Global Magnesia Chrome Market Size Worth USD 2.9 Billion By 2033 | CAGR Of 5.49%

Category: Advanced MaterialsGlobal Magnesia Chrome Market Size Worth USD 2.9 Billion By 2033

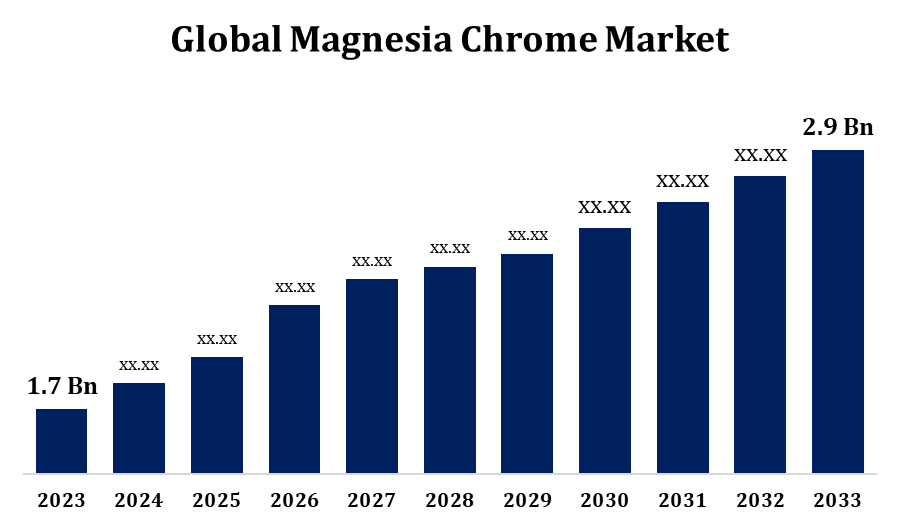

According to a Research Report Published by Spherical Insights & Consulting, The Global Magnesia Chrome Market Size to Grow from USD 1.7 Billion in 2023 to USD 2.9 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 5.49% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 242 pages with 111 Market data tables and figures & charts from the report on the "Global Magnesia Chrome Market Size, Share, and COVID-19 Impact Analysis, By Type (Direct Bonded, Fused/Rebonded, Chemically bonded), By End Use Industry (Iron And Steel, Power Generation, Non-Ferrous metals), and By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2023 – 2033." Get Detailed Report Description Here: https://www.sphericalinsights.com/reports/magnesia-chrome-market

The Magnesia Chrome Market Size is witnessing steady growth, largely fueled by increasing demand from the iron and steel sector, where these bricks are extensively used to line furnaces, kilns, and other high-temperature equipment. Their superior resistance to corrosion, thermal shock, and wear makes them well-suited for demanding industrial conditions. Beyond steel, industries such as cement, glass, and non-ferrous metallurgy are also driving market expansion. The Asia-Pacific region leads global consumption, supported by rapid industrialization and infrastructure development in countries like China and India. However, environmental concerns related to hexavalent chromium emissions have spurred research into alternative formulations and recycling techniques. Leading manufacturers are prioritizing innovation and sustainability to comply with evolving regulations and meet the performance needs of various end-use sectors.

Magnesia Chrome Market Value Chain Analysis

The value chain of the magnesia chrome market size starts with the extraction and processing of key raw materials, mainly magnesite and chromite ores. These are refined to obtain high-purity magnesia and chrome concentrates, which are then fused or sintered to produce magnesia chrome bricks. The manufacturing process includes shaping, firing, and rigorous quality testing to ensure the bricks meet required thermal and mechanical standards. The final products are supplied to industries such as steel, cement, glass, and non-ferrous metal smelting for use in high-temperature furnaces and reactors. Distribution occurs through direct sales to manufacturers as well as third-party suppliers. Proper installation and maintenance downstream are crucial for ensuring durability. Additionally, recycling of used refractories and adoption of environmentally friendly production methods are becoming more prevalent, driven by regulatory and cost-efficiency pressures.

Magnesia Chrome Market Opportunity Analysis

The magnesia chrome market offers strong growth potential, driven by industrial expansion and ongoing infrastructure development, especially in emerging economies across the Asia-Pacific region. Rising demand from the steel, cement, and glass industries continues to boost the need for robust refractory solutions. At the same time, increasing environmental awareness is accelerating the shift toward more sustainable options, including low-chromium and energy-efficient magnesia chrome products. The growing practice of recycling spent refractories not only supports sustainability targets but also delivers cost advantages. Technological innovations, such as automation and digital quality monitoring, are improving product consistency and operational efficiency. Additionally, untapped opportunities in regions like Africa and Latin America offer promising avenues for strategic investment and partnerships, contributing to the market’s long-term expansion.

Rising infrastructure development in emerging economies is poised to drive significant growth in the magnesia chrome brick market. Rapid urbanization and industrialization across regions such as Asia-Pacific, Latin America, and the Middle East are increasing the demand for high-performance refractory materials in construction-related sectors like steel, cement, and glass. Valued for their durability, corrosion resistance, and thermal stability, magnesia chrome bricks are essential for lining high-temperature equipment such as furnaces, kilns, and reactors. As governments continue to invest in large-scale projects including roads, power plants, bridges, and manufacturing hubs, the need for these refractory materials is set to rise. Furthermore, a growing focus on energy efficiency and sustainable building practices is pushing manufacturers to develop innovative products that meet evolving environmental and performance requirements.

The magnesia chrome brick market faces several significant challenges. One of the primary concerns is the stringent environmental and health regulations surrounding hexavalent chromium emissions during both production and disposal, which raise compliance costs for manufacturers. Fluctuating prices of raw materials like magnesite and chromite often impacted by geopolitical tensions and supply chain disruptions add further pressure to profitability and market planning. The market’s strong dependence on the iron and steel industry, its largest consumer, makes it susceptible to shifts in steel production cycles. Additionally, the increasing adoption of alternative refractory materials, such as alumina- and silica-based bricks, which are often more cost-effective and environmentally friendly, is heightening competition. Compounding these challenges is the limited regional availability of magnesite and reliance on imports, especially from China, which threatens long-term supply stability.

Insights by Type

The Direct Bonded segment accounted for the largest market share over the forecast period 2023 to 2033. The direct bonded magnesia chrome brick segment is experiencing robust growth worldwide, driven by increasing demand from major industries such as iron and steel, cement, and glass. These bricks are highly valued for their superior thermal stability, corrosion resistance, and mechanical strength, making them ideal for lining high-temperature equipment like furnaces, kilns, and reactors. Expanding industrial activity and ongoing infrastructure development, particularly in steel production, are key factors fueling this upward trend. Additionally, advancements in manufacturing processes and a rising focus on sustainability are prompting the development of more environmentally friendly solutions within the segment. With continued technological innovation and expanding applications across various high-temperature industrial sectors, the direct bonded magnesia chrome brick market is poised for sustained growth.

Insights by End Use

The iron and steel segment accounted for the largest market share over the forecast period 2023 to 2033. Growth in the iron and steel segment of the magnesia chrome brick market is being propelled by expanding infrastructure projects and increasing demand for consumer goods, which heighten the need for durable refractory materials. Rapid industrialization and urbanization particularly in Asia-Pacific are further fueling this momentum. Technological advancements and improvements in manufacturing processes are also contributing by enhancing the performance and efficiency of these bricks. While environmental regulations pose certain challenges, the consistent need for dependable high-temperature linings in steel production continues to drive steady growth in this segment.

Insights by Region

Get more details on this report -

North America is anticipated to dominate the Magnesia Chrome Market from 2023 to 2033. The magnesia chrome brick market in North America remains stable, driven by the strength of the iron and steel and cement industries. The United States leads regional consumption, fueled by the continuous demand for reliable, high-temperature linings in steel production. In Canada, ongoing infrastructure development is increasing the need for refractory materials in cement manufacturing and other heat-intensive operations. Mexico’s expanding industrial landscape also contributes to market growth. Moreover, rising investments in renewable energy projects such as waste-to-energy plants and thermal power facilities are further supporting demand for magnesia chrome bricks in applications like boilers and reactors. Technological advancements and a growing emphasis on sustainability are encouraging the use of cleaner, high-performance refractory solutions. Although growth in North America is more moderate than in Asia-Pacific, steady investment across key sectors is expected to sustain long-term market development.

Asia Pacific is witnessing the fastest market growth between 2023 to 2033. The iron and steel industry remains the leading consumer of magnesia chrome bricks in the Asia-Pacific region, utilizing them extensively to line furnaces and vessels exposed to extreme temperatures. Growing demand from sectors such as power generation, cement, and glass is further driving the need for high-performance refractory materials. Large-scale infrastructure projects and rapid urbanization across the region continue to fuel market expansion. However, the industry faces challenges, including environmental concerns over chromium emissions and variability in raw material supply. In response, major manufacturers are prioritizing the development of sustainable and cost-effective solutions that comply with stringent regulations while maintaining performance standards. These efforts are supporting ongoing growth and technological innovation in the Asia-Pacific magnesia chrome brick market.

Recent Market Developments

- In January 2020, RHI Magnesita acquired Missouri Refractories Co., Inc. (MORCO) to strengthen its footprint in the North American refractory market. The acquisition supports RHI Magnesita’s strategic objectives, with MORCO’s operations aligning closely with the company’s regional growth plans and reinforcing its market position.

Major players in the market

- Magnezit Group

- Mayerton

- Minerex India

- Qinghua Refractories co. Ltd

- Resco Products

- Calderys

- Chosun Refractories Co. Ltd

- Gita Refractories

- Harbisonwalker International

- KT Refractories

Market Segmentation

This study forecasts revenue at global, regional, and country levels from 2023 to 2033.

Magnesia Chrome Market, Type Analysis

- Direct Bonded

- Fused/Rebonded

- Chemically bonded

Magnesia Chrome Market, End Use Industry Analysis

- Iron And Steel

- Power Generation

- Non-Ferrous metals

Magnesia Chrome Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of the Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?