Global Aerospace Cold Forgings Market Size, Share, and COVID-19 Impact Analysis, By Type (Custom Forging, Captive Forging, Catalog Forging), By Application (Airframe, Landing Gear, Nacelle Component), by Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2021 – 2030.

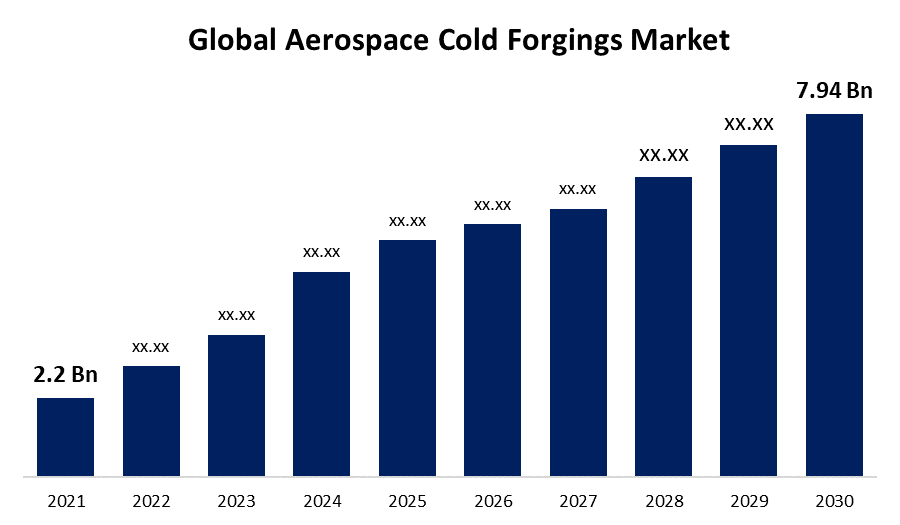

Industry: Aerospace & DefenseThe Global Aerospace Cold Forgings is expected to grow from USD 2.43 billion in 2021 to USD 6.00 billion by 2030, at a CAGR of 13.80% during the forecast period 2022-2030.

Get more details on this report -

Aerospace Cold Forgings Market: Overview

Aerospace Cold Forgings Market Size was valued at over USD 2.2 million in 2021 and is anticipated to grow at a CAGR of more than 8.5% over the forecast period. Deforming materials into high-strength components is the goal of the industrial process known as cold forging. High production precision, which is necessary for aviation parts and components, is ensured by the cold forging process. Cold-forged components with precise dimensions require little to no polishing. The increasing importance of aircraft structural dependability and the requirement for a high strength-to-weight ratio are two major factors influencing the market's growth. Changing trends toward effective manufacturing procedures, better material utilization, and lower forging energy are supporting industry share.

Traditional production processes are slower than cold forging. This has contributed to the growth of the market by making it possible to finish a significant amount of manufacturing in a shorter amount of time. The strict guidelines set forth by the IAQG for the production of aeronautical parts have aided in the adoption of the cold forgings technique. The aircraft cold forgings industry has benefited from this, enabling growth. The cold forging production method also considerably reduces material loss, which expands the market. By reducing energy requirements, improving precision, and lowering prices, sophisticated technologies like hydraulic forging presses that use EHF are being developed, which is expanding their market penetration. In order to increase their market share or streamline their business opportunities, industry players are investing a lot in R&D.

Global Aerospace Cold Forgings Market Report Coverage

| Report Coverage | Details |

|---|---|

| Base Year: | 2021 |

| Market Size in 2021: | USD 2.2 million |

| Forecast Period: | 2022-2030 |

| Forecast Period CAGR 2022-2030 : | 9.2 % |

| 2030 Value Projection: | USD 7.94 million |

| Historical Data for: | 2019-2020 |

| No. of Pages: | 210 |

| Tables, Charts & Figures: | 106 |

| Segments covered: | By Type, By Application, By Region |

| Companies covered:: | Precision Castparts Corp. Eramet, Scot Forge, ATI Metal Bharat Forge VSMPO-AVISMA Corporation Arconic Shaanxi Hongyuan Aviation Forging Co., Ltd. |

| Growth Drivers: | The aerospace cold forgings market is expected to expand because of an increase in the inclination of aircraft manufacturers for using aerospace components with tight dimensional tolerances as well as high surface finishes. |

| Pitfalls & Challenges: | The market may be hampered by a lack of experienced workers and the availability of composite materials with anti-corrosive qualities. |

Get more details on this report -

Aerospace Cold Forgings Market- Growth Factors

During the projection period, the need for strong aeroplane structures with a high strength-to-weight ratio and good structural dependability would likely increase. The aerospace cold forgings market is expected to expand because of an increase in the inclination of aircraft manufacturers for using aerospace components with tight dimensional tolerances as well as high surface finishes. The market value will increase as cost-effective materials are increasingly used to produce high-strength cold-forged products. Additionally, the manufacturing cycle time will improve with the elimination of heat treatment procedures like hardening and tempering, thus improving operational efficiency.

The growing requirement to lower aeroplane emission levels and improve fuel efficiency will support industry expansion even further. On the other hand, the sector is under threat from the expanding use of composite materials in the production of aircraft. Furthermore, the COVID-19 illness outbreak has completely destroyed the market. The demand for new aircraft fell as a result of the decline in passenger air traffic and the suspension of freight operations, which led to a decline in the usage of cold forging products. Nevertheless, a year after the crisis put an end to the business, demand is anticipated to show indications of restoration and the market will gain significant momentum in the coming years. On the other hand, by 2028, the fixed-wing platform segment will have 80% of the market share for aerospace cold forgings. The need for fixed-wing aircraft will rise dramatically as new air travel destinations are added, along with more air connecting routes. Cold-forged aircraft parts' low cost and great strength, as well as their growing use in structures, will significantly increase their durability and service life.

Aerospace Cold Forgings Market – Market Trends

- Rising demand in the commercial and defense aerospace industries.

- Developments in technology and collaborative enterprises.

- Growing numbers of passengers flying.

- A rise in low-cost carriers' presence.

- Rising demand for regional jets and rising tourists.

- Aerial rescue missions & law enforcement are using helicopters more frequently, which may lead to prospects for business growth. The industry value will be fuelled by the modern helicopters' expanding market share and rising orders and sales.

- Due to recent technical developments, the aerospace industry has experienced considerable growth. This is a key driver fuelling the expansion of the global market for aerospace cold forgings. Additionally, cold forging is more rapid than traditional manufacturing methods. This has made it possible to produce a large amount of merchandise in a short amount of time, which has helped the market grow.

- Numerous investors, including Aviation Capital Ventures PLC, which invests in R&D and business expansion, assist the European aircraft manufacturing industry. The EASA provides funds for R&D to develop and sustain the industry's technological superiority in order to meet industry demand for commercial aircraft. The aviation industry is growing and has an impact on market revenue thanks to consistent capital inflows and solid financial backing.

Aerospace Cold Forgings Market: Restraining factors:

The market for aerospace cold forgings has a few challenges that could slow its expansion. The market may be hampered by a lack of experienced workers and the availability of composite materials with anti-corrosive qualities. However, scientists are working on fresh innovations in the field of cold forging, such as the micro cold forging procedure. The market's development will be facilitated by these research operations, which will produce superior results in the shortest amount of time.

Aerospace Cold Forgings Market – Segmentation

By Type

- Custom Forging

- Captive Forging

- Catalog Forging

By Application

- Airframe

- Landing Gear

- Nacelle Component

Aerospace Cold Forgings Market – Regional Analysis

The aerospace cold forgings market is dominated by North America on a global scale. The emergence of the aerospace sector and the subsequent increase in aircraft production are responsible for the expansion in this area. The market has grown in this region due to growing defense spending as well. Due to the rising demand for commercial aircraft, Asia Pacific is anticipated to increase gradually during the projection period. The expansion of the market in this region has also been facilitated by population increase and technological developments.

Get more details on this report -

Aerospace Cold Forgings Market – Key Market players

- Precision Castparts Corp.

- Eramet, Scot Forge, ATI Metal

- Bharat Forge

- VSMPO-AVISMA Corporation

- Arconic

- Shaanxi Hongyuan Aviation Forging Co., Ltd.

- among others.

Need help to buy this report?