Top 50 Companies in Welding Equipment (2025–2035): Competitive Analysis And Forecast

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

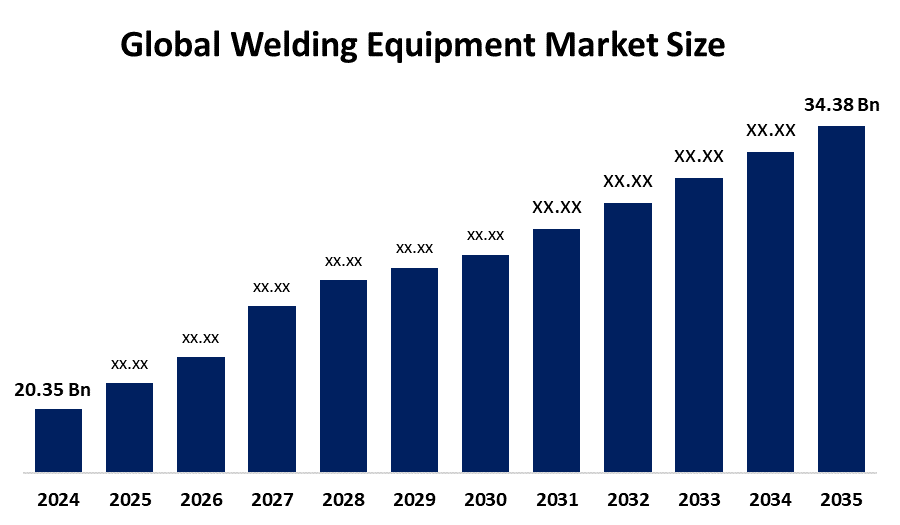

According to a research report published by Spherical Insights & Consulting,The Global Welding Equipment Market Size is projected to Grow from USD 20.35 Billion in 2024 to USD 34.38 Billion by 2035, at a CAGR of 4.88% during the forecast period 2025–2035. The market for welding equipment is in greater demand as the need for sophisticated welding systems and consumables is being driven by an increase in industrial activity in industries including shipbuilding, energy, and infrastructure development. In order to improve productivity and quality compliance, companies are also using automated welding solutions in response to labour shortages and strict regulations.

Introduction

The welding equipment refers to the instruments and apparatus used to fuse materials, usually metals, by generating coalescence. A wide range of instruments and machines necessary for connecting metals and thermoplastics using heat and pressure are included in welding equipment. Creating solid, long-lasting connections between materials is the main goal. Welding equipment, i.e, arc, MIG, and TIG welders, electrodes, filler metals, and protective gear are essential parts. Welding equipment is versatile across a range of sectors and is designed for specialized uses. The choice of electrodes and filler metals is determined by welding procedures and material compatibility. To protect operators from risks including extreme heat and UV rays, safety equipment like as helmets and protective clothes is essential. Selecting and using welding equipment correctly is crucial to the effectiveness and calibre of welding projects, making it a fundamental component of many industries, including manufacturing, construction, and the automotive sector.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Welding Equipment Market.

Welding Equipment Market Size & Statistics

- The Market Size for Welding Equipment Was Estimated to be worth USD 20.35 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 4.88% between 2025 and 2035.

- The Global Welding Equipment Market Size is anticipated to reach USD 34.38 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Welding Equipment Market

- South America is expected to grow significantly during the forecast period in the Welding Equipment Market.

Regional growth and demand

South America is expected to grow significantly during the forecast period in the welding equipment market. The market for welding equipment is now growing in South America due to urbanisation and growing infrastructure developments in industries like manufacturing and construction. Welding is consistently needed in exploration, extraction, and production processes due to the region's robust mining and oil and gas sectors. Initiatives for renewable energy and an increase in the automotive and aerospace industries, which demand sophisticated welding equipment and consumables, provide additional impetus. In the upcoming years, there will likely be a significant increase in demand for welding supplies and equipment in South America.

Asia Pacific is expected to generate the highest demand during the forecast period in the Welding Equipment market. The Welding Equipment market with the quickest rate of growth throughout the study period is anticipated to be in the Asia Pacific. The need for sophisticated welding solutions, such as robotic and automated systems, is being driven by important industries like automotive, shipbuilding, and energy. Favourable laws and government incentives that promote modernisation and manufacturing also help regions. A robust supply chain infrastructure and reduced labour costs further enhance the region's allure. All things considered, Asia Pacific leads the world in welding equipment market share thanks to its extensive industrial base, technological advancements, and massive infrastructure projects.

Top 10 trends in the Welding Equipment Market

- Automation & Robotic Welding

- Digitalization, IoT & Smart Controls

- Advanced Welding Techniques

- Portable and Flexible Equipment

- Sustainability & Energy Efficiency

- Growth Driven by Automotive & Transport Sector

- Resistance Welding Uptake

- Arc Welding Remains Dominant but Hybrid Processes Rise

- Skills & Training Innovations

- Emerging Market Growth & Infrastructure Projects

1. Automation & Robotic Welding

In high-volume manufacturing industries, including heavy machinery, automotive, and aerospace, automation and robotic welding technologies are becoming more and more important. By consistently executing welding settings and pathways, robotic welders reduce faults and rework, offering significantly more precision and repeatability than manual welding. These systems can operate continuously and around the clock, significantly increasing throughput. In order to react in real time to variables like material imperfections or seam misalignment, modern robotic welding also uses adaptive sensors, vision systems, and AI-assisted controls. Safety benefits are also clear; robots can do dangerous welds that include high heat, fumes, or other elements, protecting human workers.

2. Digitalization, IoT & Smart Controls

The welding equipment market is fast changing due to the trends of digitalisation, the Internet of Things, and smart controls. These days, welding machines come with sensors that track temperature, voltage, current, and other important variables continually. Real-time data transmission to cloud or edge systems is made possible by these sensors, enabling live diagnostics, process management, and remote supervision. Predictive maintenance is another advancement; anomalies are identified early to reduce downtime and prevent unplanned failures. In order to maximise weld quality and minimise flaws, smart controls are combining AI, adaptive controllers, and digital twins. Furthermore, by superimposing crucial welding data straight into the field of view, technologies like augmented reality are helping both operators and trainers.

3. Advanced Welding Techniques

Stricter requirements for strength, accuracy, and efficiency are driving the adoption of advanced welding processes. One such technique is Friction Stir Welding, a solid-state technology that welds metals without melting them, improving mechanical integrity and lowering porosity and thermal distortion. Techniques that combine arc and laser beam welding, such as laser hybrid welding, allow for extremely fine control and little heat-affected zones, making them perfect for thin or delicate materials. To combine incompatible metals more consistently, other new methods include electron beam welding, ultrasonics, and specialist solid-state procedures. By lowering energy, pollutants, and waste, these technologies are improving sustainability, increasing material compatibility, improving weld quality, and opening up more intricate design options.

4. Portable and Flexible Equipment

An increasingly important part of contemporary welding operations is portable and adaptable welding equipment. Inverter welder systems, which are typically small, light, and battery-operated, are designed to provide greater mobility in a variety of remote locations where traditional power sources might not be available. Ergonomic designs that prevent fatigue and make transportation easier benefit operators, and multi-process capabilities enable a single machine to perform stick, TIG, or MIG welding as needed. To promote use and dependability, digital interfaces, wireless communication, and enhanced safety features, including overload protection, are also prominently featured. Due to the need for on-site flexibility in industries including construction, field repair, automobile maintenance, and fabrication, there is a growing need for these flexible welding solutions.

5. Sustainability & Energy Efficiency

Energy efficiency and sustainability are emerging as welding technology's top concerns. Inverter-based systems, which use a lot less power and produce less waste heat than conventional transformer-based machines, are being used more and more in modern welding equipment. By reducing distortion and material consumption, low-emission procedures and solid-state welding techniques, including friction stir welding, assist in improving weld quality and lessening their impact on the environment. Consumables are also changing to biodegradable fluxes, recyclable wires, and electrode coatings with lower toxic emissions are becoming more popular. Furthermore, improved heat control, ideal parameter settings, and methods like narrow-gap welding that use less filler material all contribute to energy efficiency. Stricter environmental and regulatory requirements are met, and operations are made cleaner thanks to these advancements.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the welding equipment market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Welding Equipment Market

- Lincoln Electric

- ACRO Automation Systems, Inc.

- AIR LIQUIDE

- Mitco Weld Products Pvt. Ltd.

- Voestalpine Bohler Welding Group GmbH

- Carl Cloos Schweisstechnik GmbH

- OTC DAIHEN Inc.

- Illinois Tool Works Inc.

- Panasonic Industry Co., Ltd.

- Coherent, Inc.

- ESAB

- Polysoude S.A.S.

- Kemppi Oy.

- CRUXWELD

- Miller Electric

- Fronius International

- Others

1. Lincoln Electric

Headquarters: Cleveland, Ohio

Lincoln Electric Holdings, Inc. is a world leader in the design and production of welding goods, such as robotic systems, plasma and oxy-fuel cutting equipment, and arc welding equipment. The corporation, which has its headquarters in Cleveland, Ohio, runs a network of production, sales, and distribution facilities in more than 160 nations. Lincoln Electric has 44 production facilities across the globe and provides services to a range of sectors, including petrochemicals, construction, transportation, and fabrication. The business has a significant presence in both the industrial and consumer industries and is renowned for its innovative welding technology. Lincoln Electric is a well-known brand in welding solutions throughout the world due to its dedication to quality and client satisfaction.

2. ACRO Automation Systems, Inc.

Headquarters: Milwaukee, Wisconsin

One of the leading suppliers of specialised industrial automation solutions is ACRO Automation Systems Inc., which has its main office in Milwaukee, Wisconsin. ACRO, which specialises in automated welding, assembly, and system integration, provides customised machinery made to satisfy the unique requirements of a range of industries, including the production of consumer items, appliances, and automobiles. With a focus on quality and client happiness, the company is renowned for its proficiency in implementing high-performance automation systems. For companies looking for dependable and effective automation solutions, ACRO is a valued partner because of its dedication to innovation and accuracy.

3. AIR LIQUIDE

Headquarters: Paris, France

A worldwide corporation based in France, Air Liquide S.A. specialises in producing and supplying industrial gases and services to a range of industries, including producers of electronics, chemicals, and medical equipment. The corporation has operations in more than 80 countries and its headquarters are in Paris, France. Among the many goods and services that Air Liquide provides are oxygen, nitrogen, hydrogen, and specialty gases in addition to cutting-edge industrial and medical solutions. The business is dedicated to innovation and sustainable development, especially in the areas of artificial intelligence and the energy transition.

4. Mitco Weld Products Pvt. Ltd.

Headquarters: New Delhi, India

A well-known producer with a focus on welding products is Mitco Weld Products Pvt. Ltd., which has its headquarters in New Delhi, India. The business is well known for manufacturing premium brass PVC welding wires for a range of industrial uses. Mitco Weld Products Pvt. Ltd. is a well-known brand in the welding industry with a significant domestic market share. Serving a wide range of clients in many industries has been made possible by the company's dedication to quality and customer satisfaction. Mitco Weld Products Pvt. Ltd., which operates out of its plant in Delhi's Mangolpuri Industrial Area, Phase-II, keeps making a major contribution to India's industrial environment.

5. Voestalpine Bohler Welding Group GmbH

Headquarters: Dusseldorf, Germany

One of the top suppliers of welding supplies, tools, and services worldwide is Voestalpine Böhler Welding Group GmbH, which has its headquarters in Düsseldorf, Germany. The company runs more than 50 subsidiaries in more than 25 countries as a business unit of the Voestalpine AG Metal Engineering Division. Through its specialised brands, Voestalpine Böhler Welding provides a wide range of products, including Fontargen Brazing for brazing and soldering solutions, and Böhler Welding for joint welding and UTP Maintenance for repair and wear protection. Offering premium products and customised solutions to satisfy the unique needs of its global clientele, the company caters to a wide range of industries, including construction, energy, automotive, and aerospace. Excellence in welding technique, sustainability, and innovation are all priorities for Voestalpine Bohler Welding.

Are you ready to discover more about the welding equipment market?

The report provides an in-depth analysis of the leading companies operating in the global welding equipment market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Lincoln Electric

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- ACRO Automation Systems, Inc.

- AIR LIQUIDE

- Mitco Weld Products Pvt. Ltd.

- Voestalpine Bohler Welding Group GmbH

- Carl Cloos Schweisstechnik GmbH

- OTC DAIHEN Inc.

- Illinois Tool Works Inc.

- Panasonic Industry Co., Ltd.

- Coherent, Inc.

- ESAB

- Polysoude S.A.S.

- Kemppi Oy.

- CRUXWELD

- Miller Electric

- Fronius International

- Others

Conclusion

The welding equipment market is accelerating due to the need for welding equipment in infrastructure projects is rising as the global construction industry expands, especially in emerging economies. Further driving market expansion is the automobile industry's requirement for sophisticated welding technologies to join lightweight materials like composites and aluminium. The need for welding solutions is also fuelled by an increase in manufacturing across a number of industries, such as shipbuilding and aerospace.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?