Top 50 Companies in Superalloys Market: Key Insights & Innovations

RELEASE DATE: Aug 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

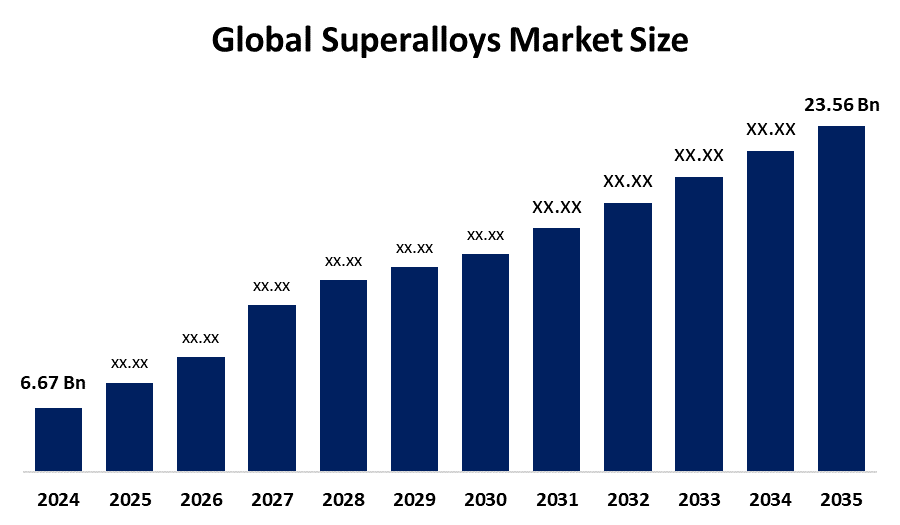

According to a research report published by Spherical Insights & Consulting, The Global Superalloys Market Size is projected to Grow from USD 6.67 Billion in 2024 to USD 23.56 Billion by 2035, at a CAGR of 12.16% during the forecast period 2025–2035. Some of the key factors driving the expansion of the overall market are the constantly developing power generation industries and the increasing use of nickel superalloys in electric and hybrid automobiles. Additionally, significant expenditures and the quickly expanding automotive sector are fueling the market's expansion.

Introduction

Superalloys are complex, high-performance alloys that can withstand high temperatures and oxidizing conditions. They also have great mechanical strength, resistance to corrosion, and resistance to creep at high temperatures. They are often created for uses requiring extreme mechanical strength and constant high surface stability. The majority of the alloy consists of different combinations of Cr, Co, Ni, and Fe, with smaller amounts of Al, Nb, Ta, Mo, and W. The global market for superalloys is experiencing significant expansion. Some of the main drivers propelling the growth of the global market include the quickly expanding aerospace sector, the growing use of superalloys in aircraft gas turbine components, and the rise in demand for gas and oil exploration. Furthermore, the hottest parts of rocket and jet engines, where temperatures can exceed 1200–1400°C, require a variety of these crucial high-temperature materials. At the operating temperature, superalloys maintain their strength, toughness, fatigue resistance, and microstructure stability. They are widely utilized in nuclear reactors, industrial gas turbines, heat exchanger tubing, the chemical processing industry, and submarines because of all these characteristics.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insight - Download the Brochure now and dive deeper into the future of the Superalloys Market.

Superalloys Market Size & Statistics

- The Market Size for Superalloys Was Estimated to be worth USD 6.67 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 12.16% between 2025 and 2035.

- The Global Superalloys Market Size is anticipated to reach USD 23.56 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Superalloys Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Superalloys Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the superalloys market. The growing aerospace, automotive, and energy sectors are anticipated to propel Asia Pacific's growth over the projection period. Superalloys are needed for the high-speed rail, space exploration, and domestic aircraft manufacturing that nations like China, India, and Japan are investing heavily in. China is expanding its aerospace and defense capabilities, which is driving increased demand for cobalt and nickel-based products. With increased manufacturing of hybrid and electric vehicles (EVs), the region also has a thriving automotive sector. Alloys are utilized in battery components and thermal management systems in these vehicles. Furthermore, the Asia Pacific's expanding energy needs are propelling investments in nuclear reactors and sophisticated gas turbines, which will increase the region's product consumption even more.

North America is expected to generate the highest demand during the forecast period in the superalloys market. The region's thriving aerospace and defense sectors, which heavily rely on superalloys for their remarkable strength and resilience to high temperatures, are principally responsible for this dominance. Major defense contractors and aircraft manufacturers like Boeing, Lockheed Martin, and General Electric Aviation are based in the United States, which highlights the region's critical role in generating demand for these high-performance materials.

Top 3 trends in the Superalloys Market

- Increasing adoption of additive manufacturing for superalloy component production

- Emphasis on recycling and sustainability of superalloys

- Advancements in superalloy formulations for improved high-temperature and corrosion resistance

- Rising demand for superalloys in aerospace, automotive, and energy industries

- Investment in research and development for novel superalloy applications

1. Increasing adoption of additive manufacturing for superalloy component production

Increasing adoption of additive manufacturing for superalloy component production is transforming how intricate, high-performance parts are made, reducing material waste and lead times while enabling advanced design flexibility in sectors like aerospace, automotive, and energy.

2. Emphasis on recycling and sustainability of superalloys

Emphasis on recycling and sustainability reflects both industry innovation and regulatory pressure. Advanced recycling methods allow for the recovery and reuse of nickel, cobalt, and chromium alloys, which conserve resources and reduce emissions. This supports circular economy principles and environmental targets.

3. Advancements in superalloy formulations for improved high-temperature and corrosion resistance

Advancements in superalloy formulations for improved high-temperature and corrosion resistance are driving their use in extreme environments such as power plants, jet engines, and energy generation equipment. These innovations extend component lifespan and operational safety, making superalloys indispensable across multiple industries.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the superalloys market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the Superalloys Market

- Allegheny Technologies Incorporated (ATI)

- Precision Castparts Corp. (PCC)

- Haynes International, Inc.

- Carpenter Technology Corporation

- Aperam S.A.

- Special Metals Corporation

- Doncasters Group

- VDM Metals GmbH

- Eramet S.A.

- Cobalt Metals Company

- Nippon Yakin Kogyo Co., Ltd.

- Hitachi Metals, Ltd.

- Outokumpu Oyj

- CRS Holdings Inc.

- Universal Stainless & Alloy Products

- Fushun Special Steel Co., Ltd.

- Superalloy International

- National Alloy Solutions

- Neumo-Ehrenberg Group

- VDM Metals International

- MetalTek International

- Sanyo Special Steel Co., Ltd.

- Arconic Inc.

- VSMPO-AVISMA Corporation

- Changsha Xinkang Advanced Materials Co., Ltd.

1. Allegheny Technologies Incorporated (ATI) – Dallas, Texas, USA

ATI is an industry leader in the Superalloys Market, providing advanced nickel, cobalt, and titanium-based superalloy materials. Headquartered in Dallas, Texas, USA, ATI serves critical sectors such as aerospace, defense, energy, and chemical processing. Its robust global network of manufacturing facilities supports a dependable supply chain and innovation in high-temperature alloys. ATI’s focus on R&D delivers products with exceptional thermal stability and corrosion resistance, meeting the stringent demands of jet engines, gas turbines, and other mission-critical equipment, positioning ATI as a leading force in superalloy advancements.

2. Precision Castparts Corp. (PCC) – Portland, Oregon, USA

Based in Portland, Oregon, USA, Precision Castparts Corp. (PCC) is globally recognized for producing high-performance superalloy castings and forgings. PCC’s materials are widely used in aerospace, power generation, and industrial gas turbines, offering resilience in extreme environments. The company excels in innovation, precision, and quality, thanks to its vertically integrated manufacturing and global supply network. PCC’s superalloy components enable reliable operation at elevated temperatures and pressures, positioning it as a top supplier for OEMs and tier-one customers in demanding markets.

3. Haynes International, Inc. – Kokomo, Indiana, USA

Haynes International, based in Kokomo, Indiana, USA, develops and manufactures corrosion-resistant and high-temperature superalloys for industries like aerospace, chemical processing, and power generation. Renowned for its HASTELLOY® and HAYNES® alloys, the company emphasizes research and technical support for custom solutions. Its commitment to sustainability, product excellence, and worldwide distribution makes Haynes a trusted partner for customers seeking materials capable of enduring aggressive operational conditions, thereby driving market leadership in superalloys.

4. Carpenter Technology Corporation – Philadelphia, Pennsylvania, USA

Carpenter Technology Corporation, headquartered in Philadelphia, Pennsylvania, USA, is a key innovator in specialty superalloys and advanced materials. Serving the aerospace, energy, medical, and transportation sectors, Carpenter develops alloys that withstand extreme environments and facilitate next-generation designs. Their focus on R&D and proprietary manufacturing processes delivers high-performance, fatigue-resistant materials. Carpenter’s expertise in additive manufacturing and process optimization supports growing demand for custom superalloy solutions across global industries.

5. Aperam S.A. – Luxembourg City, Luxembourg

Aperam S.A., headquartered in Luxembourg City, Luxembourg, is a major supplier of stainless steels and superalloys for global markets. With production sites across Europe and Brazil, Aperam delivers high-quality superalloy products tailored for aerospace, automotive, and energy applications. The company distinguishes itself by utilizing sustainable manufacturing practices, including electric arc furnaces and renewable energy. Aperam’s investment in advanced metallurgy, circular economy initiatives, and customer-driven innovation establishes its strong reputation and ongoing leadership in the evolving superalloys market.

Are you ready to discover more about the superalloys market?

The report provides an in-depth analysis of the leading companies operating in the global superalloys market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Allegheny Technologies Incorporated (ATI)

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Precision Castparts Corp. (PCC)

- Haynes International, Inc.

- Carpenter Technology Corporation

- Aperam S.A.

- Special Metals Corporation

- Doncasters Group

- VDM Metals GmbH

- Eramet S.A.

- Others.

Conclusion

The superalloys market is experiencing robust expansion, propelled by rising demand in aerospace, automotive, and energy sectors where high-performance, heat-resistant materials are critical. Innovations in additive manufacturing and alloy formulation are improving efficiency, durability, and corrosion resistance, broadening the market’s applications. Industry leaders are increasingly focused on sustainable manufacturing and recycling alongside investments in R&D for advanced materials. With ongoing technological advancements and a shift toward resource-efficient production, the superalloys market is set for strong growth, providing essential solutions to next-generation engineering challenges.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?