Global Conformal Coating Market Size, Share, and COVID-19 Impact Analysis, By Type (Acrylic, Silicone, Epoxy, Urethane, and Parylene), By End-Use (Consumer Electronics, Automotive, Aerospace & Defense, Industrial and Telecommunication), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 - 2032

Industry: Chemicals & MaterialsGlobal Conformal Coating Market Insights Forecasts to 2032

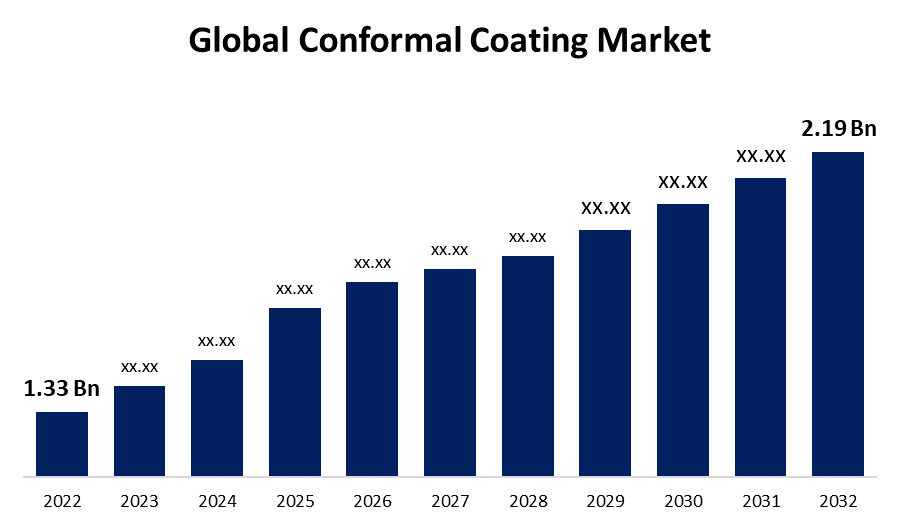

- The Global Conformal Coating Market Size was valued at USD 1.33 Billion in 2022.

- The Market Size is Growing at a CAGR of 5.1% from 2022 to 2032

- The Worldwide Conformal Coating Market Size is expected to reach USD 2.19 Billion by 2032

- Asia Pacific is expected to Grow the fastest during the forecast period

Get more details on this report -

The Global Conformal Coating Market size is anticipated to exceed USD 2.19 Billion by 2032, growing at a CAGR of 5.1% from 2022 to 2032. This market is expected to grow as industries around the world continue to rely on electronics to run their businesses and consumers demand more durable and robust electronic products.

Market Overview

Conformal coatings are specialized protective coatings that are applied to printed circuit boards (PCBs) and electronic components to protect them from environmental factors such as moisture, chemicals, dust, and extreme temperature. These coatings improve the dependability and longevity of electronic devices, making them suitable for use in a variety of applications ranging from consumer electronics to the aerospace and automotive industries. Because of increased demand for electronics and the proliferation of IoT devices that require robust protection against harsh operating conditions, the market for conformal coatings has grown significantly. Conformal coating manufacturers are constantly innovating to create coatings with improved performance properties, such as increased durability, chemical resistance, and ease of application. Geographically, the market extends North America, Europe, Asia-Pacific, and other regions, with Asia-Pacific emerging as the dominant player, owing to the presence of numerous electronics manufacturing hubs. Among the key market players are Henkel AG & Co. KGaA, Dow Corning, Electrolube, and H.B. Fuller. As technology advances and electronic components become more integrated into our daily lives, the global conformal coating market is poised for continued growth as a critical component in ensuring electronic device reliability and longevity.

Report Coverage

This research report categorizes the market for the global conformal coating market based on various segments and regions and forecasts revenue growth and analyzes trends in each submarket. The report analyses the key growth drivers, opportunities, and challenges influencing the conformal coating market. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger, and acquisition have been included to draw the competitive landscape in the market. The report strategically identifies and profiles the key market players and analyses their core competencies in each sub-segment of the conformal coating market.

Global Conformal Coating Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2022 |

| Market Size in 2022: | USD 1.33 Billion |

| Forecast Period: | 2022-2032 |

| Forecast Period CAGR 2022-2032 : | 5.1% |

| 2032 Value Projection: | USD 2.19 Billion |

| Historical Data for: | 2018-2021 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 100 |

| Segments covered: | By Type, By End-Use, By Region |

| Companies covered:: | Chemtronics, Henkel AG & Company, Shin-Etsu Chemical Co., Ltd, Dow, Chase Corporation, Dymax Corporation, Specialty Coating Systems, Electrolube, H.B. Fuller, M.G. Chemicals, and other key venders |

| Pitfalls & Challenges: | COVID-19 Empact,Challenges, Future, Growth, & Analysis |

Get more details on this report -

Driving Factors

The proliferation of electronic devices in a variety of industries, such as consumer electronics, automotive, aerospace, and healthcare, has increased demand for conformal coatings. As more electronic components are integrated into products, protecting them from environmental factors becomes increasingly important. The demand for precise and thin conformal coatings has increased as electronic devices have become smaller and more compact. Manufacturers are developing coatings that provide protection without adding significant thickness, driving market growth even further. Conformal coatings that are environmentally friendly and comply with regulations such as RoHS (Restriction of Hazardous Substances) are gaining traction. As environmental consciousness grows, there is a shift towards more sustainable coating solutions, propelling market demand. Ongoing research and development efforts have led to the creation of advanced conformal coatings with improved properties. These coatings offer better protection, ease of application, and longer lifespan, encouraging their adoption across industries.

Restraining Factors

Conformal coatings, particularly high-performance and specialized coatings, can be quite costly. This cost barrier may deter smaller manufacturers and startups from using conformal coatings, resulting in subpar protection for their electronic products. Conformal coating application can be a time-consuming and labor-intensive process. It necessitates specialized equipment and skilled personnel, which raises production costs and may result in inconsistencies in coating quality.

Market Segmentation

The Global Conformal Coating Market share is classified into type and end-use.

- The acrylic segment is expected to hold the largest share of the global conformal coating market during the forecast period.

The global conformal coating market is categorized by type into Acrylic, Silicone, Epoxy, Urethane, and Parylene. Among these, the acrylic segment is expected to hold the largest share of the global conformal coating market during the forecast period. Acrylic coatings are well-known for their ease of application, quick curing time, and high moisture resistance. They provide adequate resistance to humidity, chemicals, and dust. Acrylic coatings are commonly used in consumer electronics, automotive electronics, and general-purpose printed circuit boards (PCBs).

- The automotive segment accounted for a significant share of the global conformal coating market in 2022.

Based on the end-use, the global conformal coating market is divided into Consumer Electronics, Automotive, Aerospace & Defense, Industrial and Telecommunication. Among these, the automotive segment accounted for a significant share of the global conformal coating market in 2022. Given the growing integration of electronics in modern vehicles and the need for robust protection against temperature fluctuations, vibration, and moisture, the automotive segment is a significant contributor to the conformal coating market. Conformal coatings are critical in the automotive industry for protecting electronic components such as engine control units (ECUs), sensors, and infotainment systems.

Regional Segment Analysis of the Global Conformal Coating Market

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia-Pacific (China, Japan, India, Rest of APAC)

- South America (Brazil and the Rest of South America)

- The Middle East and Africa (UAE, South Africa, Rest of MEA)

North America is anticipated to hold a significant share of the global conformal coating market over the predicted timeframe.

Get more details on this report -

North America is projected to hold a significant share of the global conformal coating market over the predicted years. Because of its established electronics and automotive industries, North America has traditionally held a significant share of the global conformal coating market. The presence of a robust electronics manufacturing sector, particularly in the United States, has resulted in a mature conformal coating market in North America. The region places a premium on innovation as well as adherence to stringent quality and environmental standards.

Asia Pacific is expected to grow at the fastest pace in the global conformal coating market during the forecast period. Due to its massive electronics manufacturing capacity and increasing technological innovation, Asia-Pacific has emerged as a dominant player in the global conformal coating market in recent years. Asia-Pacific, particularly China, South Korea, Japan, and Taiwan, is a major producer of consumer electronics, telecommunications devices, and automotive components. The rapid industrialization and electronics production in the region drive the demand for conformal coatings.

Europe holds a significant share of the global conformal coating market, owing to its well-established industrial base and emphasis on sustainability. The automotive, aerospace, and industrial manufacturing industries drive Europe's conformal coating market. Environmental regulations in the European Union have also increased the use of eco-friendly conformal coatings.

Competitive Analysis:

The report offers the appropriate analysis of the key organizations/companies involved within the global conformal coating along with a comparative evaluation primarily based on their product offering, business overviews, geographic presence, enterprise strategies, segment market share, and SWOT analysis. The report also provides an elaborative analysis focusing on the current news and developments of the companies, which includes product development, innovations, joint ventures, partnerships, mergers & acquisitions, strategic alliances, and others. This allows for the evaluation of the overall competition within the market.

List of Key Companies

- Chemtronics

- Henkel AG & Company

- Shin-Etsu Chemical Co., Ltd

- Dow

- Chase Corporation

- Dymax Corporation

- Specialty Coating Systems

- Electrolube

- H.B. Fuller

- M.G. Chemicals

- Others

Key Target Audience

- Market Players

- Investors

- End-users

- Government Authorities

- Consulting And Research Firm

- Venture capitalists

- Value-Added Resellers (VARs)

Recent Developments

- In June 2023, Henkel and Labori International have entered into a distribution agreement. Henkel will retain responsibility for overseeing the brand's business operations during a transitional period, according to the terms of the agreement.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2020 to 2032. Spherical Insights has segmented the Global Conformal Coating Market based on the below-mentioned segments:

Global Conformal Coating Market, By Type

- Acrylic

- Silicone

- Epoxy

- Urethane

- Parylene

- Others

Global Conformal Coating Market, By End-Use

- Consumer Electronics

- Automotive

- Aerospace & Defense

- Industrial and Telecommunication

- Others

Global Conformal Coating Market, By Region

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

Need help to buy this report?