Germany Concrete Digital Manufacturing Market Size, Share, and COVID-19 Impact Analysis, By Component (Software, Services), By Process Type (Computer-Based Designing, Computer-Based Simulation, Computer 3D Visualization, Analytics, and Others), and Germany Digital Manufacturing Market Insights, Industry Trend, Forecasts to 2035

Industry: Construction & ManufacturingGermany Digital Manufacturing Market Size Insights Forecasts to 2035

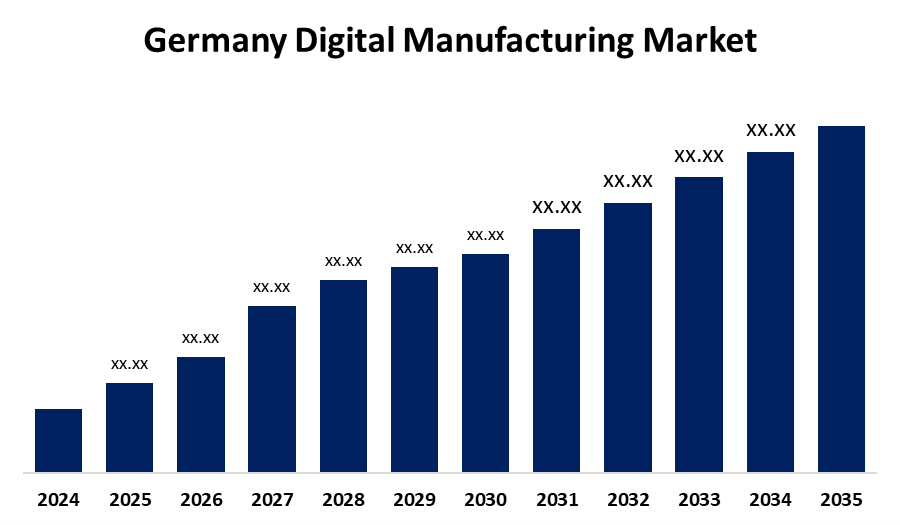

- The Germany Digital Manufacturing Market Size is Expected to Grow at a CAGR of around 4.11% from 2025 to 2035.

- The Germany Digital Manufacturing Market Size is Expected to hold a significant Share by 2035.

Get more details on this report -

According to a Research Report Published by Spherical Insights & Consulting, the Germany Digital Manufacturing Market Size is Expected to Grow at a CAGR of 4.11% during the forecast period 2025-2035. The market is driven by several key factors including the adoption of Industry 4.0, increasing automation, and the integration of technologies like AI and IoT.

Market Overview

Germany Digital Manufacturing Market Size has referred to the technology of advanced digital technologies such as Internet of Things (IOT), Artificial Intelligence (AI), Robotics, Cloud Computing and Data Analytics in various industries in Germany. It emphasizes the change of traditional manufacturing in smart, connected and highly automated systems aimed at increasing market efficiency, flexibility and productivity. This includes applications such as forecast maintenance, real -time monitoring, and digital twin modeling and smart factory operations. Inspired by Germany's strong industrial base and commitment to industry 4.0, the market plays an important role in shaping the future of manufacturing in the country. Germany offers adequate market opportunities in digital manufacturing, especially in terms of industry 4.0. The country's strong industrial base, especially in motor vehicles and machinery, combined with government initiatives such as digital strategy 2025 and industry 4.0 initiatives, drives growth in the region. The German government is actively supporting the digital change of its manufacturing sector through various initiatives and funding programs, mainly within the broad structure of "industry 4.0". These efforts focus on digitization, innovation and stability with special emphasis on advanced technologies and their integration in manufacturing processes.

Report Coverage

This research report categorizes the market for the Germany digital manufacturing market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Germany digital manufacturing market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Germany digital manufacturing market.

Germany Digital Manufacturing Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2024 |

| Forecast Period: | 2025-2035 |

| Forecast Period CAGR 2025-2035 : | 4.11% |

| Historical Data for: | 2020-2023 |

| No. of Pages: | 147 |

| Tables, Charts & Figures: | 125 |

| Segments covered: | Germany Digital Manufacturing Market Size is Expected to Grow at a CAGR of 4.11% during the forecast period 2025-2035. |

| Companies covered:: | Siemens, SAP, Bosch, Volkswagen, BMW, and Other key vendors |

| Pitfalls & Challenges: | COVID-19 Empact, Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The extensive use of Industry 4.0, which integrates IoT, AI, robots, and automation to improve operational efficiency and flexibility, is propelling the digital manufacturing industry in Germany. Implementation is accelerated by strong government backing through funding initiatives like Manufacturing-X and the Digital Hub Initiative. Germany's digital advantage is further strengthened by its strong SME and research clusters, high robot density, and cutting-edge additive manufacturing environment.

Restraining Factors

The Germany digital manufacturing market faces several preventive factors that obstruct its adoption on its full scale. High early investment costs in advanced technologies such as IOT, AI and robotics serve as a major barrier for small and medium -sized enterprises. Additionally, the complexity of integrating digital devices with heritage systems creates operational challenges. The lack of skilled professionals with specialization in digital manufacturing processes leads to market development. In addition, concerns related to data secrecy, cyber security and regulatory compliance in highly automated environment continue to continue significant obstacles for comprehensive implementation.

Market Segmentation

The Germany digital manufacturing market share is classified into component and process type.

- The software products segment held the largest share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Germany digital manufacturing market is segmented by component into software, services. Among these, the software segment held the largest share in 2024 and is expected to grow at a significant CAGR during the forecast period. This dominance is driven by the increasing adoption of cloud computing, which fuels demand for cloud-based software solutions. Additionally, the focus on innovative technologies like AI and machine learning is further boosting the software sector.

- The computer-based simulation segment dominated the market share in 2024 and is expected to grow at a significant CAGR during the forecast period.

The Germany digital manufacturing market is segmented by process type into computer-based designing, computer-based simulation, computer 3d visualization, analytics, and others. Among these, the computer-based simulation segment dominated the market share in 2024 and is expected to grow at a significant CAGR during the forecast period. This is primarily because simulation tools enable manufacturers to virtually replicate and analyze real-world scenarios, optimizing processes, testing design changes, and enhancing overall operational efficiency.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Germany digital manufacturing market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Siemens

- SAP

- Bosch

- Volkswagen

- BMW

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting and Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Market Segment

This study forecasts revenue at Germany, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the Germany digital manufacturing market based on the below-mentioned segments:

Germany Digital Manufacturing Market, By Component

- Software

- Services

Germany Digital Manufacturing Market, By Process Type

- Computer-Based Designing

- Computer-Based Simulation

- Computer 3D Visualization

- Analytics

- Others

Need help to buy this report?