Global Aluminum Scrap Recycling Market Size, Share & Trends, COVID-19 Impact Analysis Report, By Aluminum Scrap Type (Cast Aluminum, Aluminum Cans, Sheet Aluminum and Others), By Category (New Scrap, Old Scrap), By Application (Building & Construction, Automotive, Electronics, Machinery & Equipment Packaging and Others), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2021 - 2030

Industry: Advanced MaterialsALUMINIUM SCRAP RECYCLING MARKET: OVERVIEW

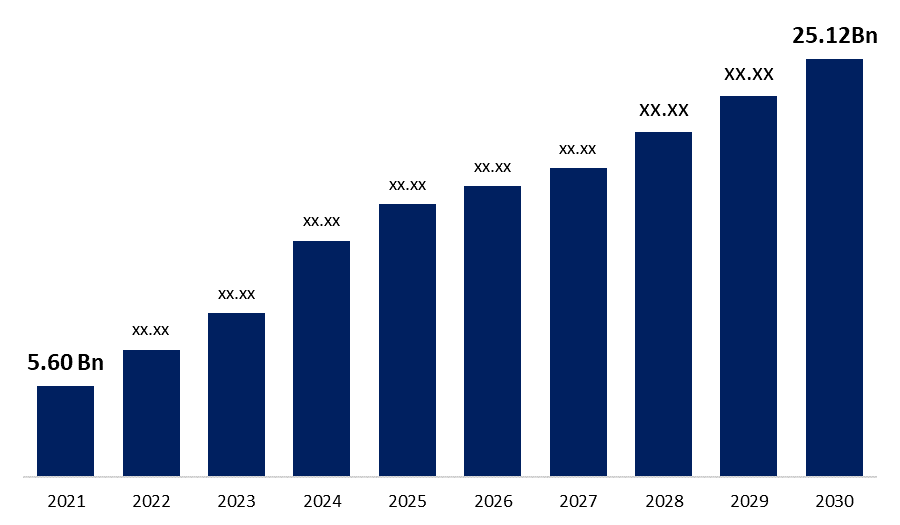

The Global Aluminum Scrap Recycling Market was valued at USD 5.60 billion in 2021 and is expected to reach USD 25.12 billion by 2030, growing at a CAGR of 8.16 % during 2021-2030. Aluminum (Al), also written aluminum, is a light silvery-white metal in the periodic table's major Group 13 (IIIa, or boron group). Aluminum is the most common nonferrous metal and the most prevalent metallic element in the Earth's crust. Aluminum is never found in its metallic form in nature due to its chemical activity, but its compounds can be found in varying degrees in practically all minerals, flora, and animals. Aluminum scrap recycling is the process of repurposing scrap aluminum for use in other products.

Get more details on this report -

Aluminum scrap is recycled by a process that involves melting, sorting, purifying, and solidifying the scrap. After silicon, aluminium is the world's second most abundant resource, and it has been utilized commercially for over a century. It is light in weight and exhibits malleability and ductility, among other qualities. It also has a good corrosion resistance feature and is employed as a critical component in practically all industries throughout the world. Rail, cars, marine vessels, airplanes, trucks, consumer durables, machinery, and packaging are all examples of where aluminum is employed.

COVID-19 ANALYSIS

The coronavirus epidemic has affected food and beverage, construction, automotive, packing, consumer products, and other businesses. Because individuals have been isolated over the world, the total demand for these industries has decreased. Governments have been obliged to shut down industrial activity to prevent the virus from spreading further. The production process has also been hampered by a lack of labor in the industry. Similarly, supply chain interruptions in different nations have lowered demand for a variety of products. Aluminium is widely employed in a variety of industries; therefore, demand is likely to fall as a result of plant closures and poor client demand. As a result, the aluminium scrap recycling market growth is hampered by the COVID-19 pandemic.

ALUMINIUM SCRAP RECYCLING MARKET: TREND

Technological Advancement in The Aluminium Scrap Recycling Industry Across Globe Propel Market Growth

In recent years, a slew of technological advancements has been implemented in scrap metal recycling yards to aid in the sorting and processing of waste. This technology was adopted to help speed up the process of manually sorting things, as well as to handle the changing nature of the complexity of materials in the waste stream and the complexity of items like electronics. The goal has been to enhance the amount of recycled material while also speeding up the processing. Overall, improved scrap sorting can assist businesses in producing cleaner batches of material for further processing. Much of the work that was once done by hand is now done by sensors and sorting machines. To sort non-magnetic metals, companies are experimenting with x-ray technologies and infrared scanning. Non-metals are identified using laser object detection (LOD), which allows them to be eliminated before processing. By preserving more recyclable material in a shorter amount of time, laser technology for scrap metal processing can result in significant savings.

As a result, more advanced techniques are required to identify the Laser-induced breakdown spectroscopy (LIBS) and solid-state recycling has been introduced to the aluminium scrap recycling business as a result of technological advancements. This is a recent trend that has aided in the expansion of the aluminium scrap recycling sector. LIBS is made up of a high-powered laser that can detect impurities in any physical state. To make the aluminium recycling process easier, solid-state recycling crushes and cleans recyclable metal pieces Substance.

Global Aluminum Scrap Recycling Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2021 |

| Market Size in 2021: | USD 5.60 Billion |

| Forecast Period: | 2021-2030 |

| Forecast Period CAGR 2021-2030 : | 8.16 % |

| 2030 Value Projection: | USD 25.12 Billion |

| Historical Data for: | 2017-2020 |

| No. of Pages: | 200 |

| Tables, Charts & Figures: | 120 |

| Segments covered: | COVID-19 Impact Analysis Report, By Aluminum Scrap Type, By Category, By Application, By Region |

| Companies covered:: | Sims Metal Management Kuusakoski Recycling DOWA HOLDINGS Co., Ltd. ArcelorMittal S.A. REAL ALLOY Commercial Metals Company Aurubis AGS TRIMET Aluminium Nupur Recyclers Arfin India Ltd Palco Recycle Industries Fervent Global LLP Chalco Aluminium Corporation Matalco Inc. AMAG Austria Metall AG China Hongqiao Group Limited RusAL Rio Tinto |

| Growth Drivers: | 1)The aluminum scrap recycling market is segmented by aluminium scrap type, category and application 2)The North America is dominating the market share of the global Aluminium Scrap Recycling. |

| Pitfalls & Challenges: | COVID-19 has the potential to impact the global market |

Get more details on this report -

ALUMINIUM SCRAP RECYCLING MARKET: DRIVERS

Increased Application of Aluminium in The Automobile Industry Boost the Market Growth

The automobile is the most prevalent mode of transportation on the planet. However, since the automotive industry focuses more on fuel efficiency, CO2 emissions reduction, and design, aluminium is becoming increasingly significant in modern vehicles. In 2014, the global automotive sector consumed 2.87 million tons of aluminum (excluding China). It is estimated to consume 4.49 million tons of aluminum per year by 2020. The increased use of aluminium in modern cars, as well as expanding automotive production, are key reasons for this expansion. Each kilogram of aluminum used in a vehicle reduces the vehicle's overall weight by one kilogram. As a result, more and more automotive parts, such as engine radiators, wheels, bumpers, suspension elements, engine cylinder blocks, gearbox bodies, and body parts such as hoods, doors, and even the frame, are constructed of aluminium. As a result, the percentage of aluminium in the overall weight of an ordinary car has steadily increased from 35 kg in the 1970s to 152 kg today. Experts predict that by 2025, the average amount of aluminium in a car would be 250 kg. Increased use of aluminium in the automobile industry and the rise in the adoption of aluminium recycling practices are the major factor that is expected to propel the market growth.

ALUMINIUM SCRAP RECYCLING MARKET: RESTRAINT

Environmental Problems Associated with Recycling Aluminum restraint Market Growth

There are many environmental problems associated due to the recycling of scrap aluminium these problems are the major challenges for the aluminium scrap recycling market. Here are some of the problems associated due to aluminium recycling. The recycling aluminum uses minimum energy that is used to produce new aluminium from bauxite. In various countries the waste disposal laws are different. Hence, these factors are the major restraint for the aluminum scrap recycling market.

ALUMINIUM SCRAP RECYCLING MARKET: SEGMENTATION

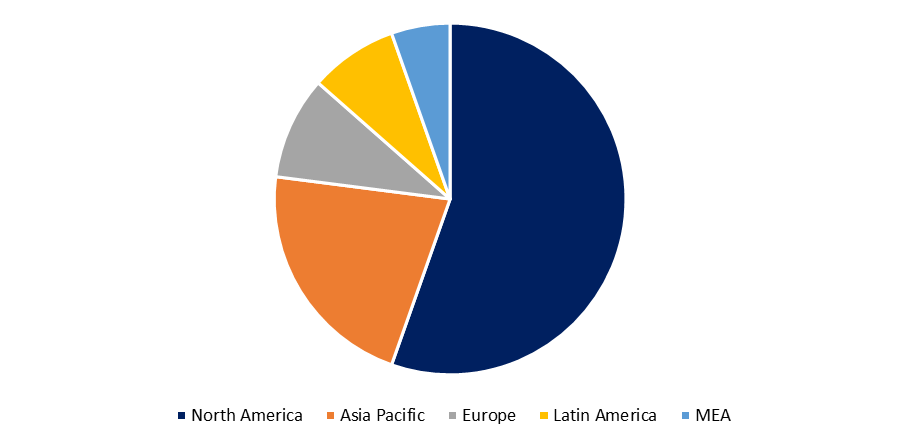

The aluminium scrap recycling market is segmented by aluminium scrap type, category and application. Based on the aluminium scrap type, the market has been segmented into cast aluminium, aluminium cans, sheet aluminium, and others. Based on the category, the market has been bifurcated into new scrap and old scrap. Based on the application, the market has been bifurcated into building & construction, automotive, electronics, machinery & equipment packaging, and others. Based on the Region, the market is categorized into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa.

ALUMINIUM SCRAP RECYCLING MARKET: BY REGION

Based on the Region, the Aluminium Scrap Recycling Market is categorized into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. The North America is dominating the market share of the global Aluminium Scrap Recycling. The demand for aluminium scrap recycling is mainly growing owing to the increasing use of aluminium in many products that’s why vice versa the scrap is increasing and it’s necessary to be recycled. For instance, data on global aluminium recycling has been issued by the International Aluminium Institute (IAI). As per IAI recycling data, one of the most recycled materials on the planet is aluminium. The global recycling efficiency rate is now around 76%. The economic and environmental benefits of aluminium waste are highlighted by high recycling rates in all regions.

Get more details on this report -

Africa has roughly 50 metal recycling plants, compared to more than 250 in other countries such as Europe. In Nigeria, it is estimated that only 13% of recyclable materials are reused, with essentially no systematic waste diversion mechanism. In Africa, a cleantech revolution is already underway, with recycling, renewable energy, and sustainable infrastructure initiatives. The primary breakthrough will be to integrate sustainable infrastructure with regional economic expansion. With the growth of the metals industry in the country, capacity expansion in recycling and sustainable systems will become increasingly vital. Without a sustainable strategy, all of the negative effects of mining, such as soil degradation, carbon emissions, fauna displacement, biodiversity loss, deforestation, and water and air contamination, will influence Africa's economic progress

Competitive Landscape

Global demand for aluminium is expected to treble by 2050 due to rapid population and economic expansion, with 50 percent to 60 percent of it coming from recycled metal. We need to develop and maintain high recycling rates around the world to create a sustainable circular economy, especially post-COVID. The major key vendors associated with Aluminum Scrap Recycling and solutions offerings are Nucor Corporation, Sims Metal Management, Kuusakoski Recycling, DOWA HOLDINGS Co., Ltd., ArcelorMittal S.A., REAL ALLOY, Commercial Metals Company, Aurubis AG, TRIMET Aluminium, and Kawashima Group among others.

Recent Development

- May 2019 - Nucor Corporation announced a capital investment in its bar mill in Darlington, South Carolina, that will add vacuum degassing to its engineered bar capabilities. The addition of this capability will allow the mill to produce engineered bar products that meet some of the industry's most stringent quality specifications. The vacuum degassing system is scheduled to go into service in late 2020.

- May 2019 - Aurubis AG acquired the Belgian-Spanish Metallo Group in order to pursue its multi-metal and recycling strategy more aggressively. With its attractive growth potential, the acquisition strengthens the company's multi-metal portfolio, particularly in the key metals copper, nickel, tin, zinc, and lead.

ALUMINIUM SCRAP RECYCLING MARKET: KEY PLAYERS

- Sims Metal Management

- Kuusakoski Recycling

- DOWA HOLDINGS Co., Ltd.

- ArcelorMittal S.A.

- REAL ALLOY

- Commercial Metals Company

- Aurubis AGS

- TRIMET Aluminium

- Nupur Recyclers

- Arfin India Ltd

- Palco Recycle Industries

- Fervent Global LLP

- Chalco Aluminium Corporation

- Matalco Inc.

- AMAG Austria Metall AG

- China Hongqiao Group Limited

- RusAL

- Rio Tinto

MARKET SCOPE

The reports also assist in understanding the dynamic and structure of the Aluminium Scrap Recycling market. The study serves as an investor's guide with its clear representation of competitive analysis of key competitors by product, price, raw material, product portfolio, growth plans, and regional presence in the market for Aluminium Scrap Recycling. Understanding the present use of the Secondary aluminium the production of secondary aluminium. Since it was first commercially produced, aluminium has been recycled. Nearly a third of the world's aluminium comes from secondary sources of consumption

Market Segments

Aluminum Scrap Recycling Market, By Aluminum Scrap Type

- Cast Aluminum

- Aluminum Cans

- Sheet Aluminum

- Others

Aluminum Scrap Recycling Market, By Category

- New Scrap

- Old Scrap

Aluminum Scrap Recycling Market, By Application

- Building & Construction

- Automotive

- Electronics

- Machinery & Equipment Packaging

- Others

Aluminum Scrap Recycling Market , By Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

Need help to buy this report?