World’s Top 50 Companies in Metal Fabrication Equipment Market in 2025 Watchlist: Statistical Report (2024 2035)

RELEASE DATE: Aug 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

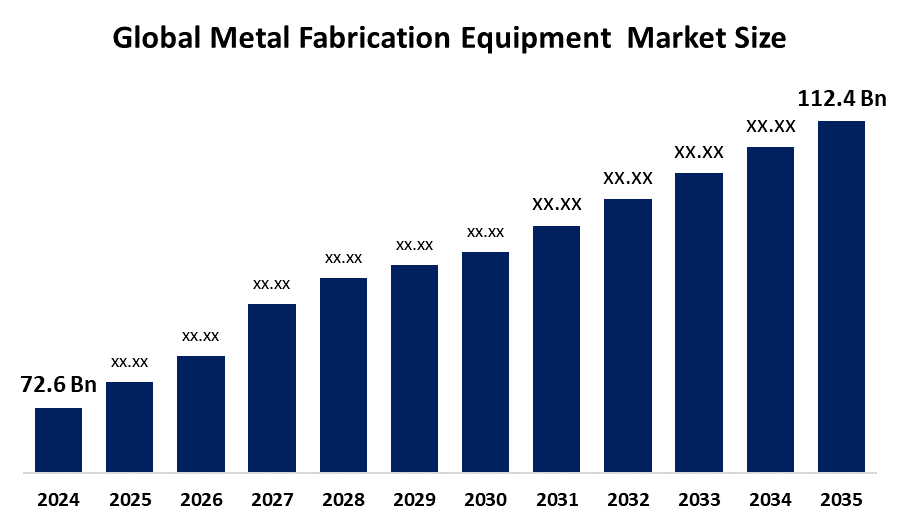

According to a research report published by Spherical Insights & Consulting, The Global Metal Fabrication Equipment Market Size is projected to grow from USD 72.6 Billion in 2024 to USD 112.4 Billion by 2035, at a CAGR of 4.05% during the forecast period 2025–2035. Increasing demand for machining and metal processing in developing countries is expected to drive the market. The Asia Pacific is expected to lead the market over the forecast period.

Introduction

The metal fabrication equipment market involves machinery used to cut, shape, and assemble metal components for various industries like automotive, construction, and aerospace. The increased production efficiency, precision, and reduced labor costs. Growing industrialization and demand for customized metal products create significant opportunities. Governments worldwide support this market through initiatives promoting manufacturing modernization, automation, and Make in campaigns to boost domestic production. Investments in advanced technologies like CNC machines and robotics further drive market growth and innovation.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Metal Fabrication Equipment Market.

- Metal Fabrication Equipment Market Size & Statistics

- The Market Size for Metal Fabrication Equipment Was Estimated to be worth USD 72.6 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 4.05% between 2025 and 2035.

- The Global Metal Fabrication Equipment Market Size is anticipated to reach USD 112.4 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Metal Fabrication Equipment Market

- Europe is expected to grow the fastest during the forecast period in the Metal Fabrication Equipment Market.

Regional growth and demand

Europe is expected to grow the fastest during the forecast period in the metal fabrication equipment market. The focus on Industry 4.0 projects and sophisticated manufacturing technology. In metal fabrication, nations like France, Italy, and Germany are leading the way in implementing automation, robotics, and the Internet of Things, which results in increased productivity and efficiency. Additionally, investments in cutting-edge, energy-efficient metal fabrication equipment are derived by the region's strong emphasis on sustainable practices and the shift to green manufacturing.

Asia Pacific is expected to generate the highest demand during the forecast period in the metal fabrication equipment market. The worldwide market for metal manufacturing equipment for the anticipated period. The fast growth of industrial sectors in nations like China, India, Japan, and South Korea is driving the North American market. The demand for metal fabrication equipment is fueled by these countries' thriving manufacturing sectors and expenditures in infrastructure development.

Top 10 trends in the Metal Fabrication Equipment Market

- Automation & Robotics

- CNC Technology Advancements

- Integration of IoT and Industry 4.0

- Additive Manufacturing (3D Printing)

- Lightweight and High-Strength Materials

- Energy-Efficient Equipment

- Customization and Flexibility

- Improved Safety Features

- Remote Monitoring and Maintenance

- Rising Demand from Emerging Markets

1. Automation & Robotics

Automation and robotics are transforming the metal fabrication equipment market by enhancing precision, productivity, and safety. Automated systems reduce manual labor, minimize errors, and enable 24/7 operation, leading to higher efficiency and lower production costs. Robotics is increasingly used for tasks like welding, cutting, and material handling. This trend is driven by labor shortages, rising demand for customized products, and the push for smart manufacturing. As a result, automation is becoming essential for competitiveness and scalability in the metal fabrication industry.

2. CNC Technology Advancements

Advancements in CNC (Computer Numerical Control) technology are significantly impacting the metal fabrication equipment market by enabling greater precision, speed, and automation. Modern CNC machines offer enhanced software integration, multi-axis capabilities, and real-time monitoring, which streamline complex metalworking tasks such as cutting, drilling, and milling. These innovations reduce waste, lower operational costs, and improve product consistency. As industries demand higher efficiency and customization, CNC advancements are becoming essential, driving adoption across sectors like aerospace, automotive, and heavy machinery manufacturing.

3. Integration of IoT & Industry 4.0

The integration of IoT and Industry 4.0 is revolutionizing the metal fabrication equipment market by enabling smart, connected manufacturing. IoT-enabled machines collect real-time data for monitoring performance, predicting maintenance needs, and improving operational efficiency. Industry 4.0 technologies support automation, digital twins, and remote diagnostics, enhancing productivity and reducing downtime. This digital transformation allows manufacturers to optimize resource use, ensure quality control, and respond quickly to changing demands. As a result, smart fabrication systems are becoming essential in modern industrial operations.

4. Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is reshaping the metal fabrication equipment market by enabling the creation of complex, lightweight metal parts with high precision and minimal material waste. Unlike traditional subtractive methods, it builds components layer by layer, reducing production time and cost. This technology is increasingly used in aerospace, automotive, and medical industries for prototyping and custom manufacturing. As demand for innovation and flexibility grows, 3D printing is becoming a key complement to conventional metal fabrication processes, driving market evolution.

5. Lightweight & High-Strength Materials

The growing use of lightweight and high-strength materials like advanced alloys and composites is influencing the metal fabrication equipment market to adapt and innovate. Fabrication machinery is being enhanced to handle these tougher, more specialized materials with precision and efficiency. This trend is driven by industries such as automotive and aerospace seeking fuel efficiency and durability. Equipment capable of processing these materials supports manufacturers in meeting performance and sustainability goals, thus expanding opportunities and driving advancements in metal fabrication technology.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the metal fabrication equipment market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 12 Companies Leading the Metal Fabrication Equipment Market

- Trumpf Group

- Amada Co., Ltd.

- Mitsubishi Electric Corporation

- Bystronic AG

- Mazak Corporation

- Haco Group

- Komatsu Ltd.

- Lincoln Electric Holdings, Inc.

- LVD Group

- Prima Industrie S.p.A.

- 1Haco, Inc.

- FANUC Corporation

- Others

1. Trumpf Group

Headquarters: Ditzingen, Germany

Trumpf Group, a prominent German industrial leader, specializes in advanced metal fabrication solutions, including laser cutting, punching, bending, and robotic welding technologies used across multiple sectors. With an estimated 25% market share and annual revenues of approximately USD 4 billion, the company is recognized for its energy-efficient, AI-driven innovations. Strategic initiatives such as intelligent software development, smart factory collaborations, and sustainable cooling systems enhance precision, automation, and productivity in global sheet-metal manufacturing.

2. Amada Co., Ltd.

Headquarters: Isehara, Kanagawa, Japan

Amada Co., Ltd. is a global frontrunner in metalworking machinery, delivering comprehensive sheet metal fabrication, micro-welding, cutting, grinding, stamping presses, and press automation solutions. Its integrated offerings encompass machinery, software, tooling, and maintenance services, catering to industries such as automotive, medical devices, electronics, and home appliances.

3. Mitsubishi Electric Corporation

Headquarters: Tokyo, Japan

Mitsubishi Electric provides end-to-end metal fabrication capabilities through its extensive factory automation portfolio, including high-precision laser processing machines, EDMs (electrical discharge machines), electron beam machines, and CNC controllers. The company’s integration with smart manufacturing ecosystems like e-Factory and developments such as LASORTING—a fully automated laser cutting, sorting, and storage system—improve operational flexibility, efficiency, and automation across industries including automotive, aerospace, and electronics.

4. Bystronic AG

Headquarters: Niederönz, Canton of Bern, Switzerland

Bystronic AG is a leading innovator in sheet metal processing, offering premium laser cutting systems, tube lasers, press brakes, automation solutions, software, and support services. With a focus on complete production chain automation, digital integration through the BySoft Suite, and intelligent manufacturing solutions, Bystronic helps industries achieve high precision, operational efficiency, and sustainable production.

5. Mazak Corporation (Yamazaki Mazak Corporation)

Headquarters: Tokyo, Japan

Yamazaki Mazak Corporation is a major Japanese manufacturer of advanced machinery, providing multi-tasking and 5-axis machining centers, CNC turning centers, laser processing machines, additive manufacturing (AM) systems, and friction stir welding (FSW) solutions. Serving sectors such as automotive, aerospace, semiconductors, construction, and agriculture, Mazak integrates automation, high-precision engineering, and process optimization to maintain a competitive position in the global metal fabrication equipment market.

Are you ready to discover more about the Metal Fabrication Equipment market?

The report provides an in-depth analysis of the leading companies operating in the global metal fabrication equipment market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Trumpf Group

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Amada Co., Ltd.

- Mitsubishi Electric Corporation

- Bystronic AG

- Mazak Corporation

- Haco Group

- Komatsu Ltd.

- Lincoln Electric Holdings, Inc.

- LVD Group

- Prima Industrie S.p.A.

- Haco, Inc.

- FANUC Corporation

- Others

Conclusion

The metal fabrication equipment market is poised for robust growth, driven by rising industrialization, demand for customized products, and government initiatives promoting automation and modernization. Europe leads in adopting Industry 4.0 technologies, emphasizing sustainable and energy-efficient manufacturing. Meanwhile, the Asia Pacific region dominates demand due to rapid industrial expansion and infrastructure investments in countries like China, India, and Japan. Advancements in CNC machines, robotics, and smart technologies are key drivers, ensuring enhanced productivity, precision, and sustainable growth worldwide.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Follow Us: LinkedIn | Facebook | Twitter

Need help to buy this report?