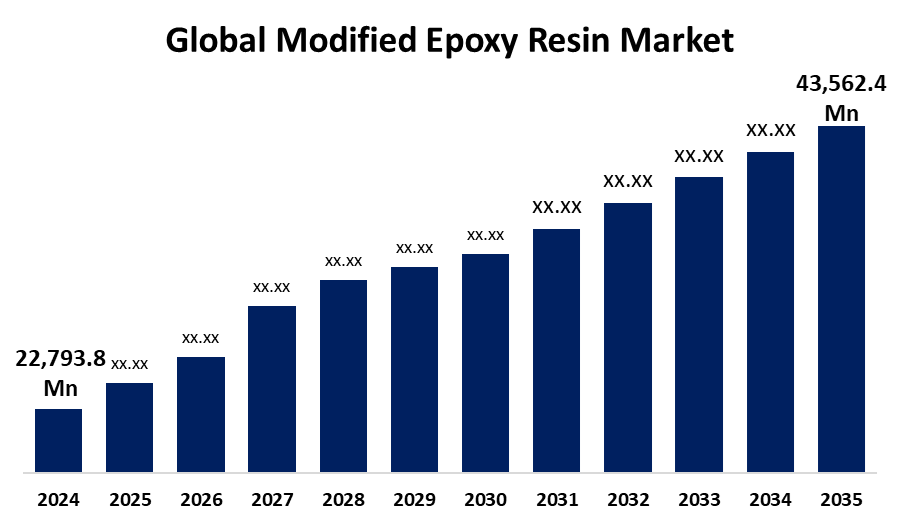

Global Modified Epoxy Resin Market Insights Forecasts to 2035

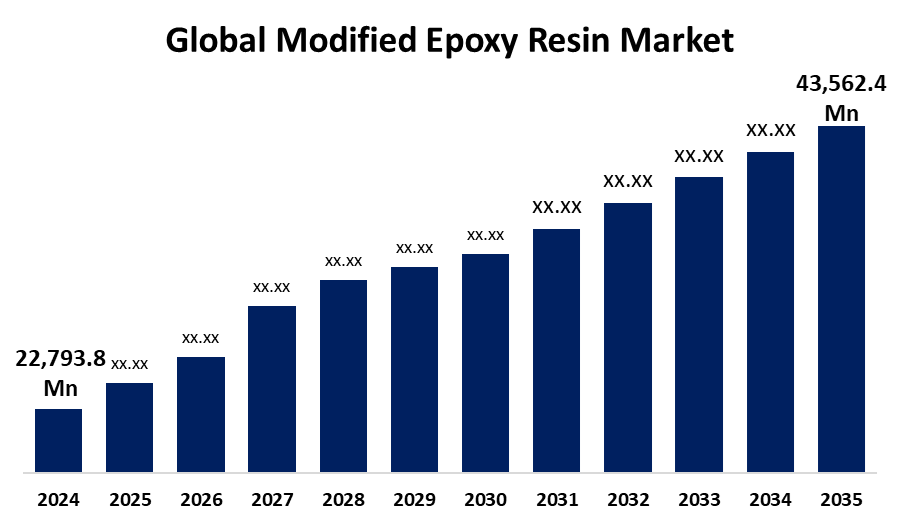

- The Global Modified Epoxy Resin Market Size Was Estimated at USD 22,793.8 Million in 2024

- The Market Size is Expected to Grow at a CAGR of around 6.07% from 2025 to 2035

- The Worldwide Modified Epoxy Resin Market Size is Expected to Reach USD 43,562.4 Million by 2035

- North America is Expected to Grow the fastest during the forecast period.

Modified Epoxy Resin Market

The global modified epoxy resin market is defined by the growing adoption of these resins in a variety of industries, including automotive, construction, electronics, and coatings. Modified epoxy resins are engineered to provide enhanced properties such as increased flexibility, improved heat resistance, stronger adhesion, and better chemical resistance compared to standard epoxy resins. These advantages make them ideal for applications such as adhesives, paints, coatings, electrical components, and composite materials. The resins are valued for their durability, versatility, and performance, which contribute to their widespread use in high-performance products. As industries continue to demand materials that offer both strength and sustainability, modified epoxy resins are becoming increasingly important in advanced manufacturing processes. Innovations in resin formulations and production techniques further boost their utility, allowing them to meet the specific needs of various applications, thereby enhancing the market's overall potential and competitiveness.

Attractive Opportunities in the Modified Epoxy Resin Market

- Rapid industrialization in regions like Asia-Pacific offers significant growth potential, driven by rising demand for modified epoxy resins in sectors such as construction, automotive, and electronics.

- Increasing demand for high-performance materials in the renewable energy sector, particularly for wind turbine blades and solar panels, creates opportunities for modified epoxy resins with superior durability and weather resistance.

- Growing demand for eco-friendly and bio-based resins driven by sustainability trends in industries like construction and automotive. Companies can capitalize on producing environmentally responsible resins.

Global Modified Epoxy Resin Market Dynamics

DRIVER: Increasing need for high-performance, durable materials across various industrial sectors

The global modified epoxy resin market is experiencing robust growth, fueled by the increasing need for high-performance, durable materials across various industrial sectors. As industries such as automotive, aerospace, and electronics demand more specialized solutions, modified epoxy resins have emerged as a key material due to their superior properties, including enhanced flexibility, heat resistance, and chemical stability. These resins are pivotal in applications ranging from adhesives and coatings to composites and electrical components, where reliability and performance are crucial. The push for lightweight materials, particularly in automotive manufacturing to improve fuel efficiency, is another strong driver. Furthermore, the growing emphasis on sustainability is prompting the development of eco-friendly resin formulations, further accelerating market growth. As industries seek to meet the evolving demands for high-strength, energy-efficient, and environmentally responsible materials, the market for modified epoxy resins continues to expand with innovative solutions.

RESTRAINT: Fluctuating prices of raw materials, particularly the chemicals used in resin production

While the global modified epoxy resin market continues to expand, it faces several challenges that may hinder its growth. A key restraint is the fluctuating prices of raw materials, particularly the chemicals used in resin production. This unpredictability can lead to increased costs for manufacturers, which in turn affects the pricing structure of the final product. Moreover, the production of modified epoxy resins often involves complex and costly processes, requiring specialized equipment and expertise, which can limit market accessibility for smaller players. Environmental concerns also pose a significant challenge, as the production and disposal of certain resins may involve the release of volatile organic compounds (VOCs) and other harmful substances, prompting stricter regulations and sustainability demands. Additionally, competition from alternative materials like polyurethanes or polyesters, which offer comparable performance at potentially lower costs, adds pressure to the market. These factors collectively hinder the broader adoption and growth of modified epoxy resins across industries.

OPPORTUNITY: Development of new resin formulations tailored to specific niche applications

One significant opportunity lies in the development of new resin formulations tailored to specific niche applications, such as high-temperature or corrosion-resistant coatings for industrial machinery and marine environments. Innovations in bio-based or sustainable resins offer potential for companies looking to capitalize on the growing demand for environmentally friendly materials. Additionally, the rise of 3D printing technology has opened up new avenues for using modified epoxy resins in additive manufacturing, particularly in custom-designed parts for aerospace and automotive industries. There is also an expanding market for modified epoxy resins in renewable energy sectors, such as wind turbine blades and solar panels, where lightweight, durable materials are in high demand. The increasing interest in electric vehicles (EVs) further presents opportunities, as lightweight composites and advanced coatings become integral to EV manufacturing. These emerging sectors provide fertile ground for growth and innovation.

CHALLENGES: The complexity of achieving a balance between performance and cost-efficiency

One such issue is the complexity of achieving a balance between performance and cost-efficiency. As industries demand increasingly specialized resins for specific applications, manufacturers face difficulties in tailoring formulations that deliver both exceptional properties and remain cost-effective. Additionally, scaling up production of high-performance resins while maintaining quality consistency can be challenging, particularly for smaller manufacturers. Another challenge is the integration of modified epoxy resins into emerging technologies like smart coatings or nanocomposites, where the technical demands for precision and customization are higher. The market also faces a gap in standardization, with different industries often requiring varying resin specifications, making mass adoption and uniformity in production difficult. Lastly, the slow pace of regulatory approvals for new resin formulations can delay product launches, preventing companies from capitalizing on emerging market opportunities promptly.

Global Modified Epoxy Resin Market Ecosystem Analysis

The global modified epoxy resin market ecosystem consists of raw material suppliers, resin manufacturers, end-user industries, distributors, and regulatory bodies. Raw material suppliers provide key components like epichlorohydrin and bisphenol-A. Resin manufacturers develop high-performance formulations, driven by industry-specific demands. End-users, including automotive, construction, and electronics sectors, drive the need for durable materials. Distributors connect manufacturers with users, while regulatory authorities enforce sustainability and safety standards. Research institutions contribute through innovations in resin technology. Together, these components foster market growth through collaboration and continuous advancement.

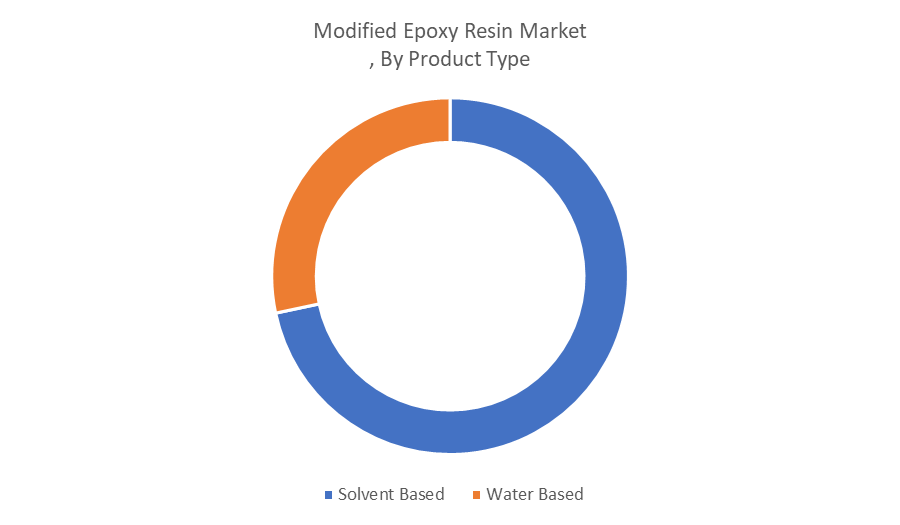

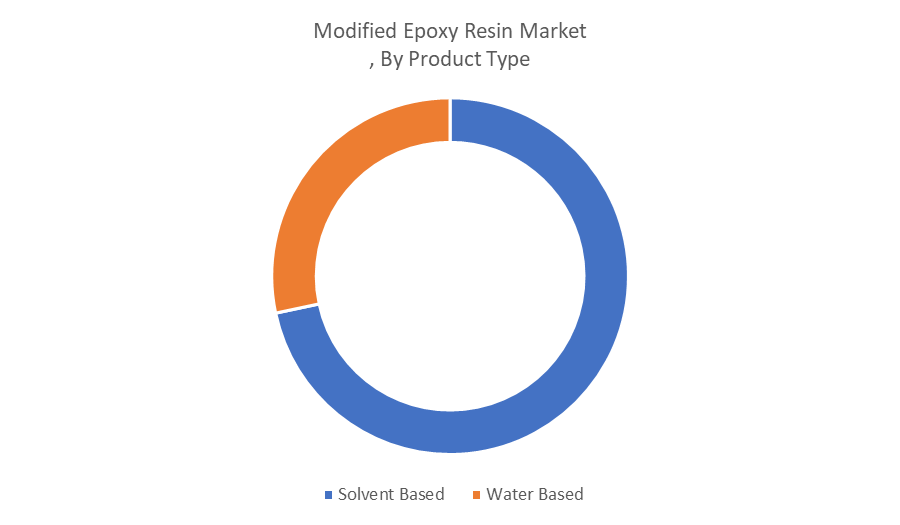

Based on the product type, the solvent-based segment held the largest revenue share and is expected to grow at a substantial CAGR over the forecast period

Solvent-based resins offer advantages such as enhanced adhesion, improved finish, and superior durability, making them ideal for industries like automotive, construction, and industrial coatings. These resins are particularly favored for their versatility in a variety of environmental conditions. The segment is expected to grow at a substantial compound annual growth rate (CAGR) during the forecast period, driven by increasing demand for efficient and long-lasting coatings, as well as advancements in solvent-based formulations that meet stricter environmental regulations. As industries continue to seek durable, high-performance solutions, the solvent-based modified epoxy resins will remain a dominant choice in the market.

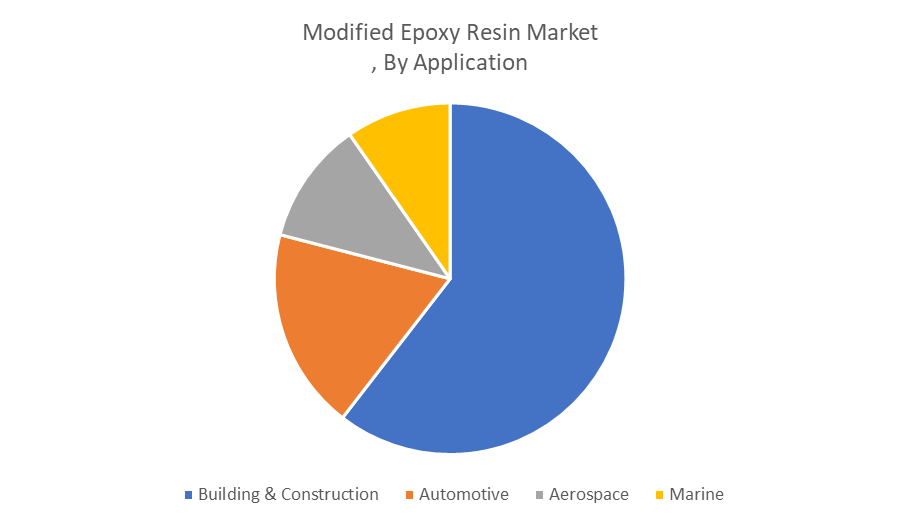

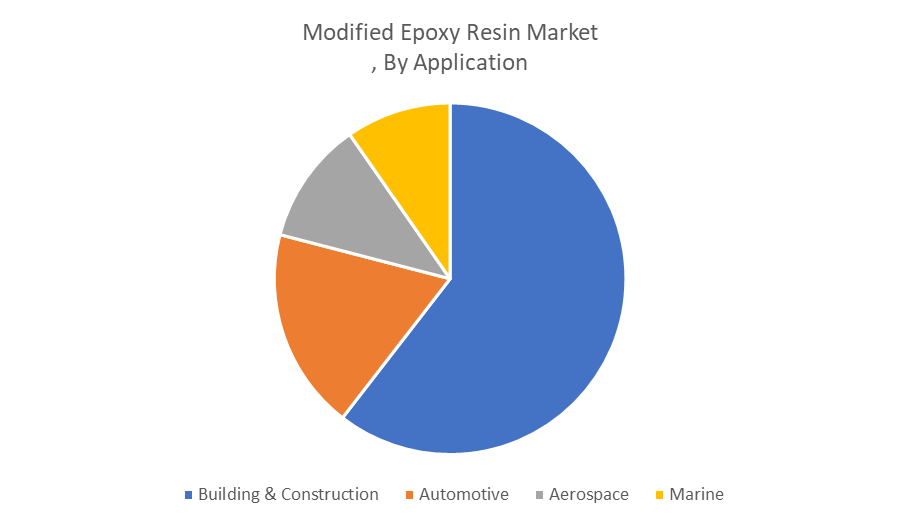

Based on the application, the building & construction held the largest revenue share during the forecast period

The segment growth is primarily due to the high demand for durable, long-lasting materials that can withstand harsh environmental conditions and provide superior adhesion and chemical resistance. Modified epoxy resins are widely used in flooring, concrete coatings, adhesives, sealants, and protective coatings for both residential and commercial buildings. As infrastructure development and construction projects continue to rise globally, the demand for these high-performance resins is expected to grow significantly. Furthermore, the increasing emphasis on energy-efficient, eco-friendly, and sustainable building practices is further boosting the adoption of modified epoxy resins in the construction industry. The sector's continued expansion and the ongoing need for high-quality, protective coatings will drive substantial growth for the building and construction application segment throughout the forecast period.

Asia Pacific is anticipated to hold the largest share of the modified epoxy resin market during the forecast period

Asia Pacific is anticipated to hold the largest share of the modified epoxy resin market during the forecast period, driven by rapid industrialization, urbanization, and significant demand from key sectors such as automotive, construction, and electronics. The region's booming infrastructure development and growing manufacturing capabilities are major factors fueling the demand for high-performance resins in coatings, adhesives, and composite materials. Additionally, countries like China, India, and Japan are major producers and consumers of modified epoxy resins, benefiting from a large industrial base and rising investment in renewable energy and automotive industries. The region also sees increasing adoption of eco-friendly materials and advanced manufacturing processes, which further boosts the market growth. With ongoing infrastructure projects and a thriving industrial sector, Asia Pacific is set to continue dominating the global market, supported by both domestic and export demand for modified epoxy resins.

North America is expected to grow at a significant CAGR in the modified epoxy resin market during the forecast period

North America is expected to grow at a significant CAGR in the modified epoxy resin market during the forecast period. This growth is driven by strong demand across key industries, including automotive, aerospace, construction, and electronics. The increasing focus on advanced manufacturing technologies, such as lightweight composites for electric vehicles (EVs) and durable coatings for infrastructure projects, is further propelling the use of modified epoxy resins. Additionally, the region's stringent environmental regulations are pushing for the development of more sustainable and high-performance resin formulations. North America’s robust research and development efforts, along with the presence of major resin manufacturers, are expected to drive innovation and product differentiation, enhancing the market's growth potential. The rising trend of renewable energy installations, particularly in wind and solar industries, also presents new opportunities for the adoption of modified epoxy resins, supporting further market expansion in the region.

Recent Development

- In January 2023, Momentive launched a new high-performance epoxy resin aimed at the electronics industry. This resin enhances electrical insulation properties and is optimized for use in semiconductors and consumer electronics applications that require precise electrical conductivity and thermal stability.

Key Market Players

KEY PLAYERS IN THE MODIFIED EPOXY RESIN MARKET INCLUDE

This study forecasts revenue at global, regional, and country levels from 2020 to 2035. Spherical Insights has segmented the modified epoxy resin market based on the below-mentioned segments: