World's Top 40 Companies in Molybdenum Sheets in 2025 Watch List: Statistics Report (2024–2035).

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

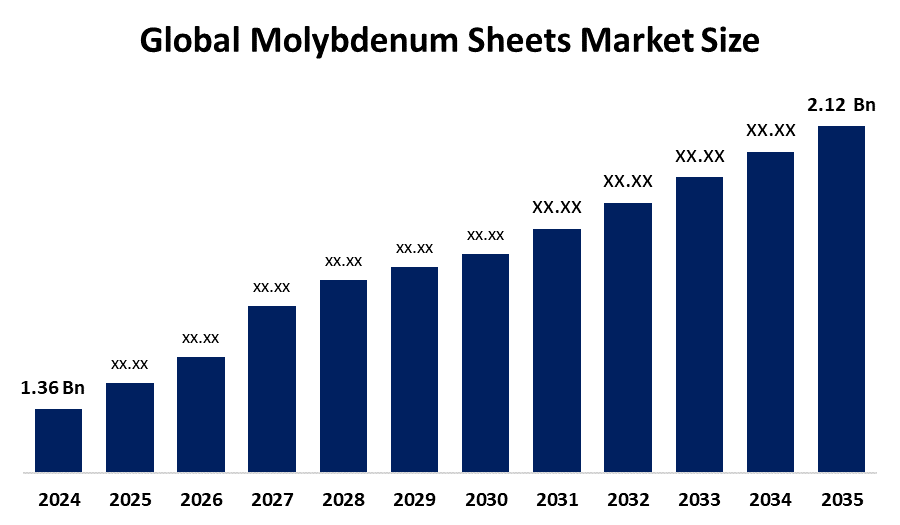

According to a research report published by Spherical Insights & Consulting, The Global Molybdenum Sheets Market Size is projected Grow from USD 1.36 Billion in 2024 to USD 2.12 Billion by 2035, at a CAGR of 4.12 % during the forecast period 2025–2035. The Molybdenum Sheets market offers future opportunities through rising demand in aerospace, electronics, and energy sectors, driven by high-temperature resistance, conductivity, and renewable energy applications, alongside advancements in manufacturing and material innovations.

Introduction

The Molybdenum Sheets Market Size is gaining momentum due to the metal’s unique properties such as high melting point, excellent thermal and electrical conductivity, and superior corrosion resistance. Widely used in aerospace, electronics, energy, and industrial applications, molybdenum sheets are vital for producing furnace components, semiconductors, and defense equipment. The market is driven by growing demand for high-performance materials in emerging technologies and renewable energy projects. Increasing investments in aerospace and electronics manufacturing, particularly in Asia-Pacific and North America, further boost growth. Additionally, advancements in processing techniques and sustainable mining practices are expected to create new opportunities during the forecast period.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Molybdenum Sheets market.

Molybdenum Sheets Market Size & Statistics

- The Market Size for Molybdenum Sheets Was Estimated to be Worth USD 1.36 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 4.12 % Between 2025 and 2035.

- The Global Molybdenum Sheets Market Size is Anticipated to Reach USD 2.12 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Molybdenum Sheets market.

- North America is expected to grow the fastest during the forecast period in the Molybdenum Sheets market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the Molybdenum Sheets market. Asia Pacific leads demand due to rapid industrialization, expanding electronics and aerospace sectors, growing solar and energy applications, and strong government support for advanced materials, driving high consumption of molybdenum sheets in manufacturing and high-temperature applications.

North America is expected to generate the highest demand during the forecast period in the Molybdenum Sheets market. North America’s rapid growth is driven by advanced aerospace, defense, and electronics industries, strong R&D investments, adoption of high-performance materials, and technological innovations requiring molybdenum sheets for high-temperature, corrosion-resistant, and energy-efficient applications.

Top 5 Trends in Molybdenum Sheets Market

1. Growing Demand in Aerospace and Defense:

Molybdenum sheets are increasingly used in aerospace and defense due to their high melting point, strength, and corrosion resistance. Applications include aircraft engine components, missile parts, and thermal shielding. Rising air travel, defense modernization programs, and space exploration initiatives in North America, Europe, and Asia-Pacific are driving adoption. The material’s ability to withstand extreme temperatures and mechanical stress ensures durability and reliability in critical components. Continuous R&D in lightweight, high-performance alloys further supports market expansion. Aerospace and defense sectors are projected to remain primary demand drivers.

2. Expansion in Electronics and Semiconductor Applications:

The electronics and semiconductor industry is a major growth area for molybdenum sheets. These sheets are used in thin-film transistors, solar panels, LED substrates, and semiconductor components due to excellent thermal and electrical conductivity. The increasing miniaturization of devices, rising demand for efficient photovoltaics, and expansion of high-performance computing and 5G infrastructure contribute to higher consumption. Molybdenum’s stability under high-temperature processing conditions and compatibility with advanced manufacturing processes make it essential. With the global electronics market growing steadily, this trend offers significant long-term opportunities for molybdenum sheet suppliers and manufacturers.

3. Adoption in Energy and Power Generation:

Molybdenum sheets are widely utilized in power generation, including nuclear reactors, solar thermal systems, and high-efficiency boilers. Their high-temperature stability, corrosion resistance, and thermal conductivity make them ideal for energy applications. The push for renewable energy, including concentrated solar power, and modernization of conventional power plants, drives demand. Government incentives for clean energy projects and the development of energy-efficient technologies further boost usage. Additionally, energy sector regulations emphasizing safety and durability increase reliance on high-performance materials. Molybdenum sheets are increasingly critical in both conventional and renewable energy applications, making this sector a consistent growth driver.

4. Technological Advancements in Manufacturing Processes:

Advancements in rolling, forging, and coating technologies are enhancing molybdenum sheet performance, enabling precise thickness, uniformity, and surface finish. Innovations in powder metallurgy and sintering techniques allow production of custom alloys for specialized applications. Additive manufacturing integration is creating opportunities for complex component designs. These technological improvements reduce material wastage, improve strength-to-weight ratios, and enhance thermal stability. Manufacturers are increasingly adopting automated and AI-driven production systems for consistent quality and cost efficiency. Technological progress also opens new end-use sectors, including advanced electronics, aerospace, and medical devices, boosting the overall market growth and competitiveness of molybdenum sheets.

5. Rising Focus on Sustainability and Recycling:

Sustainability trends are influencing molybdenum sheet production, with emphasis on recycling scrap, reducing energy consumption, and minimizing environmental impact. Manufacturers are adopting cleaner smelting processes, waste recovery techniques, and renewable energy in production. Recycling molybdenum from industrial scrap reduces raw material dependency and lowers carbon footprint. Increasing global regulations and corporate ESG commitments further push for eco-friendly manufacturing. The combination of environmental compliance and cost-efficiency makes recycled and sustainably produced molybdenum sheets attractive for end-users in aerospace, electronics, and energy sectors. This trend promotes long-term growth while aligning with global sustainability initiatives.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Molybdenum Sheets market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 13 Companies Leading the Molybdenum Sheets Market

- Plansee Group

- H.C. Starck Solutions

- MolyWorks Materials Corporation

- Global Tungsten & Powders

- China Molybdenum Co., Ltd.

- Luoyang Rare Metal Research Material Co., Ltd.

- Midwest Tungsten Service

- Ed Fagan Inc.

- ALB Materials Inc.

- Stanford Advanced Materials

- Zhuzhou Jiabang Refractory Metal Co., Ltd.

- American Elements

- Other

1. Plansee Group

Headquarters: Reutte, Austria

Plansee Group is a global leader in refractory metals, including molybdenum, tungsten, and tantalum products. The company specializes in high-performance sheets, powders, and components used in aerospace, electronics, energy, and medical industries. Known for precision manufacturing and material expertise, Plansee delivers solutions for extreme-temperature and high-stress applications. Strong R&D capabilities allow it to innovate advanced alloys and coatings. The company emphasizes sustainability, quality control, and global customer support. With production facilities and distribution networks worldwide, Plansee continues to expand its presence, providing high-purity molybdenum sheets for industrial, technological, and research applications.

2. H.C. Starck Solutions

Headquarters: Goslar, Germany

H.C. Starck Solutions is a leading provider of refractory metals, including molybdenum, tungsten, and niobium products. The company offers sheets, foils, powders, and components tailored for aerospace, electronics, lighting, and industrial applications. Known for material purity and precision, H.C. Starck focuses on high-performance solutions capable of withstanding extreme temperatures and corrosive environments. Its extensive R&D efforts ensure innovation in alloys, coatings, and customized material solutions. With global production and service networks, H.C. Starck supports customers across multiple industries, emphasizing reliability, sustainability, and technical expertise. Its molybdenum sheets are widely used in energy, defense, and semiconductor applications.

3. MolyWorks Materials Corporation

Headquarters: Bozeman, Montana, USA

MolyWorks Materials Corporation specializes in the manufacture and supply of high-purity molybdenum products, including sheets, plates, and foils. Serving aerospace, defense, electronics, and industrial markets, the company focuses on delivering materials with exceptional thermal and mechanical performance. MolyWorks emphasizes advanced manufacturing techniques and stringent quality control to meet demanding specifications for extreme environments. Its solutions support research, precision engineering, and high-temperature applications. With a customer-centric approach, MolyWorks collaborates closely with clients to develop tailored solutions. The company’s molybdenum sheets are highly valued for durability, conductivity, and resistance to corrosion, making it a trusted supplier in global high-tech industries.

4. Global Tungsten & Powders

Headquarters: Towanda, Pennsylvania, USA

Global Tungsten & Powders (GTP) is a leading manufacturer of refractory metals and alloys, providing high-purity molybdenum sheets, tungsten powders, and components for aerospace, electronics, defense, and energy sectors. The company emphasizes material performance, innovation, and precision engineering for extreme-temperature and high-stress applications. GTP invests heavily in R&D, developing custom alloys and advanced processing techniques to meet specialized customer requirements. Its products are widely used in thermal management, lighting, semiconductor, and industrial applications. With a global customer base and production facilities, GTP focuses on sustainability, quality assurance, and technical support, maintaining a strong position in the refractory metals market.

5. China Molybdenum Co., Ltd.

Headquarters: Luoyang, China

China Molybdenum Co., Ltd. is a leading mining and materials company specializing in molybdenum, tungsten, copper, and cobalt production. The company produces high-purity molybdenum sheets, powders, and alloys for industrial, energy, and technological applications. With significant vertical integration, it manages mining, processing, and global distribution. China Molybdenum invests in R&D and advanced manufacturing technologies to enhance material quality, durability, and performance. Its molybdenum sheets are used in aerospace, electronics, and energy industries, supporting high-temperature and high-stress applications. Focused on sustainability, safety, and innovation, the company is a key global player in refractory metal supply and advanced material solutions.

Are you ready to discover more about the Molybdenum Sheets market?

The report provides an in-depth analysis of the leading companies operating in the global Molybdenum Sheets market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Plansee Group.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- H.C. Starck Solutions

- MolyWorks Materials Corporation

- Global Tungsten & Powders

- China Molybdenum Co., Ltd.

- Luoyang Rare Metal Research Material Co., Ltd.

- Midwest Tungsten Service

- Ed Fagan Inc.

- ALB Materials Inc.

- Stanford Advanced Materials

Conclusion

The Molybdenum Sheets market is poised for steady growth, driven by expanding applications in aerospace, defense, electronics, energy, and industrial sectors. Rising demand for high-performance, corrosion-resistant, and thermally stable materials underscores the strategic importance of molybdenum sheets. Technological advancements in manufacturing, including precision rolling, additive manufacturing, and coating innovations, are enhancing product quality and enabling new applications. Sustainability initiatives, recycling, and eco-friendly production practices are increasingly shaping the market landscape. Companies focusing on R&D, global expansion, and customized solutions are well-positioned to capitalize on opportunities, while regional growth in Asia-Pacific and North America continues to drive market momentum and competitiveness.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?