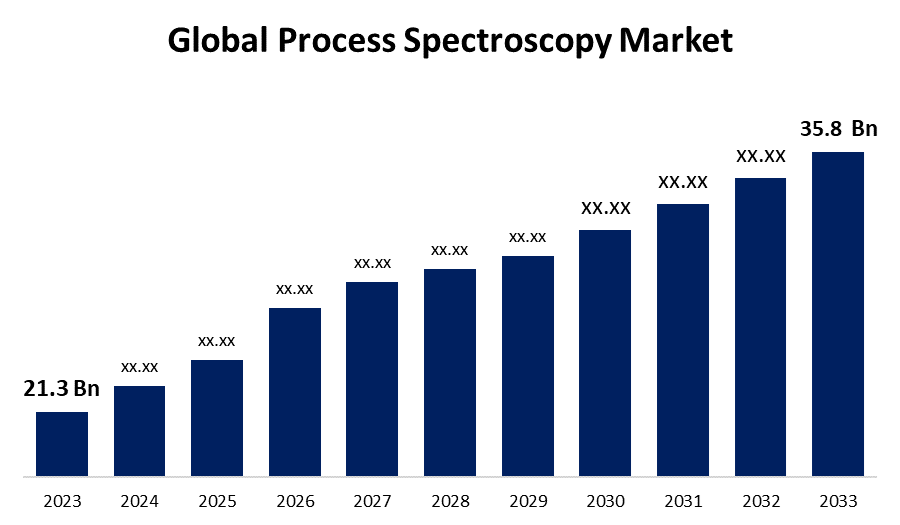

Global Process Spectroscopy Market Size To Worth USD 35.8 Billion By 2033 | CAGR of 5.33%

Category: Aerospace & DefenseGlobal Process Spectroscopy Market Size, To Worth USD 35.8 Billion By 2033

According to a research report published by Spherical Insights & Consulting, the Global Process Spectroscopy Market Size to Grow from USD 21.3 Billion in 2023 to USD 35.8 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 5.33% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 110 Market data tables and figures & charts from the report on the "Global Process Spectroscopy Market Size By Technology (Molecular, Mass), By Application (Pharmaceutical, Food & Beverages), By Region, And Segment Forecasts, By Geographic Scope And Forecast to 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/process-spectroscopy-market

As businesses focus on boosting efficiency and quality control, real-time industrial process monitoring is becoming more and more essential. Process spectroscopy facilitates continuous analysis, which enhances process optimisation and management. Pharmaceutical manufacturing often uses process spectroscopy for real-time monitoring of critical parameters such as medication concentration, purity, and reaction kinetics. It helps to produce consistent, high-quality goods at reduced production costs and with higher productivity. Process spectroscopy is increasingly being connected to automation and digitalization initiatives, such Industry 4.0, in order to facilitate smart production and predictive maintenance. Integration with data analytics and artificial intelligence (AI) enables predictive process control and optimisation.

Process Spectroscopy Market Value Chain Analysis

Suppliers of the basic ingredients, such as chemicals for calibration standards, electronics, detectors, and optical components, required to assemble spectroscopic equipment. Among the parts used in spectroscopic equipment are companies that produce spectrometers, light sources (such as lasers and lamps), detectors (such as CCDs and CMOS sensors), and optical components (such as lenses and mirrors). manufacturers who build whole spectroscopic systems and equipment by integrating calibration standards, software, and hardware into their individual components. companies that specialise in integrating spectroscopic solutions into existing industrial processes or workflows. Through their customisation, installation, and integration services, they ensure the seamless integration of spectroscopic systems into the production environment.

Process Spectroscopy Market Opportunity Analysis

Identify and capitalise on the emerging applications of process spectroscopy in non-traditional sectors such as chemicals and pharmaceuticals. Provide small, lightweight spectroscopic equipment that is portable and useful for field applications, remote monitoring, and point-of-care diagnostics. These technologies can meet the growing demand for on-site analysis, especially in fields like environmental monitoring, agriculture, and food safety. Investigate how to integrate spectroscopic systems with Industry 4.0 and the Internet of Things (IoT) to enhance data analytics, predictive maintenance, and connectivity. Invest in modern data analytics and artificial intelligence (AI) techniques to gain significant insights from spectroscopic data. Using machine learning techniques to improve predictive modelling, anomaly detection, and pattern recognition can lead to more accurate and efficient process control and optimisation.

By using spectroscopic techniques such as near-infrared (NIR) spectroscopy, food and drink samples can be examined quickly and painlessly. Throughout the production process, they allow manufacturers to monitor vital quality indicators such as protein, fat, sugar, freshness, and moisture content in real time. Spectroscopic analysis provides valuable information about the composition and characteristics of raw materials, intermediate products, and finished commodities in the food and beverage preparation process. By employing spectroscopic data, manufacturers can improve yield, optimise processing parameters, and make formula adjustments to minimise waste and production costs. Spectroscopic techniques are useful for identifying allergens, adulterants, and contaminants in food and beverage products. They can help ensure product safety by identifying foreign contaminants, microbial contamination, chemical residues, and hidden substances.

It may be necessary to make a substantial upfront investment in order to buy spectroscopic equipment and implement spectroscopic solutions, particularly for small and medium-sized enterprises (SMEs) or enterprises with restricted finance. High upfront costs can be a barrier to adoption, especially in industries with narrow profit margins. Integrating spectroscopic instruments into existing workflows or manufacturing processes can be challenging and time-consuming. Data management protocols, process interfaces, and legacy systems may not be compatible, requiring extensive knowledge and resources to ensure a seamless integration. Spectroscopic instruments require routine calibration and maintenance in order to function as accurately and efficiently as possible.

Insights by Technology

The molecular segment accounted for the largest market share over the forecast period 2023 to 2033. In several sectors, such as chemicals, food and beverage, and pharmaceuticals, real-time analysis is becoming more and more important. Molecular spectroscopy techniques enable real-time monitoring of critical parameters during industrial operations, enabling rapid and non-destructive inspection of samples. The applications of molecular spectroscopy techniques are incredibly versatile and include molecular structure identification, chemical composition analysis, and quantification of elements in complex combinations. They are suitable for a variety of industries and applications in the process spectroscopy field due to their versatility. Molecular spectroscopy techniques provide real-time input on process parameters, which helps firms improve production processes, enhance productivity, and reduce costs.

Insights by Application

The pharmaceutical segment accounted for the largest market share over the forecast period 2023 to 2033. Process spectroscopy makes it possible to monitor and regulate pharmaceutical manufacturing processes such blending, granulation, drying, milling, and tablet compression in real time. Pharmaceutical companies can use spectroscopic techniques to improve manufacturing processes, reduce variability, and ensure consistency and quality of their products. These techniques provide instantaneous feedback on important process parameters such as moisture content, particle size distribution, and medication content. The advent of lightweight and portable spectroscopic instruments has opened up new avenues for pharmaceutical quality assurance and process monitoring. Thanks to developing technologies that offer on-site analysis, real-time data gathering, and remote monitoring, pharmaceutical enterprises may now monitor manufacturing processes at several stages, from raw material characterization to completed product testing.

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Process Spectroscopy Market from 2023 to 2033. Due to its advanced industrial infrastructure and strong acceptance rates of spectroscopic technology across many industries, North America is a major player in the global process spectroscopy market. North American companies are setting the standard for process spectroscopy technology innovation by developing state-of-the-art spectroscopic tools, software, and integration expertise. The pharmaceutical and biotechnology industries in North America frequently employ process spectroscopy for in-line monitoring of medication manufacturing processes, including blending, granulation, drying, and tablet compression. North America is home to several renowned research institutes and producers, integrators, and service providers of spectroscopic apparatus.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. The market is expanding significantly due to the growing demand for real-time process monitoring, quality control, and optimisation in manufacturing operations across many industries. The Asia-Pacific region has a substantial and diverse industrial base that includes the consumer goods, automotive, electronics, and pharmaceutical industries. These sectors are using spectroscopic technology more often to ensure product quality, reduce expenses, and improve process efficiency. In the Asia-Pacific process spectroscopy market, both domestic and foreign companies offer a wide range of spectroscopic products and services.

Recent Market Developments

- In June 2021, for biotherapeutics, SCIEX unveiled a novel, highly accurate mass LC-MS/MS method.

- In August 2020, Shimadzu Corporation and HORIBA's Raman spectrometers inked a foundational agreement to start working together on the development and marketing of LC-Raman analytical and measurement instruments.

Major players in the market

- ABB, Agilent Technologies, Inc.

- Bruker

- BUCHI

- Danaher

- FOSS

- HORIBA

- Endress+Hauser Group Services AG

- Sartorius AG

- Shimadzu Corporation

- Thermo Fisher Scientific Inc.

- Yokogawa Electric Corporation

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Process Spectroscopy Market, Technology Analysis

- Molecular

- Mass

Process Spectroscopy Market, Application Analysis

- Pharmaceutical

- Food & Beverages

Process Spectroscopy Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- South America

- Brazil

- Argentina

- Colombia

- Middle East & Africa

- UAE

- Saudi Arabia

- South Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?