Germany Automotive Parts Aluminum Die Casting Market Size, Share, and COVID-19 Impact Analysis, By Production Process (Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, and Gravity Die Casting), By Application Type (Body Parts, Engine Parts, Transmission Parts, Battery & Related Components, and Others), and Germany Automotive Parts Aluminum Die Casting Market Insights, Industry Trend, Forecasts to 2033

Industry: Automotive & TransportationGermany Automotive Parts Aluminum Die Casting Market Insights Forecasts to 2033

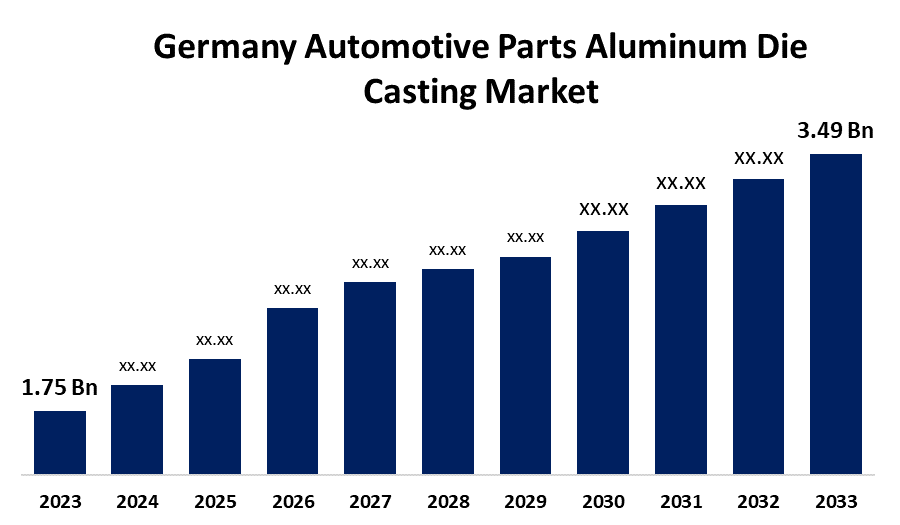

- The Germany Automotive Parts Aluminum Die Casting Market Size was valued at USD 1.75 Billion in 2023.

- The Germany Automotive Parts Aluminum Die Casting Market Size is Growing at a CAGR of 7.15% from 2023 to 2033

- The Germany Automotive Parts Aluminum Die Casting Market Size is Expected to reach USD 3.49 Billion by 2033

Get more details on this report -

The Germany Automotive Parts Aluminum Die Casting Market Size is anticipated to exceed USD 3.49 Billion by 2033, growing at a CAGR of 7.15% from 2023 to 2033. The growing domestic demand and the country’s strong export-oriented automotive sector are driving the Germany automotive parts aluminum die casting market.

Market Overview

The automotive parts aluminum die casting market refers to the production of automotive components using the die casting process with aluminum as the primary material. In the automotive aluminum die casting process, molten aluminum is forced under high pressure into a steel die mold to create a precision-engineered automotive part. The method allows for the creation of intricate shapes with high accuracy and a smooth surface finish. There is an increasing market demand for automotive parts aluminum die casting due to the upsurging demand for lightweight and strong automotive parts. Further, the strict environmental regulations and CAFÉ standards across diverse regions are driving the adoption of this die-casting process.

Report Coverage

This research report categorizes the market for the Germany automotive parts aluminum die casting market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the Germany automotive parts aluminum die casting market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the Germany automotive parts aluminum die casting market.

Germany Automotive Parts Aluminum Die Casting Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2023 |

| Market Size in 2023: | USD 1.75 Billion |

| Forecast Period: | 2023-2033 |

| Forecast Period CAGR 2023-2033 : | 7.15% |

| 2033 Value Projection: | USD 3.49 Billion |

| Historical Data for: | 2019-2022 |

| No. of Pages: | 210 |

| Tables, Charts & Figures: | 123 |

| Segments covered: | By Production Process, By Application Type and COVID-19 Impact Analysis |

| Companies covered:: | Sipra Engineers Pvt. Ltd., Dynacast International Inc., Jaya Hind Industries Ltd., Sandhar Technologies Ltd., Sundaram Clayton Ltd., Linamar Corporation, Georg Fischer Ltd., GIBBS, Endurance Technologies Limited, NEMAK, and Others key Vendors. |

| Pitfalls & Challenges: | COVID-19 Empact, Challenge, Future, Growth, & Analysis. |

Get more details on this report -

Driving Factors

The incorporation of die casting methods for manufacturing lightweight and strong materials in the automobile industry is driving the market demand for automotive parts aluminium die casting. Further, the growing IoT innovation and industry 4.0 for enhancing the aluminum die casting tool procedures for cost effectiveness, producing quality products, and increasing productivity is expected to propel the market growth. Germany is considered the global leader of the export-oriented automotive industry in both domestic and international markets. The expanding automotive sector and the country’s export economy are contributing to driving the market growth.

Restraining Factors

The availability of magnesium as a substitute for aluminum alloy is challenging the market. Further, the rising economic crisis is also responsible for restraining the market growth.

Market Segmentation

The Germany automotive parts aluminum die casting market share is classified into production process and application type.

- The pressure die casting segment dominated the automotive parts aluminum die casting market in 2023 and is expected to grow at a significant CAGR during the forecast period.

Based on the production process, the Germany automotive parts aluminum die casting market is divided into pressure die casting, vacuum die casting, squeeze die casting, and gravity die casting. Among these, the pressure die casting segment dominated the automotive parts aluminum die casting market in 2023 and is expected to grow at a significant CAGR during the forecast period. In pressure die casting, molten aluminum is forced under high pressure into a mold cavity to create the desired shape. The ability of die casting to produce high-precision, complex components at scale is driving the market growth in the pressure die casting segment.

- The body parts segment dominates the market with the largest market share and is expected to grow at a significant CAGR during the projected timeframe.

Based on the application type, the Germany automotive parts aluminum die casting market is divided into body parts, engine parts, transmission parts, battery & related components, and others. Among these, the body parts segment dominates the market with the largest market share and is expected to grow at a significant CAGR during the projected timeframe. Automotive parts die casting is used in automotive body parts such as engine blocks, transmission housings, and chassis components due to its ability to produce lightweight, complex, and strong components. The use of body parts in automotive manufacturing for aesthetic appeal and structural integrity is propelling the market demand.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the Germany automotive parts aluminum die casting market along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Sipra Engineers Pvt. Ltd.

- Dynacast International Inc.

- Jaya Hind Industries Ltd.

- Sandhar Technologies Ltd.

- Sundaram Clayton Ltd.

- Linamar Corporation

- Georg Fischer Ltd.

- GIBBS

- Endurance Technologies Limited

- NEMAK

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In April 2025, CN Newtech plans to establish a German subsidiary to enter the European automotive parts market.

Market Segment

This study forecasts revenue at Germany, regional, and country levels from 2020 to 2033. Spherical Insights has segmented the Germany Automotive Parts Aluminum Die Casting Market based on the below-mentioned segments:

Germany Automotive Parts Aluminum Die Casting Market, By Production Process

- Pressure Die Casting

- Vacuum Die Casting

- Squeeze Die Casting

- Gravity Die Casting

Germany Automotive Parts Aluminum Die Casting Market, By Application Type

- Body Parts

- Engine Parts

- Transmission Parts

- Battery & Related Components

- Others

Need help to buy this report?