World’s Top 70 Companies in Epoxy Tooling Board Market in 2025 Watchlist: Statistical Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

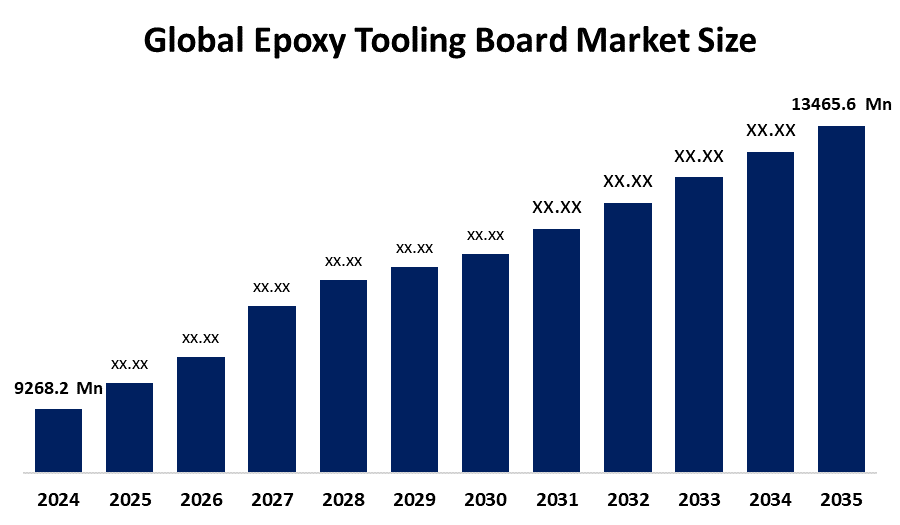

According to a research report published by Spherical Insights & Consulting, The Global Epoxy Tooling Board Market Size is projected To Grow from USD 9268.2 Million in 2024 to USD 13465.6 Million by 2035, at a CAGR of 3.45% during the forecast period 2025–2035. The epoxy tooling board market is expanding due to increased demand in the aerospace, automotive, and marine industries, which is fuelled by its durability, lightweight qualities, ease of machining, and suitability for high-temperature applications.

Introduction

The Epoxy Tooling Board Market Size is a stiff, high-density board constructed of epoxy resin that is used to make long-lasting moulds, patterns, and prototypes. It has high dimensional stability, machinability, and resistance to heat and chemicals, making it perfect for use in industries like as aerospace, automotive, and marine where precision and performance are critical. The market for epoxy tooling boards is expanding steadily because of its exceptional qualities, which include high compression strength, minimal thermal expansion, better surface polish, and heat and thermal resistance. Because of their accuracy and robustness, epoxy tooling boards are widely utilised in the automotive, marine, and aerospace industries for mould fabrication and prototyping. The factors driving expansion are the growing usage of epoxy resins in the construction of wind turbine blades and the need for efficient, reasonably priced manufacturing solutions. The boards' attractiveness in creating sophisticated moulds and composite parts is further enhanced by their capacity to reduce autoclave curing periods. Epoxy formulation innovations keep enhancing surface quality and dimensional stability. As sectors embrace advanced methods like automation and additive manufacturing, opportunities are growing. Advanced epoxy composites are being developed through partnerships with research universities. Eco-friendly tooling solutions are being influenced by sustainability trends, while product development is being accelerated by digital design and simulation tools, which enable greater production precision and a quicker time to market.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Epoxy Tooling Board Market.

Epoxy Tooling Board Market Size & Statistics

- The Market Size for Epoxy Tooling Board Was Estimated to be worth USD 9268.2 Million in 2024.

- The Market Size is Going to Expand at a CAGR of 3.45% between 2025 and 2035.

- The Global Epoxy Tooling Board Market Size is anticipated to reach USD 13465.6 Million by 2035.

- North America is expected to generate the highest demand during the forecast period in the Epoxy Tooling Board Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Epoxy Tooling Board Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the epoxy tooling board market. The market for epoxy tooling boards is anticipated to grow at the fastest rate in the Asia Pacific due to the region's fast industrialisation, growing automotive and electronics manufacturing industries, and rising need for high-performance, reasonably priced materials. Asia Pacific will be a major player in the worldwide epoxy tooling board market during the projected period due to the region's robust industrial base, encouraging government efforts, and growing infrastructure and technology expenditures.

North America is expected to generate the highest demand during the forecast period in the epoxy tooling board market. The region's emphasis on contemporary manufacturing technology has led to a significant demand for quick prototyping. North America holds the largest market share for epoxy tooling boards. The industrial sectors in the US and Canada are well-established, especially in the automobile and aerospace sectors. Epoxy boards have gained a sizable market share in this area due to the rising demand for premium tooling solutions.

Top 10 trends in the Epoxy Tooling Board Market

- Rising Demand from Aerospace & Automotive Industries

- Increased Use in Wind Energy

- Advancements in Epoxy Resin Formulations

- Adoption of Additive Manufacturing & 3D Printing

- Focus on Lightweight & High-Strength Materials

- Growing Demand for Rapid Prototyping Solutions

- Shift Toward Sustainable & Eco-Friendly Materials

- Automation & Digital Design Integration (CAD/CAM)

- Reduction in Autoclave Curing Time

- Collaborations Between Manufacturers & Research Institutions

1. Rising Demand from Aerospace & Automotive Industries

These industries require high-precision, heat-resistant tooling materials. Epoxy tooling boards offer strength, dimensional stability, and machinability, making them ideal for creating molds, prototypes, and components. Their increasing use in lightweight, complex part manufacturing is fueling market growth.

2. Increased Use in Wind Energy

Large wind turbine blade moulds are being made using epoxy tooling boards as a result of the increased focus on renewable energy around the world. The high-performance requirements of wind energy components are supported by their superior surface quality, structural integrity, and thermal resistance.

3. Advancements in Epoxy Resin Formulations

Boards with enhanced durability, heat resistance, and dimensional correctness are being produced because of advancements in epoxy chemistry. Better surface finishes and longer mould lifespans made possible by improved formulations draw in industries that require high-performance and reasonably priced tooling materials.

4. Adoption of Additive Manufacturing & 3D Printing

Users of tooling boards are increasingly incorporating 3D printing to swiftly construct intricate shapes. Prototyping cycles are sped up and material waste is decreased, while epoxy boards' machinability and compatibility with hybrid manufacturing techniques enhance additive processes.

5. Focus on Lightweight & High-Strength Materials

Industries are demanding materials that offer both low weight and high structural strength. Epoxy tooling boards meet these needs, making them suitable for parts that require high performance without increasing the weight of the finished product.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the epoxy tooling board market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 14 Companies Leading the Epoxy Tooling Board Market

- Huntsman Corporation

- Axson Technologies

- Trelleborg AB

- General Plastics Manufacturing Company

- RAMPF Group Inc

- Base Group

- Alro Plastics

- Coastal Enterprises Inc

- Demacq Recycling Company.

- Sikaaxson

- BCC Products Inc.

- Stevik

- Guangzhou LiHong Mould Material Co., Ltd

- Curbell Plastics Inc.

- Others

1. Huntsman Corporation

Headquarters: The Woodlands, Texas, USA

Huntsman Corporation was established in 1970 and is a world leader in speciality chemicals, catering to sectors like energy, electronics, construction, automotive, and aerospace. The three primary business segments of the corporation are Advanced Materials, Performance Products, and Polyurethanes. With its cutting-edge epoxy systems, adhesives, and composite materials, Huntsman is well-known for supporting high-performance applications in a variety of industries. The company employs about 7,000 consumers and has more than 60 manufacturing and research, and development sites spread across more than 25 countries. Huntsman is dedicated to sustainability, innovation, and long-term value development through science-driven solutions. The company is listed on the New York Stock Exchange under the ticker code HUN.

2. Axson Technologies

Headquarters: Paris, France

Axson Technologies specializes in high-performance epoxy and polyurethane resins for tooling, prototyping, composites, and encapsulating applications. The company runs six production facilities in the USA, Mexico, France, Slovakia, China, and Japan, catering to sectors like automotive, aerospace, marine, renewable energy, and construction. Sika AG, a world leader in speciality chemicals, purchased Axson Technologies in 2015, expanding its product line in the tools and composites industry. Design, prototyping, and production processes are supported by Axson's creative solutions, which enhance a range of industrial applications.

3. Trelleborg AB

Headquarters: Trelleborg, Sweden

Trelleborg AB is a multinational engineering firm with a focus on polymer technologies that was founded in 1905. For harsh industrial settings, the business creates and produces cutting-edge sealing, damping, and protecting solutions. Trelleborg is divided into five companies: Trelleborg Wheel Systems, Trelleborg Coated Systems, Trelleborg Medical Solutions, Trelleborg Sealing Solutions, and Trelleborg Industrial Solutions. Trelleborg serves sectors like aerospace, automotive, construction, and energy and has more than 100 manufacturing plants across the globe, employing about 15,646 people. The company, which is dedicated to sustainability and technical advancement, is listed on the Nasdaq Stockholm under the ticker symbol TREL B.

4. General Plastics Manufacturing Company

Headquarters: Tacoma, Washington, USA

General Plastics Manufacturing Company was established in 1941 and is a manufacturer of high-performance rigid and flexible polyurethane foams, such as its proprietary LAST-A-FOAM® series. In order to serve industries including aerospace, defence, marine, and energy, the company provides build-to-print assemblies, composite laminates, and custom cast parts. General Plastics is a 135,000-square-foot company with more than 170 specialists and an ISO 9001:2015/AS9100D certification located in Tacoma, Washington. The business serves customers all over the world through a network of distributors and is renowned for its dedication to quality and innovation. General Plastics, a privately held company, is still at the forefront of producing sophisticated composites.

5. RAMPF Group Inc

Headquarters: Wixom, Michigan, USA

RAMPF Group, Inc. is a division of Germany-based RAMPF Holding GmbH & Co. KG. Serving the automotive, aerospace, marine, and energy sectors, the company specialises in high-performance reactive resin systems, such as polyurethane, epoxy, and silicone-based compounds. Under the RAKU® trademark, RAMPF provides a wide range of goods, such as modelling and tooling boards, sealing foams, electro casting resins, and adhesives. For accurate reactive resin processing, the company also offers automated mixing and dispensing equipment. With cutting-edge facilities in Suwanee, Georgia, and Wixom, Michigan, RAMPF Group, Inc. is dedicated to providing creative solutions that satisfy the changing demands of its international customers.

Are you ready to discover more about the Epoxy Tooling Board market?

The report provides an in-depth analysis of the leading companies operating in the global epoxy tooling board market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes

Company Profiles

- Huntsman Corporation

Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Axson Technologies

- Trelleborg AB

- General Plastics Manufacturing Company

- RAMPF Group Inc

- Base Group

- Alro Plastics

- Coastal Enterprises Inc

- Demacq Recycling Company.

- Sikaaxson

- BCC Products Inc.

- Stevik

- Guangzhou LiHong Mould Material Co., Ltd

- Curbell Plastics Inc.

- Others

Conclusion

Technological developments and growing applications in the consumer goods, electronics, and automotive industries are expected to propel the worldwide epoxy tooling board market's steady rise. Production precision and operational flexibility are increased by improved designs, robust materials, and automation. Notwithstanding obstacles such as high production costs and pressure from competitors, market expansion is driven by growing demand in manufacturing sectors. The importance of epoxy tooling boards in contemporary precision production across the globe is cemented by ongoing research and development, quality enhancements, and purposeful international expansion.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?