World's Top 40 Companies in Injectors for Diffusion Lpcvd Market in 2025 Watch List: Statistics Report (2024–2035).

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

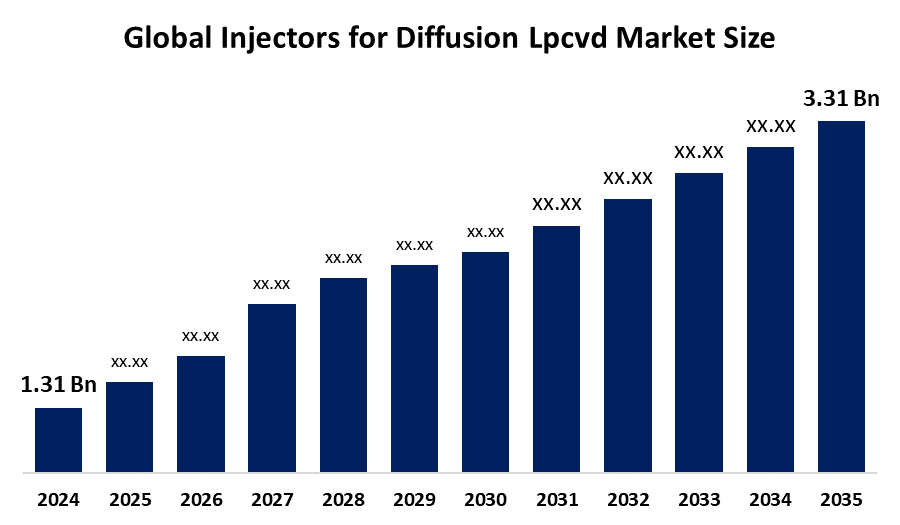

According to a research report published by Spherical Insights & Consulting, The Global Injectors for Diffusion Lpcvd Market Size is projected To Grow from USD 1.31 Billion in 2024 to USD 3.31 Billion by 2035, at a CAGR of 8.79 % during the forecast period 2025–2035. The Injectors for Diffusion LPCVD market offers growth opportunities driven by increasing semiconductor fabrication, demand for uniform thin films, advanced microelectronics, MEMS devices, and rising adoption of energy-efficient, high-precision deposition technologies.

Introduction

The Injectors for Diffusion LPCVD (Low-Pressure Chemical Vapor Deposition) Market Size is witnessing rapid growth due to increasing demand for high-performance semiconductor devices and advanced microelectronics. LPCVD injectors play a critical role in ensuring uniform gas flow, precise deposition, and high-quality thin films on wafers, which are essential for ICs, MEMS, and photovoltaic applications. As semiconductor manufacturers focus on miniaturization, energy efficiency, and superior device performance, the adoption of advanced LPCVD injector systems is rising. Technological advancements, process optimization, and growing investments in semiconductor fabrication facilities worldwide are further driving the market, positioning it for sustained expansion.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Injectors for Diffusion Lpcvd market.

Injectors for Diffusion Lpcvd Market Size & Statistics

- The Market for Injectors for Diffusion Lpcvd Was Estimated to be Worth USD 1.31 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 8.79 % Between 2025 and 2035.

- The Global Injectors for Diffusion Lpcvd Market Size is Anticipated to Reach USD 3.31 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Injectors for Diffusion Lpcvd Market.

- North America is expected to grow the fastest during the forecast period in the Injectors for Diffusion Lpcvd Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Injectors for Diffusion Lpcvd market. This growth is driven by advanced semiconductor manufacturing, strong R&D infrastructure, and early adoption of cutting-edge LPCVD technologies. The presence of leading semiconductor companies, increased investment in chip fabrication, and rising demand for high-performance electronics, including memory devices, processors, and power semiconductors, contribute to rapid market expansion.

Asia Pacific is expected to generate the highest demand during the forecast period in the Injectors for Diffusion Lpcvd market. This growth is primarily driven by the concentration of semiconductor manufacturing hubs in countries like Taiwan, South Korea, China, and Japan, which are significant producers and consumers of these materials. The region's dominance is further supported by rapid industrialization, increasing adoption of advanced semiconductor technologies, and the rising demand for high-performance electronic devices.

Top 5 Trends in Injectors for Diffusion Lpcvd Market

1. Increasing Demand from Semiconductor Industry

The semiconductor industry is the primary driver for injectors in diffusion LPCVD systems, used for depositing high-quality thin films in chip manufacturing. Rising demand for advanced integrated circuits, memory devices, and power semiconductors is fueling adoption. Manufacturers require precise, uniform gas distribution to ensure film quality, reproducibility, and wafer yield. With the expansion of semiconductor fabrication facilities globally, particularly for next-generation nodes, LPCVD injectors are crucial for high-volume production. Companies are investing in optimized injector designs to meet the needs of miniaturized and complex semiconductor devices, enhancing performance and reliability.

2. Advancements in Injector Design and Materials

Innovations in injector geometry, flow dynamics, and corrosion-resistant materials are transforming the LPCVD market. Modern injectors offer uniform gas distribution, reduced particle contamination, and improved thermal stability, enhancing thin-film quality and process consistency. Materials such as high-purity stainless steel, quartz, and specialty alloys extend injector lifespan in harsh LPCVD environments. These advancements support precise control of deposition rates and conformality in high-aspect-ratio structures. Manufacturers are increasingly adopting modular and customizable injector designs, allowing integration into diverse LPCVD systems and processes. The trend emphasizes reliability, process efficiency, and scalability in semiconductor and MEMS fabrication.

3. Miniaturization and High-Density Device Fabrication

As semiconductor and MEMS devices become smaller and more complex, injectors for diffusion LPCVD must provide uniform thin-film deposition across high-density wafer surfaces. Miniaturization demands precise gas flow management and temperature control to ensure consistent layer thickness and material properties. LPCVD injectors are being optimized for multi-wafer processing and high-throughput applications. The trend supports advanced nodes in IC manufacturing, microelectromechanical systems, and photonics. Manufacturers are developing injectors with enhanced flow uniformity, reduced particle generation, and compatibility with complex wafer geometries, enabling high-quality production of increasingly compact, high-performance electronic components.

4. Focus on Process Efficiency and Energy Optimization

Efficiency improvements are a major trend in LPCVD injector development. Companies are designing injectors that minimize gas waste, reduce thermal energy consumption, and accelerate deposition processes without compromising film quality. Optimized gas flow and uniform deposition enhance yield and reduce operational costs. Advanced injectors enable shorter cycle times, lower furnace temperatures, and precise chemical utilization, aligning with sustainability initiatives. Semiconductor fabs benefit from lower energy consumption and reduced environmental footprint. The focus on energy-efficient, high-performance injectors is driven by cost pressures, regulatory standards, and the growing need for environmentally responsible manufacturing processes in the electronics and MEMS industries.

5. Integration with Automation and Industry 4.0 Technologies

Modern semiconductor manufacturing increasingly relies on automated processes and real-time monitoring. LPCVD injectors are being integrated with sensors, feedback systems, and automated control for precise gas flow, deposition uniformity, and process reproducibility. Industry 4.0 adoption allows predictive maintenance, reducing downtime and extending injector lifespan. Data-driven process optimization improves yield and supports high-volume production of advanced semiconductor and MEMS devices. Integration with smart manufacturing systems enhances traceability, process stability, and energy efficiency. This trend emphasizes combining hardware innovation with digital technologies to deliver reliable, high-throughput, and sustainable thin-film deposition solutions in next-generation semiconductor fabrication.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Injectors for Diffusion Lpcvd market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the Injectors for Diffusion Lpcvd Market

- Tokyo Electron Limited

- Applied Materials, Inc.

- Lam Research Corporation

- ASM International N.V.

- Kokusai Electric Corporation

- Hitachi High-Technologies Corporation

- Eugene Technology Co., Ltd.

- CVD Equipment Corporation

- Centrotherm International AG

- Thermco Systems

- Tempress Systems, Inc.

- Jusung Engineering Co., Ltd.

- PVA TePla AG

- SierraTherm Production Furnaces Inc.

- SCHMID Group

- Singulus Technologies AG

- Planar Semiconductor, Inc.

- SVCS Process Innovation

- SEMCO Technologies

- AIXTRON SE

1. Tokyo Electron Limited

Headquarters: Tokyo, Japan

Tokyo Electron Limited (TEL) is a leading Japanese semiconductor equipment manufacturer, specializing in deposition, etching, and cleaning systems for wafer fabrication. The company provides advanced injectors for diffusion LPCVD, ensuring precise gas distribution, uniform thin-film deposition, and high process reliability. TEL serves global semiconductor fabs, offering solutions for memory, logic, and power devices. With strong R&D capabilities, innovative equipment design, and a focus on yield enhancement, TEL supports miniaturization, high-density circuits, and next-generation semiconductor nodes. Its commitment to sustainability, automation, and quality positions it as a key player in LPCVD injector technology.

2. Applied Materials, Inc.

Headquarters: Santa Clara, USA

Applied Materials is a major American semiconductor equipment company, providing solutions for deposition, etching, and wafer processing. Its diffusion LPCVD injectors are engineered for uniform film deposition, high throughput, and process reproducibility in semiconductor and MEMS manufacturing. Applied Materials serves leading global fabs, supporting advanced node ICs, power devices, and sensor technologies. With continuous innovation, robust R&D, and Industry 4.0 integration, the company enhances wafer yield, energy efficiency, and process stability. Its global presence, technical expertise, and focus on automation make Applied Materials a trusted partner for LPCVD solutions in high-performance, next-generation semiconductor production.

3. Lam Research Corporation

Headquarters: Fremont, USA

Lam Research Corporation is a leading American supplier of wafer fabrication equipment, including LPCVD systems and precision injectors for thin-film deposition. The company’s injectors provide uniform gas flow, thermal stability, and reduced particle contamination, supporting advanced semiconductor nodes and high-density circuits. Lam Research serves global semiconductor manufacturers, enabling high yield and consistent wafer quality. Its focus on R&D, automation, and process optimization drives innovations in deposition, etching, and surface engineering. By integrating smart manufacturing and energy-efficient solutions, Lam Research helps clients achieve scalable, high-performance semiconductor production, making it a key contributor to the diffusion LPCVD injector market worldwide.

4. ASM International N.V.

Headquarters: Almere, Netherlands

ASM International N.V. is a Dutch semiconductor equipment company specializing in deposition technologies, including LPCVD and ALD systems. The company designs high-precision injectors for diffusion LPCVD, delivering uniform thin films, high process control, and enhanced wafer yield. ASM serves advanced logic, memory, and power device manufacturers, supporting next-generation semiconductor nodes. With strong R&D, global manufacturing, and collaboration with fabs, ASM emphasizes automation, energy efficiency, and sustainability. Its innovative injector designs ensure reproducibility and reliability in complex processes. ASM International’s focus on high-performance materials and precision engineering positions it as a leading provider in the global LPCVD injector market.

5. Kokusai Electric Corporation

Headquarters: Tokyo, Japan

Kokusai Electric Corporation is a Japanese company providing advanced semiconductor equipment and precision injectors for LPCVD processes. Its solutions are used in thin-film deposition for semiconductors, MEMS, and optoelectronic devices, ensuring uniform gas distribution, thermal stability, and high-quality wafer output. Kokusai Electric emphasizes innovation in equipment design, process control, and high-density semiconductor manufacturing. The company serves global semiconductor fabs, supporting next-generation nodes, energy-efficient processes, and automation integration. With expertise in precision engineering, R&D, and sustainable manufacturing, Kokusai Electric is recognized for delivering reliable LPCVD injector solutions that enhance yield, performance, and process reproducibility in advanced semiconductor fabrication.

Are you ready to discover more about the Injectors for Diffusion Lpcvd market?

The report provides an in-depth analysis of the leading companies operating in the global Injectors for Diffusion Lpcvd market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Tokyo Electron Limited.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- Applied Materials, Inc.

- Lam Research Corporation

- ASM International N.V.

- Kokusai Electric Corporation

- Hitachi High-Technologies Corporation

- Eugene Technology Co., Ltd.

- CVD Equipment Corporation

- Centrotherm International AG

- Thermco Systems

Conclusion

The Injectors for Diffusion LPCVD Market Size is poised for significant growth, driven by increasing demand for high-performance semiconductor devices, MEMS, and advanced microelectronics. Key trends such as innovations in injector design, miniaturization, energy-efficient deposition, and integration with Industry 4.0 technologies are shaping market dynamics. Leading players are focusing on R&D, automation, and sustainable manufacturing to meet evolving industry requirements. With expanding semiconductor fabrication globally and rising adoption of precise, high-throughput LPCVD systems, the market offers opportunities for technological advancement, enhanced wafer yield, and reliable thin-film deposition. Continued innovation and strategic investments will define the market’s future trajectory.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?