fueling the need for magnetic separators since industries want effective, dependable solutions to increase material separation and overall production within the mining industry.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Japan magnetic separator market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Eriez Manufacturing

- Nippon Magnetics Inc.

- Kanetec Co. Ltd.

- Noritake Co. Ltd.

- Osaka Magnet Co. Ltd.

- Toshiba Materials Co. Ltd.

- Dowa Holdings Co. Ltd.

- Showa Denko K.K.

- Hitachi Industrial Equipment Systems Co. Ltd.

- Epiroc Japan

- Sumitomo Heavy Industries Ltd.

- Others

Recent Developments:

- In September 2024, Dowa Holdings completed the third plant for Eco Recycle Co. Ltd. in Odate City, Akita Prefecture. This expansion doubles recycling capacity for home appliances and electronic waste. The facility features advanced machinery, including magnetic separators, to improve sorting accuracy and boost overall recycling efficiency.

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at Japan, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the Japan magnetic separator market based on the below-mentioned segments:

Japan Magnetic Separator Market, By Product

- Magnetic Drum Separator

- Magnetic Roller Separator

- Over band/Cross Belt Separator

- Magnetic Pulley Separator

- Eddy Current Separator

- Others

Japan Magnetic Separator Market, By Intensity

- High-Intensity Magnetic Separator

- Medium-Intensity Magnetic Separator

- Low-Intensity Magnetic Separator

Japan Magnetic Separator Market, By Industry

- Mining

- Recycling

Need help to buy this report?