Top 50 Global Companies in Metal Stamping Market 2025: Strategic Overview And Future Trends (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

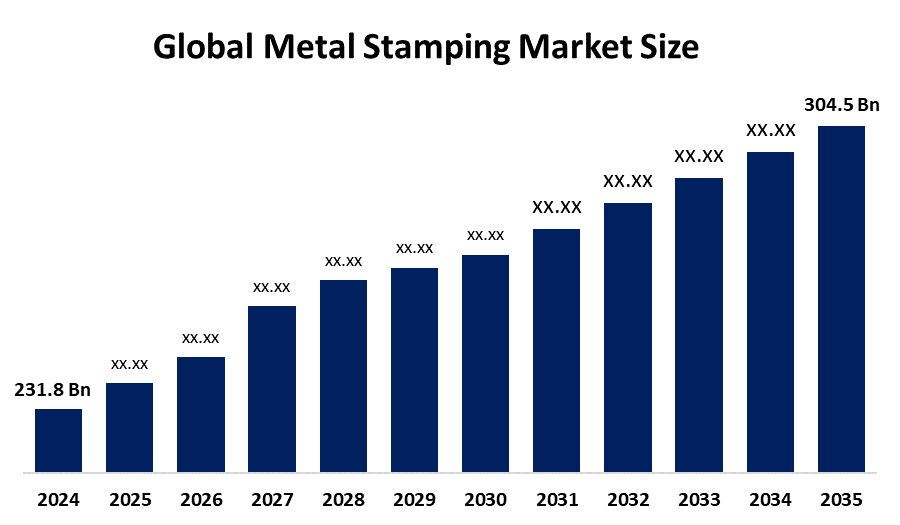

According to a research report published by Spherical Insights & Consulting, The Global Metal Stamping Market Size is projected to Grow from USD 231.8 Billion in 2024 to USD 304.5 Billion by 2035, at a CAGR of 2.51% during the forecast period 2025–2035. The market for metal stamping is in greater demand as driven by the demand for lightweight components and an increase in vehicle production. Stamping operations are becoming more accurate and efficient due to technological developments, including the incorporation of automation, robotics, and artificial intelligence. Additionally, the requirement for stamped metal parts like aluminium frames and brackets is rising as a result of the increased demand for renewable energy technologies like solar and wind power.

Introduction

Metal stamping is a manufacturing process that involves shaping flat sheet metal into specific forms using dies and a stamping press. A stamping press and dies are used in the manufacturing process of metal stamping, which shapes flat sheet metal into predetermined shapes. Poking, blanking, bending, flanging, embossing, and coining are some of the processes that are included in this cold-forming method. Initially, a metal sheet is inserted into a die, where a punch exerts force to shape the metal into the required shape. Many industries, including automotive, aerospace, electronics, and appliances, use metal stamping because of its effectiveness and capacity to mass-produce high-precision parts. Its cost-effectiveness, rapidity, and consistency in creating intricate geometries and precise tolerances make the process highly regarded.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Metal Stamping Market.

Metal Stamping Market Size & Statistics

- The Market Size for Metal Stamping Was Estimated to be worth USD 231.8 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 2.51% between 2025 and 2035.

- The Global Metal Stamping Market Size is anticipated to reach USD 304.5 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Metal Stamping Market

- North America is expected to grow the fastest during the forecast period in the Metal Stamping Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the metal stamping market. The market for metal stamping is now growing in North America due to the rising demand for lightweight automobiles. Advanced materials like aluminium and high-strength steels are being used by automakers to lighten their vehicles in order to improve fuel economy and comply with strict environmental standards. The manufacturing of electric vehicles, which need specialised stamped components like battery enclosures and chassis pieces, is one area where this trend towards lightweighting is very noticeable. North America is positioned as a major participant in the global automotive metal stamping market thanks to its well-established automotive manufacturing base and continuous investments in cutting-edge stamping technology.

Asia Pacific is expected to generate the highest demand during the forecast period in the metal stamping market. The metal stamping market with the quickest rate of growth throughout the study period is anticipated to be in the Asia Pacific, due to the demand for cars and consumer gadgets is rising dramatically in emerging economies like China, India, Bangladesh, Indonesia, and Pakistan due to their rapid industrialisation and urbanisation. Precision-stamped components are necessary for the growing production and usage of smartphones and other electronic gadgets in these nations. Furthermore, the defence industry's infrastructure growth and development are increasing demand for machinery and equipment, which in turn is raising the demand for metal stamping services.

Top 10 trends in the Metal Stamping Market

- Automation and Robotics Integration

- Shift Towards Lightweight Materials

- Customization and Flexible Manufacturing

- Integration of Industry 4.0 Technologies

- Sustainability and Recycling Initiatives

- Advancements in Stamping Tools and Techniques

- Globalization and Diversification of Supply Chains

- Adoption of Smart Manufacturing Practices

- Investment in Precision Forging

- 10. Utilization of 3D Printing for Casting Molds

1. Automation and Robotics Integration

The combination of automation and robotics is transforming the metal stamping sector by improving productivity, accuracy, and security. In order to drastically cut cycle times and labour costs, robotic arms and automated systems are being used more and more to perform operations like material loading, part transfer, and quality inspection. Additionally, becoming more popular are collaborative robots, or cobots, which operate alongside human operators to increase throughput and flexibility while preserving a secure working environment. Real-time monitoring and quality control are made possible by sophisticated sensors and visual systems, guaranteeing constant product standards. Data-driven decision-making and predictive maintenance are also made easier by automation, which results in less downtime and better production procedures. This trend is especially noticeable in industries like aerospace and automotive, where strict quality standards and enormous production volumes are critical.

2. Shift Towards Lightweight Materials

The automobile, aerospace, and electronics industries are undergoing considerable change as a result of metal stamping's shift towards lighter materials. Advanced high-strength steels, magnesium, and aluminium are among the materials that are being used more and more to lighten components without sacrificing strength or safety. The demand for increased performance, fuel efficiency, and adherence to strict environmental standards is what is driving this shift. Lightweight materials help reduce vehicle weight in the automobile industry, which improves fuel efficiency and lowers pollutants. Similar to this, using lightweight alloys in aerospace improves cargo capacity and fuel economy by lowering aircraft weight. The trend also applies to consumer electronics, where the development of robust and portable products is made easier by lightweight materials.

3. Customization and Flexible Manufacturing

Personalisation and Adaptability because of the increasing need for customised components, manufacturing in the metal stamping industry is becoming a major trend. Stamping capabilities that accommodate a variety of applications from distinct design aspects to different material kinds and batch volumes are becoming more and more available from manufacturers. Techniques like sophisticated simulation software, modular tooling, and adaptable procedures that enable quick switchovers and design modifications are examples of how flexibility is accomplished. The demand for customised parts in sectors including consumer electronics, appliances, automobiles, and aerospace is being driven by real-time client feedback. Additionally, businesses are able to react swiftly to changing consumer tastes and market trends without sacrificing quality due to smaller batch production, on-demand fabrication, and design flexibility.

4. Integration of Industry 4.0 Technologies

Real-time data analysis, smart sensors, and interconnected systems are being incorporated into production workflows by the Integration of Industry 4.0 Technologies movement, which is drastically changing the metal stamping sector. Stamping presses equipped with Internet of Things sensors allow for constant monitoring of ambient conditions and machine performance, facilitating condition-based maintenance to save downtime. These days, AI-driven control loops and predictive analytics are used with automated systems to optimise material flows and process parameters for increased accuracy and consistency. Engineers can find flaws, test tooling modifications, and improve designs prior to physical implementation by using digital twins and simulation tools to visually mimic stamping operations. All of these advances combined are increasing productivity, decreasing error rates, and empowering businesses to swiftly and effectively meet market demands.

5. Sustainability and Recycling Initiatives

The metal stamping industry's Sustainability & Recycling Initiatives trend is focused on reducing environmental impact and optimising resource utilisation. Important procedures include waste reduction and material recycling, which involve gathering, sorting, and reusing scrap metal from stamping operations to lessen reliance on fresh raw materials. To cut down on overall energy use, energy-efficient production techniques are also used, such as stamping presses that use less power and better facility lighting and climate control systems. Businesses are assessing the sustainability of their supply chains and placing a strong emphasis on buying from vendors who follow environmentally friendly procedures. Another element is switching out dangerous chemicals used for cooling or lubricating with safer alternatives for the environment, such as non-toxic or biobased replacements.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the metal stamping market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 22 Companies Leading the Metal Stamping Market

- Arconic

- ACRO Building Systems

- Manor Tool & Manufacturing Company

- LINDY MANUFACTURING CO

- D&H Industries, Inc.

- Kenmode, Inc.

- Klesk Metal Stamping Co.

- Aro Metal Stamping Company, Inc.

- Tempco Manufacturing Company, Inc.

- Interplex Holdings Pte. Ltd.

- Caparo Group.

- Goshen Stamping Company

- Clow Stamping Company

- American Industrial Co.

- Martinrea International Inc.

- Magna International Inc.

- Hayes Lemmerz International

- Harvey Vogel Manufacturing Co.

- Ningbo Haitong Metal Fabrication Co, LTD.

- Dongguan Fortuna Metal & Electronics Co., Ltd

- thyssenkrupp AG

- Alcoa Corporation

- Others

1. Arconic

Headquarters: Pennsylvania, USA

Building & Construction Systems, Extrusions, and Rolled Products are the company's business segments. Aluminium sheets and plates are supplied by Rolled Products for use in industrial settings, automotive bodywork, packaging, and aerospace components. Under trademarks including Kawneer and Reynobond, the Building & Construction business provides building envelope solutions, including windows, curtain walls, façades, and architectural panels. Arconic supports efforts across various industries to create lighter, more efficient, and greener structures by fusing innovative design with high-performance materials.

2. ACRO Building Systems

Headquarters: Wisconsin, USA

Acro Building Systems is a U.S. manufacturer specialising in safety devices and products for roofing and fall protection. Their product line comprises wall scaffolding systems, guardrail systems, scaffolding accessories, fixed and adjustable roof brackets, and other equipment for both residential and commercial roofing applications. Their ISO 9001 factory in Milwaukee, Wisconsin, produces all of their goods in the United States. The pieces are hand-welded and powder-coated in safety yellow. The business places a strong emphasis on alternative fall safety options, OSHA compliance, and job site usability and installation.

3. MANOR TOOL & MANUFACTURING COMPANY

Headquarters: Illinois, USA

Manor Tool & Manufacturing Company is a deep-draw fabrication and precision metal stamping expert with its headquarters located in Schiller Park, Illinois, USA. The company uses turret presses, sophisticated progressive dies, and tooling skills to produce high-volume, short-run, and custom prototype metal parts. In addition to stamping, they also offer deep drawing, machining, finishing, bespoke tooling design, and secondary processes, including assembling and deburring. As an ISO-certified company that serves a variety of industries, including consumer goods, electronics, medical devices, automotive, and aerospace, Manor places a high value on accuracy and quality.

4. LINDY MANUFACTURING CO

Headquarters: Illinois, USA

The metal stamping business, Lindy Manufacturing Co., is situated in Downers Grove, Illinois, in the United States. With a focus on stamped metal components, it works in the manufactured metal products industry. The business provides precise metal stamping services, managing small-volume manufacturing as well as custom and prototype tasks. To deliver completed stamped components, they might perform secondary processes like bending and shaping. To guarantee that stamping solutions fulfil necessary performance and durability standards, Lindy Manufacturing places a strong emphasis on quality, prompt delivery, and close client collaboration.

5. D&H Industries, Inc.

Headquarters: Wisconsin, USA

The precision metal stamping and fabrication business D&H Industries, Inc. is situated in Oconomowoc, Wisconsin, in the United States. With a focus on deep-draw and progressive stamping, the company works with a variety of high-strength alloys, cold-rolled steel, stainless steel, copper, brass, and aluminium. In order to support both basic and complicated patterns, its material thickness ranges from extremely thin gauge to significant thicknesses. In addition to stamping, D&H provides a broad range of fabrication services, including CNC machining, robotic welding, MIG, TIG, resistance welding, countersinking, drilling, deburring, hardware insertion, and assembly.

Are you ready to discover more about the metal stamping market?

The report provides an in-depth analysis of the leading companies operating in the global metal stamping market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Arconic

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- ACRO Building Systems

- MANOR TOOL & MANUFACTURING COMPANY

- LINDY MANUFACTURING CO

- D&H Industries, Inc.

- Kenmode, Inc.

- Klesk Metal Stamping Co.

- Aro Metal Stamping Company, Inc.

- Tempco Manufacturing Company, Inc.

- Interplex Holdings Pte. Ltd.

- Caparo Group.

- Goshen Stamping Company

- Clow Stamping Company

- American Industrial Co.

- Martinrea International Inc.

- Magna International Inc.

- Hayes Lemmerz International

- Harvey Vogel Manufacturing Co.

- Ningbo Haitong Metal Fabrication Co, LTD.

- Dongguan Fortuna Metal & Electronics Co., Ltd

- thyssenkrupp AG

- Alcoa Corporation

- Others

Conclusion

The metal stamping market is accelerating because of its conductivity, tolerance, corrosion resistance, and polish. Metal stamping for frames, chassis, lens holders, and antennas is becoming more and more popular in electronics, including smartphones, controllers, and headphones. The growing number of unique mobile subscribers is driving up demand for metal stamping and phone manufacturing. Additionally, the push for renewable energy wind turbines, solar panels, and mounting systems is increasing demand for stamped parts. Therefore, environmental measures and the expansion of electronics are key factors propelling the global metal stamping market.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?