Top 50 Companies in Polypropylene for 3D Printing Market: Key Insights And Innovations

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

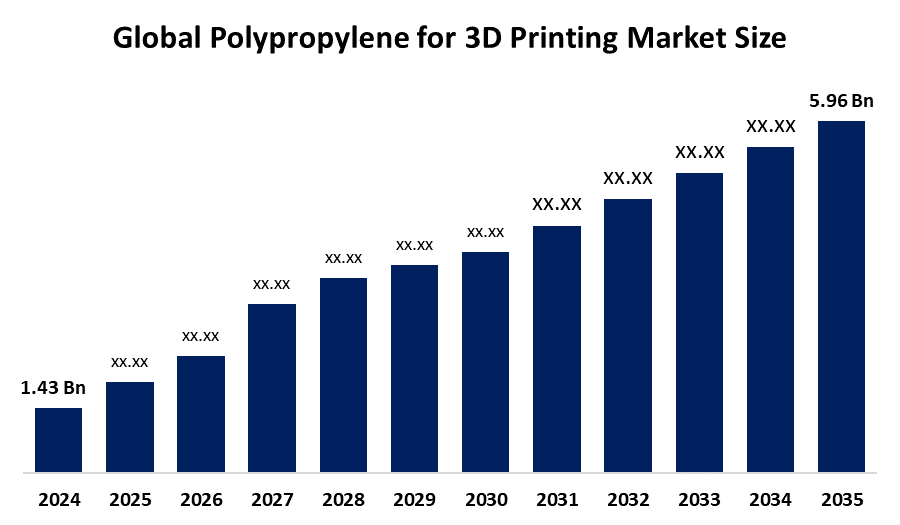

According to a research report published by Spherical Insights & Consulting, The Global Polypropylene for 3D Printing Market Size is projected to Grow from USD 1.43 Billion in 2024 to USD 5.96 Billion by 2035, at a CAGR of 13.86% during the forecast period 2025–2035. One of the main factors propelling the worldwide polypropylene market for 3D printing is the rising need for medical devices made using this technology. Because it is robust, lightweight, and biocompatible, polypropylene is a material that may be used in a variety of ways, including 3D printing.

Introduction

The growing use of 3D printing technology across sectors is driving the market's encouraging growth prospects. The growing need for lightweight, robust materials, cost-effective manufacturing, and quick prototyping in the automotive, aerospace, and healthcare industries is major market driver. Developments in 3D printing methods, such as selective laser sintering (SLS) and fused deposition modeling (FDM), which allow for the accurate creation of intricate shapes, are also driving the market. Furthermore, prospects for 3D printing solutions based on polypropylene are presented by the increased focus on sustainability and the use of environmentally benign materials in manufacturing. The creation of novel polypropylene formulations with enhanced mechanical qualities and printability, as well as the incorporation of machine learning (ML) and artificial intelligence (AI) into 3D printing procedures to maximize production efficiency and minimize material waste, are recent trends.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Polypropylene for 3D Printing Market.

Polypropylene for 3D Printing Market Size & Statistics

- The Market Size for Polypropylene for 3D Printing Was Estimated to be worth USD 1.43 Billion in 2024.

- The Market is Going to Expand at a CAGR of 13.86% between 2025 and 2035.

- The Global Polypropylene for 3D Printing Market Size is anticipated to reach USD 5.96 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Polypropylene for 3D Printing Market.

- Asia-Pacific is expected to grow the fastest during the forecast period in the Polypropylene for 3D Printing Market.

Regional growth and demand

Asia-Pacific is expected to grow the fastest during the forecast period in the polypropylene for 3D printing market. Rapid industrialization, rising use of new manufacturing technologies, and the existence of sizable hubs for the production of consumer products and automobiles are all likely to propel the polypropylene for 3D printing market in the Asia Pacific region. Leading nations in this expansion are China, Japan, and South Korea, thanks to large investments in 3D printing technology and encouraging government programs.

North America is expected to generate the highest demand during the forecast period in the polypropylene for 3D printing market. The market for polypropylene for 3D printing is also growing in North America, which is fueled by the existence of top 3D printing firms, technological developments, and widespread industry usage. A significant contributor to the industry, the US in particular places a high priority on innovation and makes large investments in R&D. Major end consumers of 3D printed polypropylene in North America are the healthcare and aerospace industries, which take advantage of its qualities to create high-performance, bespoke products.

Top 5 trends in the Polypropylene For 3D Printing Market

- Advancements in polypropylene filament formulations

- Growing adoption in automotive and aerospace sectors

- Increased use in healthcare and medical device production

- Expansion of sustainable and recyclable polypropylene options

- Enhanced 3D printer compatibility and printing techniques

1. Advancements in polypropylene filament formulations

Ongoing R&D has led to improved polypropylene filaments featuring enhanced adhesion, reduced warping, and higher mechanical strength. These advancements enable more reliable high-performance 3D printing and open new engineering and industrial applications.

2. Growing adoption in automotive and aerospace sectors

Automotive and aerospace manufacturers are leveraging polypropylene’s lightweight, flexible, and durable properties for custom components, interiors, and prototypes. This trend is reducing costs, optimizing designs, and supporting the shift towards lighter, more fuel-efficient vehicles and aircraft.

3. Increased use in healthcare and medical device production

Polypropylene’s chemical resistance and biocompatibility have fueled its adoption in medical devices, surgical guides, and patient-specific models. 3D printing with polypropylene enables rapid, cost-effective prototyping and manufacturing for personalized healthcare solutions.

4. Expansion of sustainable and recyclable polypropylene options

With rising environmental concerns, the market is seeing more eco-friendly polypropylene filaments and circular recycling initiatives. This supports manufacturers’ sustainability objectives and aligns with regulatory drives for greener 3D printing practices.

5. Enhanced 3D printer compatibility and printing techniques

Broader 3D printer support and improved printing methods—such as adjustments for bed adhesion and extrusion parameters—are making polypropylene easier to process. These advancements are increasing PP’s accessibility for designers and engineers seeking versatile, production-ready materials.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the polypropylene for 3D printing market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the Polypropylene For 3D Printing Market

- HP Inc.

- SABIC

- Covestro AG

- LyondellBasell Industries

- 3D Systems Inc.

- BASF SE

- Stratasys Ltd.

- Arkema Group

- Formlabs Inc.

- Evonik Industries AG

- DSM Additive Manufacturing

- Royal DSM

- Materialise NV

- EOS GmbH

- Ultimaker

- Essentium, Inc.

- Materialise

- Renishaw PLC

- MarkForged Inc.

- Carbon, Inc.

- Desktop Metal Inc.

- ExOne Company

- SLM Solutions

- Nano Dimension

- Zortrax

1. HP Inc. – Palo Alto, California, USA

HP Inc. is a pioneer in additive manufacturing solutions, offering advanced polypropylene materials tailored for 3D printing. With its Multi Jet Fusion (MJF) technology, HP enables fast, precise production of durable and recyclable polypropylene parts used across automotive, healthcare, and consumer goods industries. HP focuses on sustainability, providing eco-friendly polymers that meet rigorous performance standards. The company drives innovation in polypropylene 3D printing by collaborating with partners worldwide, ensuring scalable additive manufacturing solutions that fit varied industrial needs. HP’s extensive R&D and global presence make it a key leader in the polypropylene 3D printing market.

2. SABIC – Riyadh, Saudi Arabia

SABIC is a global leader in high-performance plastics, including polypropylene for 3D printing applications across automotive, aerospace, healthcare, and consumer sectors. The company emphasizes innovation in polypropylene formulations with superior strength, thermal stability, and environmental sustainability. SABIC advances additive manufacturing through partnerships and proprietary technologies, enabling lightweight, durable, and customized components. Its focus on developing recyclable and high-quality polypropylene supports expanding 3D printing adoption globally. SABIC’s strong manufacturing base and cutting-edge R&D facilities position it as a major player in the polypropylene filament and powder market for additive manufacturing.

3. Covestro AG – Leverkusen, Germany

Covestro is a leading polymer manufacturer specializing in high-performance materials for 3D printing, including polypropylene composites. Headquartered in Leverkusen, the company develops sustainable, innovative polymers that combine durability, flexibility, and recyclability. Covestro’s polypropylene 3D printing products support a wide range of applications from automotive parts to consumer goods, leveraging advanced feedstock technologies. The company partners with additive manufacturing innovators to promote circular economy principles while delivering high-quality, eco-conscious materials. Covestro’s global manufacturing footprint and commitment to sustainable product development underline its strength in the polypropylene 3D printing market.

4. LyondellBasell Industries – Houston, Texas, USA

LyondellBasell is among the largest global producers of polypropylene and a key innovator in 3D printing materials. Its Beon3D product family combines advanced polymer technologies tailored for additive manufacturing, enabling complex, lightweight, and high-strength 3D-printed parts. With decades of expertise in polyolefins, LyondellBasell supports the automotive, industrial, and construction markets through sustainable, recyclable polypropylene compounds. The company’s investments in R&D and partnerships with 3D printing solution providers drive rapid adoption of polypropylene materials in additive manufacturing, reinforcing LyondellBasell’s leadership position.

5. 3D Systems Inc. – Rock Hill, South Carolina, USA

3D Systems is a pioneer in 3D printing technology, delivering a comprehensive portfolio of materials, including polypropylene-based polymers designed for additive manufacturing. Headquartered in Rock Hill, 3D Systems offers advanced printers and materials that cater to healthcare, aerospace, and industrial sectors. Their polypropylene solutions provide excellent chemical resistance, durability, and flexibility for prototyping and functional part production. Through ongoing innovation and development, 3D Systems enhances polypropylene printability and performance, solidifying its role in expanding the polypropylene 3D printing market.

Are you ready to discover more about the polypropylene for 3D printing market?

The report provides an in-depth analysis of the leading companies operating in the global polypropylene for 3D printing market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- HP Inc.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- SABIC

- Covestro AG

- LyondellBasell Industries

- 3D Systems Inc.

- BASF SE

- Stratasys Ltd.

- Arkema Group

- Formlabs Inc.

- Others.

Conclusion

The polypropylene for 3D printing market is witnessing significant growth, driven by increasing demand for lightweight, durable, and versatile materials in automotive, aerospace, healthcare, and consumer goods industries. Technological advancements in filament formulation and printing techniques continue to improve polypropylene’s printability and mechanical properties, expanding its application scope. Sustainability is becoming a key focus, with more eco-friendly and recyclable polypropylene materials entering the market to meet environmental regulations and consumer demand.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?