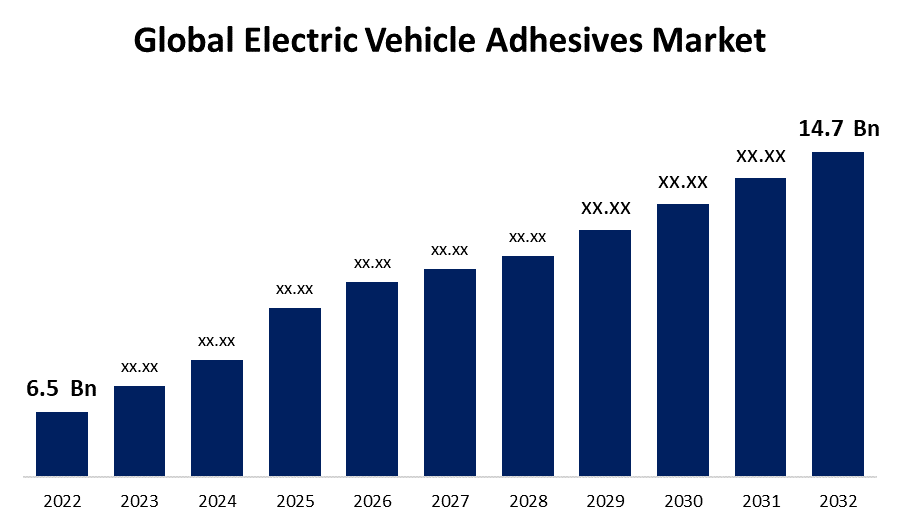

Global Electric Vehicle Adhesives Market Size To Worth USD 14.7 Billion By 2032 | CAGR of 48.1%

Category: Chemicals & MaterialsGlobal Electric Vehicle Adhesives Market Size To Worth USD 14.7 Billion By 2032.

According to a research report published by Spherical Insights & Consulting, the Global Electric Vehicles Adhesives Market Size to grow from USD 6.5 Billion in 2022 to USD 14.7 Billion By 2032, at a Compound Annual Growth Rate CAGR of 48.1% during the forecast period.

Get more details on this report -

Browse key industry insights spread across 200 pages with 120 Market data tables and figures & charts from the report on, the Global Electric Vehicle Adhesives Market Size, Share, and COVID-19 Impact, By Resin Type (Epoxy, Acrylic, Silicone, Polyurethane), By Form Type (Film & Tape, Liquid), By Vehicle Type (Battery Electric Vehicle, Plug-In Hybrid Electric Vehicle), By Application (Pack & Module Bonding, Battery Cell Encapsulation, Thermal Interface Bonding), By Region (North America, Europe, Asia-Pacific, Latin America, Middle East, and Africa), Analysis and Forecast 2022 – 2032." Get Detailed Report Description Here:https://www.sphericalinsights.com/reports/electric-vehicle-adhesives-market

Electric vehicle adhesives are necessary for the development, assembly, and building of EVs. Because electric cars (EVs) differ from traditional internal combustion engine vehicles in terms of their characteristics and requirements, specialised adhesives are necessary to ensure the structural integrity, safety, and performance of EVs. These adhesives are designed to provide a strong bond between the various metals, composite materials, and polymers utilised in the production of electric vehicles. They are used to join the battery pack, chassis, and body panels, among other structural components and parts. Structural adhesives increase the overall stiffness and strength of the vehicle while reducing weight and the need for traditional welding methods.

COVID 19 Impact

The pandemic disrupted global supply chains, which had an effect on the availability of the raw materials and components required to create the adhesives for electric vehicles. Many countries imposed lockdowns and travel restrictions, which resulted in factory closures and logistical challenges. Some glue producers struggled to find the raw materials they need and to market their products as a result. Many EV manufacturers were forced to temporarily suspend production during the shutdown in order to protect their staff. The manufacturing slowdown and decrease in production capacity hindered the market for adhesives for electric vehicles.

The global market for electric vehicles adhesives was rapidly growing as a result of growing environmental consciousness, government incentives, and advancements in EV technology. As demand for electric vehicles increased, so did the need for the specialised adhesives used in their production and assembly. The upshot of continued research and development activities in the adhesive industry is the creation of adhesives with improved properties, such as increased temperature resistance, more sturdiness, and improved electrical conductivity. These innovations dealt specifically with the needs of electric vehicles. In response to the market's potential for growth in the electric car industry, numerous adhesive manufacturers and suppliers have invested in R&D and capacity expansion.

Electric automobiles can run in a wide range of temperatures, from extremely cold to intense heat generated when driving. Adhesives used in electric vehicles (EVs) must maintain their properties and performance under these diverse conditions. Ensuring the vehicle's long-term resistance to environmental factors like humidity, wetness, and chemical exposure is essential for its durability and safety. For electric cars to operate more efficiently and cover greater distances, weight reduction is a top aim. As a result, diverse lightweight materials including composites, aluminium, and high-strength steel must be successfully attached using adhesives. It can be challenging to ensure the coherence and long-term adherence of these materials.

Resin Type Insights

Polyurethane segment is dominating the market over the forecast period

On the basis of resin type, the global electric vehicle adhesives market is segmented into epoxy, acrylic, silicone, polyurethane, and others. Among these, polyurethane segment is dominating the market with the largest market share over the forecast period. To enhance the formulations of polyurethane adhesives created expressly for use in applications for electric cars, manufacturers are investing in R&D. Better adhesives have been created as a result to satisfy the shifting demands of the electric vehicle industry. Polyurethane adhesives are lighter than certain common joining methods like welding or mechanical fastening. As electric vehicles focus on reducing weight to enhance energy efficiency and range, the use of lightweight adhesives is become increasingly enticing.

Form Type Insights

Liquid segment accounted the largest market share over the forecast period

Based on the form type, the global electric vehicle adhesives market is segmented into film & tape, liquid, and others. Among these, the liquid segment accounted the largest market share over the forecast period. In electric vehicles, a range of methods, like as brushing, spraying, and dispensing, can be used to easily and precisely apply liquid adhesives to various surfaces and components. The composition of liquid adhesives can include various curing techniques, such as moisture curing or heat curing, permitting a variety of curing speeds to meet various assembly requirements and production demands. For usage with electric car battery applications, the capacity to create liquid adhesives that adhere while meeting safety standards and possessing properties that make them fire-resistant is crucial.

Vehicle Type Insights

Plug-In Hybrid Electric Vehicle segment is dominating the market over the forecast period

On the basis of vehicle type, the global electric vehicle adhesives market is segmented into battery Electric Vehicles and plug-in hybrid Electric Vehicles. Among these, plug-in hybrid electric vehicle segment is dominating the market over the forecast period. PHEVs require robust adhesive solutions for the battery pack, which includes both conventional lead-acid batteries and cutting-edge lithium-ion batteries. Under a range of operating conditions, adhesives are necessary to preserve the stability and security of the battery pack. The dual powertrain design of PHEVs creates unique cost challenges. The makers of PHEVs look for adhesives that strike a compromise between cost-effectiveness and performance.

Application Insights

Pack and module bonding segment holds the highest market share

Based on the application, the global electric vehicle adhesives market is segmented into pack & module bonding, battery cell encapsulation, thermal interface bonding, and others. Among these, pack and module segment holds the highest market share over the forecast period. Significant advancements in battery technology for electric vehicles have led to the development of high-energy-density battery cells and modules. Adhesives are used to bond and seal these cutting-edge battery parts, ensuring their dependable operation and security. Adhesive solutions that make it easier to recycle battery materials and parts are vital, in keeping with the automotive industry's push for the circular economy principles.

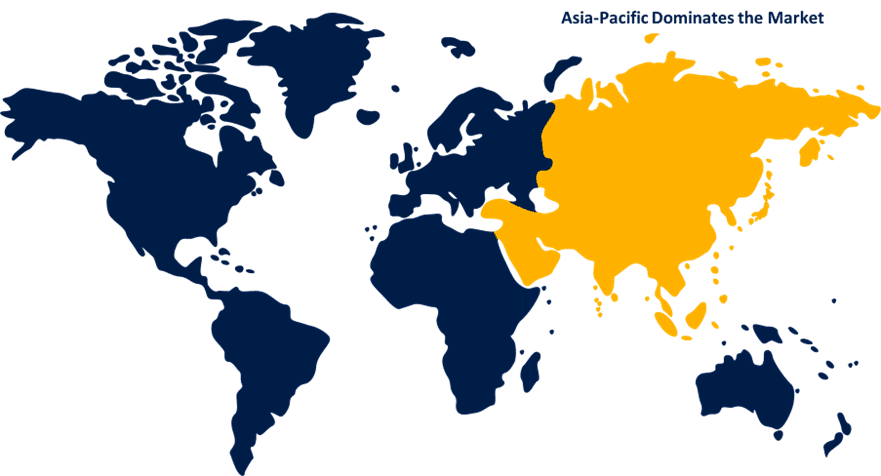

Regional Insights

Asia Pacific is dominating the market over the forecast period.

Get more details on this report -

Asia Pacific region is dominating the market with the largest market share over the forecast period. Asia Pacific is a key hub for the production of batteries because countries like China, South Korea, and Japan are significant players in the world battery market. Assembling batteries calls for specialised adhesives, which increases the market's need for adhesives for electric vehicles. Leading automakers are investing heavily in the development and manufacturing of electric vehicles in the Asia Pacific region. As a result of this surge in electric car production, the market for adhesives for electric vehicles has grown.

North America is witnessing the fastest market growth over the forecast period. North American automakers and technology companies continuously concentrate their research and development efforts on the advancement of electric vehicle technologies. As battery technologies and EV components advance, there is an increasing need for high-tech adhesives to support these developments. Due to the expansion of the infrastructure for charging them in North America, which has increased consumer interest in and demand for them, the convenience and viability of owning an electric automobile have improved.

Market Segment

This study forecasts revenue at global, regional, and country levels from 2019 to 2032. Spherical Insights has segmented the global Electric Vehicle Adhesives Market based on the below-mentioned segments:

Electric Vehicle Adhesives Market, Resin Type Analysis

- Epoxy

- Acrylic

- Silicone

- Polyurethane

- Others

Electric Vehicle Adhesives Market, Form Type Analysis

- Film & tape

- Liquid

- Others

Electric Vehicle Adhesives Market, Vehicle Type Analysis

- Battery Electric Vehicles

- Plug-in hybrid Electric Vehicles

Electric Vehicle Adhesives Market, Application Analysis

- Pack & module bonding

- Battery cell encapsulation

- Thermal interface bonding

- Others

Electric Vehicle Adhesives Market, Regional Analysis

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- Uk

- France

- Italy

- Spain

- Russia

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Rest of Asia Pacific

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- UAE

- Saudi Arabia

- Qatar

- South Africa

- Rest of Middle East & Africa

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?