World’s Top 50 Companies in Direct to Film Printing 2025 Watchlist: Statistical Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

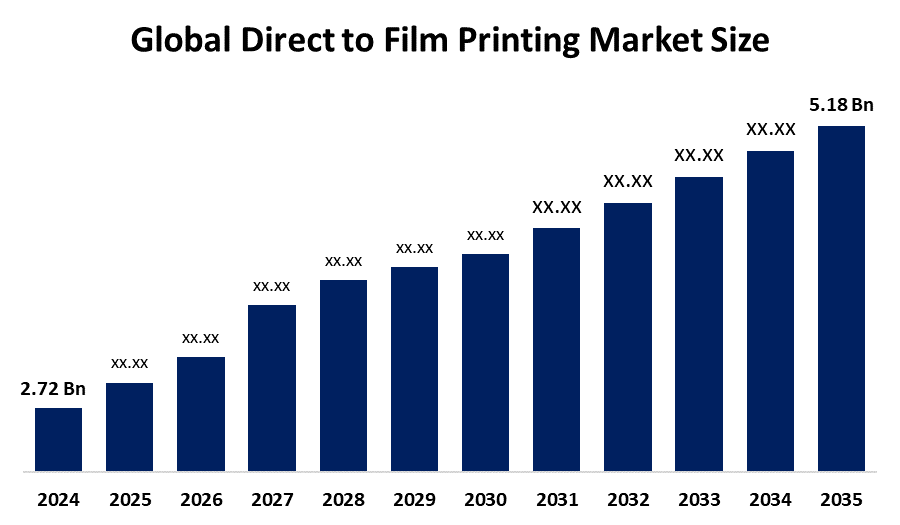

According to a research report published by Spherical Insights & Consulting, The Global Direct to Film Printing Market Size is projected to Grow from USD 2.72 Billion in 2024 to USD 5.18 Billion by 2035, at a CAGR of 6.03% during the forecast period 2025–2035. The market for direct-to-film printing is in greater demand because of the growing need for personalised, on-demand clothing, which is difficult for standard printing techniques to effectively meet. DTF promotes efficiency and versatility by enabling vivid, high-quality transfers on a variety of materials with less setup time. The growth of small-batch textile production, rapid fashion, and e-commerce adds momentum.

Introduction

A Direct-to-Film (DTF) printing is a heat-transfer technique that starts with CMYK and white inks printing a design onto a specific PET film. Using specialised printers, films, and heat-press equipment, the DTF printing business uses a film-based heat-transfer method to transfer high-resolution images onto a variety of textile substrates, including T-shirts, hoodies, sportswear, and accessories. The proliferation of e-commerce and changing fashion trends has led to a surge in demand for personalised and on-demand clothing, which is one of the main growth factors. Especially for customised goods, the technique is quite alluring due to its affordability, fabric adaptability, and capacity to produce vivid images in tiny quantities. Hybrid printing equipment that combines DTF and DTG capabilities has democratised the market and given firms flexibility and increased production efficiency. Sustainability is becoming more popular with customisation. In order to reduce their environmental impact and adhere to stricter rules, manufacturers are switching to recyclable materials, biodegradable films, and water-based inks. In the future, industrial operations will be more intelligent, quicker, and adaptable thanks to automation, AI integration, and modular equipment designs. In the meantime, the sector is becoming more and more regarded for facilitating micro-fulfillment, cutting waste through small-batch manufacturing, and providing quick turnaround that satisfies customer demands for customisation.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Direct to Film Printing Market.

Direct to Film Printing Market Size & Statistics

- The Market Size for Direct to Film Printing Was Estimated to be worth USD 2.72 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 6.03% between 2025 and 2035.

- The Global Direct to Film Printing Market Size is anticipated to reach USD 5.18 Billion by 2035.

- Europe is expected to generate the highest demand during the forecast period in the Direct to Film Printing Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Direct to Film Printing Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the direct-to-film printing market. The market for direct-to-film printings is now growing in the Asia Pacific due to the rising consumer demand for personalised and on-demand garments, and the quick uptake of cutting-edge DTF technology is the main cause of this increase. China is driving regional growth due to advancements in DTF solutions and a rise in the apparel industry.

Europe is expected to generate the highest demand during the forecast period in the direct-to-film printing market. The direct-to-film printing market with the quickest rate of growth throughout the study period is anticipated to be in Europe, driven by the expanding use of digital textile printing solutions, the adoption of sustainable printing techniques, and the rising desire for customised, on-demand clothing. With the help of its thriving textile industry, environmentally acceptable printing technology, and growing demand for short-run custom clothing printing, Germany has become a major regional player.

Top 10 trends in the Direct to Film Printing Market

- Eco-Friendly Ink Innovations

- Automation & AI Integration

- Faster Print Speeds

- Advanced Software and RIP Systems

- Expanded Industry Applications

- Versatile Film Innovations

- Hybrid & UV DTF Technologies

- E-Commerce Integration

- Focus on Sustainability

- Global Market Expansion

1. Eco-Friendly Ink Innovations

Direct-to-film printing is being revolutionised by eco-friendly ink breakthroughs, which offer sustainable substitutes that lessen their negative effects on the environment without sacrificing print quality. Water-based inks that are non-toxic and biodegradable are replacing conventional solvent-based inks that release volatile organic compounds. These inks provide outstanding adherence and vivid colours on a variety of cloth types. Concerns around plastic waste have also been addressed by developments that have produced recyclable and biodegradable transfer films. These films assist a circular economy and lessen landfill accumulation because they can be recycled or decompose organically. Additionally, DTF printing procedures use less energy and leave fewer carbon imprints due to energy-efficient printing equipment like LED curing technologies.

2. Automation & AI Integration

Automation and artificial intelligence are transforming businesses through increased scalability, precision, and efficiency. AI-driven automation optimises workflows and lowers operating costs by allowing systems to complete complicated tasks with little assistance from humans. Artificial intelligence algorithms are used in manufacturing to evaluate real-time data and forecast maintenance requirements, reducing downtime and increasing equipment longevity. Chatbots driven by AI in customer service offer prompt responses, enhancing user satisfaction and experience. Additionally, through the analysis of customer behaviour and preferences, AI integration makes personalised marketing techniques possible. The combination of automation and AI is anticipated to spur innovation and competitiveness in a number of industries as companies continue to implement AI technologies.

3. Faster Print Speeds

The Direct-to-film printing trend of quicker print speeds is revolutionising the textile and customisation sectors by facilitating high-volume production with shorter turnaround times. With the help of sophisticated printhead technologies, including intelligent print path algorithms and multi-carriage systems, modern DTF printers can produce custom transfers quickly. These developments make it easier to manage big orders, including ones with distinctive designs, effectively without sacrificing print quality. Further streamlining the printing process, reducing manual intervention, and increasing overall productivity is achieved by integrating automated features like automatic media loading and unloading. This increase in printing speed helps companies fulfil deadlines and react quickly to market needs, securing DTF printing's place as the go-to technique for on-demand clothing embellishment.

4. Advanced Software and RIP Systems

Direct-to-film printing is greatly improved by Advanced Raster Image Processor software, which ensures high-quality outputs and streamlines procedures. With capabilities like layout nesting, automated task queuing, and a smooth interface with prepress and postpress components, modern RIP solutions drastically cut down on setup time and user involvement. Additionally, they offer tools for colour calibration and precise white ink management, guaranteeing perfect colour reproduction on a variety of substrates. Furthermore, certain RIP software allows for proactive management of print jobs and equipment by providing real-time monitoring and maintenance notifications. These developments facilitate scalability in high-volume manufacturing settings in addition to increasing operational efficiency. DTF printers can provide reliable, colourful prints while maximising resource use and saving waste by implementing cutting-edge RIP software.

5. Expanded Industry Applications

Direct-to-film printing has quickly broadened its use beyond conventional textiles, allowing for customisation in a number of sectors. This adaptability enables companies to provide customised goods made from metals, glass, wood, and ceramics. For example, it is now possible to create promotional goods, signage, and personalised mugs with vivid colours and sophisticated designs. Opportunities for distinctive product offers are created by the technology's versatility, which extends to uneven surfaces like shoes and home décor pieces like pillows and curtains. DTF printing is also used in industrial industries to mark and label durable goods, improving compliance and branding. Because of its many uses, DTF printing is a useful tool for companies looking to expand their product lines and satisfy the rising demand for customised goods.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the direct-to-film printing market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 15 Companies Leading the Direct to Film Printing Market

- Axiom America, LLC

- ColDesi, Inc.

- KORNIT DIGITAL LTD

- Adelco Screen Process Ltd.

- Seiko Epson Corporation

- Roland DG Corporation

- Ricoh Company, Ltd.

- MIMAKI ENGINEERING CO., LTD.

- Aeoon Technologies GmbH

- Brother International Corporation

- Xerox Corporation

- Lexmark International

- Hexis S.A.

- Muller Martini

- SUN Innovations

- Others

1. Axiom America, LLC

Headquarters: Colorado and Irwindale, California

Axiom America, LLC is a well-known textile decorating technology company with headquarters in the United States. They specialise in Direct-to-Film printing solutions. With its main office located in High Point, North Carolina, the corporation also has regional offices and shipping hubs in Irwindale, California, and Colorado Springs, Missouri. Among the many goods and services that Axiom America provides are DTF printers, heat presses, laser cutting machines, sublimation equipment, and embroidery machines. To meet the needs of bespoke garment businesses, their Arcus DTF printers are made to produce high-quality prints on a variety of materials and substrates. In the highly competitive textile decoration sector, the company is renowned for its dedication to client satisfaction by offering customised solutions and knowledgeable technical assistance.

2. ColDesi, Inc.

Headquarters: Tampa, Florida

A corporation established in the United States, ColDesi, Inc., specialises in supplies and equipment for the custom products sector. ColDesi, which has its headquarters in Tampa, Florida, provides a wide range of solutions, such as rhinestone systems, embroidery machines, UV printers, heat presses, direct-to-film, and direct-to-garment printers. The company is dedicated to offering companies in the customisation industry top-notch goods and services. ColDesi's products are made to satisfy the various demands of sign makers, promotional product designers, and custom clothing decorators, allowing them to create customised goods quickly and effectively. ColDesi remains a valued partner for companies looking for dependable and cutting-edge customisation solutions because of its emphasis on innovation and customer satisfaction.

3. KORNIT DIGITAL LTD

Headquarters: Rosh HaAyin, Israel

Direct-to-garment and direct-to-fabric technologies are the areas of expertise for Kornit Digital Ltd., a global leader in environmentally friendly digital textile printing solutions. In addition to its modern ink manufacturing facilities in Kiryat Gat, Israel, the company has its headquarters in Rosh HaAyin, Israel. Kornit provides a wide range of products under the Kornit name, such as textile dryers, ink consumables, and digital printing equipment. Items including bags, beachwear, jeans, dresses, fabrics, furnishings, jackets, leggings, pants, pillows, suits, t-shirts, and tops all use its solutions. By enabling sustainable, on-demand production, the company's cutting-edge technologies seek to transform the textile sector. Offering state-of-the-art solutions that meet the changing demands of the fashion and textile industries, Kornit Digital services clients globally.

4. Adelco Screen Process Ltd.

Headquarters: Shanghai, China

The UK-based company Adelco Screen Process Ltd. specialises in screen printing and drying solutions for the apparel sector. The company has its headquarters in Bordon, Hampshire, and runs a cutting-edge production plant close to Shanghai, China. Adelco provides a wide range of equipment, such as Direct-to-Film printers, Oval Automatic Screen Printing Presses, and Jet Air Conveyor Drying Systems. Their goods are made to satisfy the requirements of large-scale textile printing, offering dependable and effective solutions for companies that produce personalised clothing. With more than 40 years of expertise, Adelco has built a solid international reputation and serves clients on six continents. The business has established itself as a reliable partner in the clothing printing sector thanks to its dedication to quality and innovation.

5. Seiko Epson Corporation

Headquarters: Nagano Prefecture, Japan

The headquarters of the international electronics corporation Seiko Epson Corporation, usually referred to as Epson, is located in Suwa, Nagano Prefecture, Japan. Epson is well known for its advancements in precision technology, printing, and imaging. Inkjet printers, 3LCD projectors, industrial robots, smart glasses, watches, and semiconductors are among its product offerings. With operations in more than 90 countries and regions, the firm is a worldwide player. The goal of Epson's energy-efficient, high-precision, and compact technologies is to benefit society. In order to balance its operations with nature and lessen its influence on the environment, the corporation places a strong emphasis on environmental sustainability. Epson is a leader in the electronics sector due to its dedication to sustainability and innovation. The organisation keeps creating and delivering goods that satisfy the changing demands of businesses and customers around the globe.

Are you ready to discover more about the direct to film printing market?

The report provides an in-depth analysis of the leading companies operating in the global direct to film printing market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Axiom America, LLC

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- ColDesi, Inc.

- KORNIT DIGITAL LTD

- Adelco Screen Process Ltd.

- Seiko Epson Corporation

- Roland DG Corporation

- Ricoh Company, Ltd.

- IBM

- MIMAKI ENGINEERING CO., LTD.

- Others

Conclusion

The direct to film printing market is accelerating due to the growing demand for customised and on-demand clothing, the uptake of cutting-edge printing technologies, and growing corporate awareness of DTF printing's affordability and versatility over conventional techniques are all contributing factors to the direct-to-film printing market's notable expansion. Market growth is further accelerated by the growth of e-commerce and the fashion sector. The need for DTF printing has been greatly boosted by government backing for growing textile production as well as rising private sector investments to keep up with changing fashion trends. The bespoke apparel industry's growing small businesses and entrepreneurial spirit are also important drivers of market expansion.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?