World’s Top 65 Sprue Bushings Companies 2025: Industry Intelligence Report by Spherical Insights (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

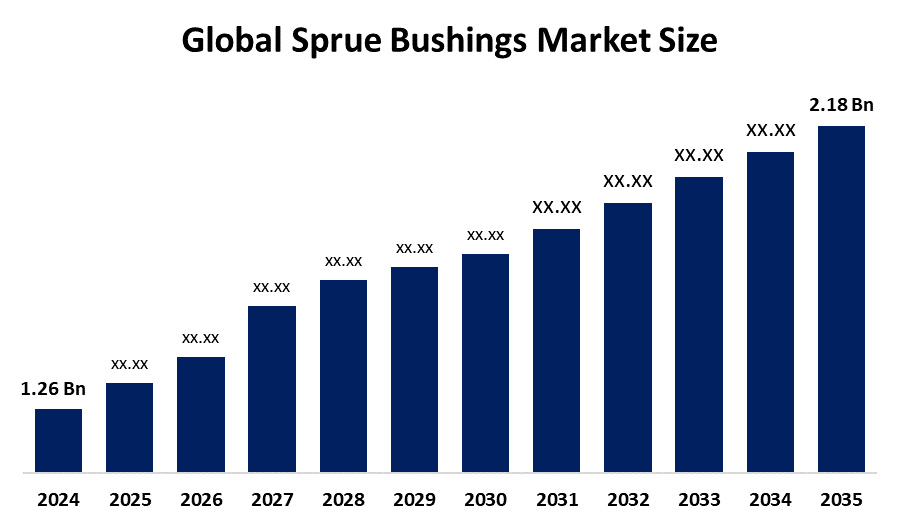

According to a research report published by Spherical Insights & Consulting, The Global Sprue Bushings Market Size is projected to Grow from USD 1.26 Billion in 2024 to USD 2.18 Billion by 2035, at a CAGR of 5.11% during the forecast period 2025–2035. The global Sprue Bushings market is growing because of increased demand from the automotive, electronics, and packaging industries, as well as precision moulding, hot-runner usage, and material developments. Advances in metals and composites improve durability, efficiency, and sustainability, creating major global growth potential.

Introduction

The sprue bushings market is a global industry segment that manufactures, distributes, and uses precision parts used in die casting and injection moulding techniques. Products manufactured from steel, aluminium, and brass are used in major industries like consumer goods, electronics, automotive, and aerospace, which are served by the global sprue bushings market. Its core consists of die casting and injection moulding precision parts that prioritise robustness, automation compatibility, and effective molten material flow. The automotive industry's growing demand for advanced moulding solutions due to lightweight materials and complex geometries is the main driver of market expansion. Demand is further increased by the rise in electric vehicle (EV) production and the growing demand for precise components in the aerospace and electronics industries. Performance gains and longer bushing lifespans are supported by developments in material science, especially the creation of more robust and heat-resistant alloys. The need for dependable, effective bushings is also growing due to automation and the increased use of injection moulding processes. Leading companies like PCS, DME, HASCO, and MISUMI drive the market through constant innovation, while up-and-coming rivals add variety and rivalry. All things considered, segmentation by size, application, and material guarantees customised solutions for a range of sectors.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Sprue Bushings Market.

Sprue Bushings Market Size & Statistics

- The Market Size for Sprue Bushings Was Estimated to be worth USD 1.26 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 5.11% between 2025 and 2035.

- The Global Sprue Bushings Market Size is anticipated to reach USD 2.18 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Sprue Bushings Market

- North America is expected to grow the fastest during the forecast period in the Sprue Bushings Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the sprue bushings market. Another significant market for sprue bushings is North America, which stands out for its highly developed production capabilities and strict quality standards. Major automotive and aerospace manufacturers in the US and Canada are driving the demand for high-performance sprue bushings. The North American market is anticipated to be significantly impacted by the electronics, automotive, and aerospace sectors.

Asia Pacific is expected to generate the highest demand during the forecast period in the sprue bushings market. Its primary drivers are the Asia Pacific's robust manufacturing base and economic growth. The production of consumer goods, electronics, and vehicles in countries like South Korea, Japan, China, and India drives the need for superior sprue bushings. Favourable economic policies and rising industrial investments further reinforce the region's dominant position in terms of global market share and growth potential. Market expansion is supported by the region's investments in industrial automation, skilled labour pool, and favourable economic policies.

Top 10 trends in the Sprue Bushings Market

- Growing automotive demand

- Expansion in electronics & consumer goods

- Adoption of hot runner systems

- Material innovations

- Automation & smart manufacturing

- Customization & precision engineering

- Sustainability focus

- APAC market growth

- Aftermarket & maintenance demand

- Competitive innovation

1. Growing automotive demand

The automotive industry increasingly requires lightweight, complex plastic components for improved performance and fuel efficiency. This demand, coupled with the rise of electric vehicles, drives higher consumption of precision sprue bushings to support advanced injection moulding processes in vehicle manufacturing worldwide.

2. Expansion in electronics & consumer goods

Electronics and consumer products manufacturing rely largely on precision injection molding to produce durable, intricate, and tiny components. The need for sprue bushings, which facilitate effective moulding and guarantee high-quality output in a variety of manufacturing settings, is increased by the growing worldwide consumption of appliances and electronic gadgets.

3. Adoption of hot runner systems

Manufacturers are rapidly shifting from cold runner to hot runner systems due to reduced material waste, shorter cycle times, and enhanced part quality. Sprue bushings designed for hot runners are increasingly in demand, aligning with efficiency, cost reduction, and sustainability goals.

4. Material innovations

Advancements in metallurgy and composites have led to sprue bushings with higher heat resistance, wear durability, and extended operational lifespans. Alloys, stainless steel, and coatings improve molding efficiency, reduce downtime, and allow manufacturers to meet evolving industry demands for reliability and performance.

5. Automation & smart manufacturing

With Industry 4.0 adoption, injection molding is becoming more automated and data-driven. This increases the need for durable sprue bushings capable of withstanding continuous, high-speed production. Smart manufacturing environments prioritize efficiency and minimal downtime, creating opportunities for advanced, precision-engineered bushings.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the sprue bushings market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 14 Companies Leading the Sprue Bushings Market

- FISA Corporation

- YUDO Group

- DME Company

- INCOE Corporation

- Mold-Masters

- PCS Company

- MISUMI Group Inc.

- Thermoplay S.p.A.

- Milacron Holdings Corp.

- Superior Die Set Corporation

- Strack Norma GmbH & Co. KG

- Synventive Molding Solutions

- HASCO Hasenclever GmbH + Co KG

- Mold Hotrunner Solutions Inc. (MHS)

- Others

1. FISA Corporation

Headquarters: Tullahoma, Tennessee

A well-known Japanese maker of precision injection-moulding nozzles has a U.S. marketing, distribution, and service division called FISA Corporation. It was founded in 1996 and specialises in the ground-breaking PLAGATE Hot Runner System, a valve-gated system that eliminates the need for timers, hydraulics, or pneumatics and provides simple installation, a flawless seal, low maintenance, less waste, and quicker cycle times. In 1974, the PLAGATE system was created and recognised for its innovative engineering. FISA provides cutting-edge nozzle technology to businesses in the plastics sector in the United States and selected international markets.

2. YUDO Group

Headquarters: Hwaseong, South Korea

YUDO Group is a leading provider of hot runner systems and auxiliary injection molding solutions, serving industries worldwide. Established in 1980, the company offers mold temperature controllers, PET systems, IML solutions, and robots through subsidiaries like YUDO-STAR and YUDO-SUNS. With over 124 global networks across 40 countries, YUDO supports injection molders in automotive, packaging, electronics, and medical sectors. The company emphasizes smart manufacturing, real-time monitoring, and innovation to deliver high efficiency, precision, and reliability. YUDO is committed to providing advanced, durable, and dependable solutions, helping manufacturers optimize productivity and product quality globally.

3. DME Company

Headquarters: Madison Heights, Michigan, USA

DME Company has been a leader in mold technologies since 1942, offering a comprehensive range of standardized mold components, mold bases, hot runner systems, and controllers. Serving industries such as automotive, medical, and consumer goods, DME provides high-quality, precision-engineered solutions that enhance mold performance and efficiency. Their global presence ensures consistent product quality and reliable service worldwide. DME's commitment to innovation and customer satisfaction makes it a trusted partner for mold makers and manufacturers seeking durable, cost-effective tooling solutions.

4. INCOE Corporation

Headquarters: Auburn Hills, Michigan, USA

INCOE Corporation, founded in 1958, is a pioneer in hot runner systems for injection molding. The company developed the first commercial hot runner nozzle, revolutionizing plastic processing. INCOE offers a wide range of systems, including Direct-Flo™ Gold, Opti-Flo®, and Micro Series, catering to industries such as automotive, medical, and electronics. With manufacturing facilities in North America, Europe, Asia, and South America, INCOE supports customers globally through a network of technical representatives in over 45 countries. The company is committed to providing high-performance, reliable solutions that enhance productivity and sustainability in injection molding operations.

5. Mold-Masters

Headquarters: Georgetown, Ontario, Canada

Mold-Masters is a global leader in hot runner systems and auxiliary injection molding solutions, founded in 1963 by Jobst and Waltraud Gellert. The company designs, manufactures, and services highly engineered plastic processing equipment, including hot runners, temperature controllers, and co-injection systems. Mold-Masters serves industries such as automotive, medical, and consumer goods, providing innovative technologies that optimize production, enhance molded part quality, and reduce costs. With a global presence and a commitment to sustainability and performance, Mold-Masters continues to deliver superior solutions to customers worldwide.

Are you ready to discover more about the Sprue Bushings market?

The report provides an in-depth analysis of the leading companies operating in the global sprue bushings market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes

Company Profiles

- FISA Corporation

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- YUDO Group

- DME Company

- INCOE Corporation

- Mold-Masters

- PCS Company

- MISUMI Group Inc.

- Thermoplay S.p.A.

- Milacron Holdings Corp.

- Superior Die Set Corporation

- Strack Norma GmbH & Co. KG

- Synventive Molding Solutions

- HASCO Hasenclever GmbH + Co KG

- Mold Hotrunner Solutions Inc. (MHS)

- Others

Conclusion

The global market for sprue bushings is expected to increase steadily because to new material developments, growing applications in the consumer goods, electronics, and automotive industries, and technological improvements. Injection moulding operations are made more precise, dependable, and efficient by improved designs and long-lasting materials. Demand is fuelled by expansion in the automotive, electronics, and industrial manufacturing sectors, while customisation choices and automation integration enhance operational flexibility. Despite obstacles like high production costs and competitive pressures, sprue bushings are positioned as crucial parts of contemporary precision moulding and manufacturing operations across the globe due to continuous research and development, quality enhancements, and smart international expansion.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?