World's Top 40 Companies in High Temperature Adhesives in 2025 Watch List: Statistics Report (2024–2035).

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

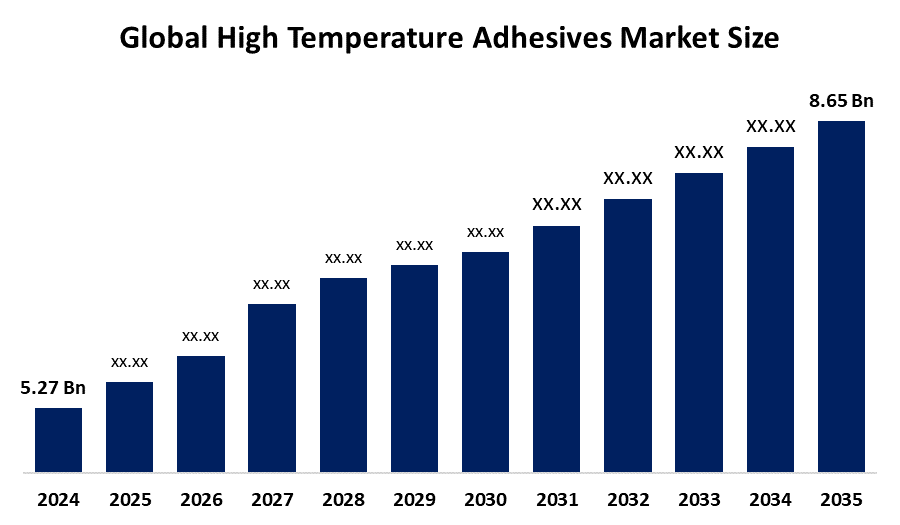

According to a research report published by Spherical Insights & Consulting, The Global High Temperature Adhesives Market Size is projected Grow from USD 5.27 Billion in 2024 to USD 8.65 Billion by 2035, at a CAGR of 4.61 % during the forecast period 2025–2035. The High Temperature Adhesives market offers future opportunities in aerospace, automotive, and electronics, driven by rising demand for lightweight materials, electric vehicles, renewable energy, and advanced manufacturing requiring durable bonding solutions under extreme conditions.

Introduction

The High Temperature Adhesives Market Size is emerging as a critical segment in advanced materials, offering superior bonding performance under extreme heat and harsh environments. These adhesives are designed to withstand temperatures exceeding 200°C, making them vital for industries such as aerospace, automotive, electronics, energy, and construction. They provide strong adhesion, thermal stability, and chemical resistance, enabling lightweight structures and advanced designs. With increasing demand for electric vehicles, renewable energy technologies, and miniaturized electronic components, the market is experiencing strong growth. Continuous R&D efforts, sustainability-driven formulations, and expanding industrial applications are expected to further drive innovation and adoption in this market.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the High Temperature Adhesives market.

High Temperature Adhesives Market Size & Statistics

- The Market Size for High Temperature Adhesives Was Estimated to be Worth USD 5.27 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 4.61 % Between 2025 and 2035.

- The Global High Temperature Adhesives Market Size is Anticipated to Reach USD 8.65 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the High Temperature Adhesives market.

- North America is expected to grow the fastest during the forecast period in the High Temperature Adhesives market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the High Temperature Adhesives market. The Asia Pacific region leads demand for high temperature adhesives due to its booming automotive, aerospace, and electronics industries, coupled with rapid industrial expansion, rising infrastructure projects, and strong government support for advanced manufacturing and renewable energy technologies.

North America is expected to generate the highest demand during the forecast period in the High Temperature Adhesives market. North America’s rapid growth in the High Temperature Adhesives market is fueled by rising demand in aerospace, automotive, and electronics industries, coupled with strong R&D investments, advanced manufacturing capabilities, and emphasis on high-performance, heat-resistant bonding solutions.

Top 5 Trends in High Temperature Adhesives Market

1. Growing Demand from Aerospace and Defense

The aerospace and defense industry is a key driver for high temperature adhesives, where performance under extreme conditions is critical. Adhesives are widely used in engines, structural bonding, heat shields, and composite materials. They offer benefits such as weight reduction, thermal resistance, and durability in harsh environments. With rising aircraft production, space exploration programs, and defense modernization projects worldwide, demand is surging. Moreover, regulatory requirements for fuel efficiency and emission reduction encourage the use of lightweight materials bonded with high-performance adhesives. This trend is creating opportunities for adhesive manufacturers to provide innovative, reliable solutions tailored to aerospace-grade specifications.

2. Expansion in Automotive and Electric Vehicles (EVs)

High temperature adhesives are gaining traction in the automotive sector, particularly in electric vehicles. They are used in battery assembly, powertrain systems, exhaust systems, and components exposed to high heat. Adhesives help enhance safety, efficiency, and thermal management in EV batteries, which is vital for performance and longevity. With the global shift toward sustainable mobility and stricter emission norms, automakers are increasingly adopting lightweight materials bonded with heat-resistant adhesives. As EV production rises, adhesives with thermal conductivity, high strength, and chemical resistance are in demand, making this segment one of the fastest-growing markets for high temperature adhesive applications.

3. Rising Applications in Electronics and Semiconductors

The electronics and semiconductor industries rely heavily on high temperature adhesives for circuit assembly, semiconductor packaging, and thermal management. These adhesives ensure reliability in devices exposed to heat generated by advanced microprocessors, 5G infrastructure, and high-performance computing systems. Adhesives also play a key role in miniaturization, offering strong bonding without compromising performance. With the rapid expansion of consumer electronics, IoT, and advanced communication technologies, demand is increasing. Additionally, the semiconductor industry’s global growth, supported by government investments and rising chip demand, is fueling adoption. This trend highlights adhesives’ critical role in improving durability, heat dissipation, and long-term device efficiency.

4. Increased Use in Industrial Equipment and Energy Sector

Industrial equipment and the energy sector are emerging as major consumers of high temperature adhesives. Applications include turbines, boilers, heat exchangers, and solar panels, where adhesives must withstand intense thermal cycles and harsh conditions. The shift toward renewable energy, including wind and solar, further increases demand for durable bonding solutions capable of resisting high temperatures and environmental stress. Adhesives are also critical in oil and gas equipment and power plants to ensure operational reliability and safety. With industries prioritizing energy efficiency and performance, the need for innovative, high-performance adhesives is expanding, opening strong opportunities for specialized adhesive solutions.

5. Innovation in Eco-Friendly and Advanced Formulations

Sustainability is becoming a major focus in the adhesives industry, driving innovation in eco-friendly high temperature adhesives. Manufacturers are developing solvent-free, water-based, and bio-based formulations to reduce environmental impact while meeting stringent regulatory standards. At the same time, advancements in material science are producing adhesives with superior thermal stability, chemical resistance, and durability. Hybrid technologies such as nanomaterial integration and ceramic-based adhesives are expanding performance capabilities, supporting applications in aerospace, electronics, and automotive. This dual push for sustainability and high performance is transforming the market, positioning advanced adhesive technologies as essential components in future industrial and clean energy systems.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the High Temperature Adhesives market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 9 Companies Leading the High Temperature Adhesives Market

- 3M Company

- Dow Corning

- Cyberbond LLC

- Three Bond Co. Ltd.

- Master Bond Inc.

- Henkel AG

- Delo Industrial Adhesives LLC

- Permabond LLC

- Cotronics Corporation

1. 3M Company

Headquarters: Saint Paul, Minnesota, U.S.

3M Company is a globally diversified technology and innovation leader, offering a wide portfolio of products across adhesives, abrasives, healthcare, consumer goods, and electronics. In the high-temperature adhesives market, 3M is renowned for its advanced bonding solutions that provide durability, heat resistance, and reliability in aerospace, automotive, and industrial applications. With a strong focus on R&D, the company continually introduces next-generation adhesives that meet stringent safety and performance standards. 3M’s commitment to sustainability, customer-centric innovation, and global presence in over 70 countries strengthens its position as one of the top players in the specialty adhesives industry.

2. Dow Corning

Headquarters: Midland, Michigan, U.S.

Dow Corning, now fully integrated into Dow Inc., is a global leader in silicone-based products and advanced materials, including high-performance adhesives and sealants. The company’s high-temperature adhesives are widely utilized in industries such as electronics, aerospace, automotive, and construction for their exceptional thermal stability and durability. Dow Corning focuses heavily on sustainability and energy efficiency, offering solutions that extend product life and improve performance in extreme conditions. With a legacy of innovation spanning decades, the company leverages strong R&D capabilities, a global distribution network, and collaborations with industrial leaders to remain a trusted name in high-performance adhesive technologies worldwide.

3. Cyberbond LLC

Headquarters: Batavia, Illinois, U.S.

Cyberbond LLC is a specialty adhesives manufacturer known for producing high-quality, high-performance adhesives for industrial and commercial applications. Its product portfolio includes instant adhesives, UV-curing adhesives, and high-temperature adhesives designed to withstand extreme conditions. Cyberbond serves sectors such as automotive, electronics, medical devices, and general manufacturing, delivering solutions that enhance efficiency and reliability. The company’s high-temperature adhesives are valued for their strong bonding strength, durability, and adaptability in challenging environments. Cyberbond emphasizes customer-focused innovation, quality assurance, and flexibility, making it a preferred partner for businesses seeking precision-engineered adhesive solutions that meet rigorous industry demands.

4. Three Bond Co. Ltd.

Headquarters: Tokyo, Japan

Three Bond Co. Ltd. is a global manufacturer of adhesives, sealants, and coatings, with a strong reputation for developing innovative bonding solutions. The company’s high-temperature adhesives are extensively used in automotive, electronics, aerospace, and machinery sectors, ensuring reliable performance under extreme heat and pressure. Three Bond’s advanced formulations are engineered to provide durability, chemical resistance, and energy efficiency. With a strong presence across Asia, Europe, and North America, the company emphasizes R&D and customization to meet specific client needs. Three Bond’s continuous innovation and commitment to sustainable practices have established it as a leading provider of specialty adhesives worldwide.

5. Master Bond Inc.

Headquarters: Hackensack, New Jersey, U.S.

Master Bond Inc. is a leading manufacturer of advanced adhesives, sealants, coatings, and encapsulants tailored for high-performance industries. Its high-temperature adhesives are specifically designed to deliver exceptional bonding strength, chemical resistance, and durability in aerospace, automotive, electronics, and oil and gas applications. Known for its customer-focused approach, Master Bond develops customized solutions that meet unique client requirements while adhering to strict quality standards. The company is widely recognized for its expertise in epoxy, silicone, and polyurethane technologies. With decades of experience, Master Bond has earned a reputation for providing reliable, innovative adhesive solutions that perform in the most demanding environments.

Are you ready to discover more about the High Temperature Adhesives market?

The report provides an in-depth analysis of the leading companies operating in the global High Temperature Adhesives market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- 3M Company.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- Dow Corning

- Cyberbond LLC

- Three Bond Co. Ltd.

- Master Bond Inc.

- Henkel AG

- Delo Industrial Adhesives LLC

- Permabond LLC

- Cotronics Corporation

Conclusion

The High Temperature Adhesives market is poised for steady growth as industries increasingly demand durable, reliable bonding solutions capable of withstanding extreme heat and harsh environments. Rising adoption across aerospace, automotive, electronics, and renewable energy highlights the material’s importance in driving efficiency, safety, and innovation. With strong opportunities in electric vehicles, semiconductors, and industrial equipment, the market is expected to benefit from ongoing R&D and sustainability-driven formulations. Companies focusing on advanced technologies, eco-friendly solutions, and customized offerings will gain a competitive edge. As global manufacturing evolves, high temperature adhesives will remain integral to supporting next-generation applications and long-term industrial progress.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?