Top 50 Companies in Membrane Separation Materials Market 2025: Strategic Overview And Future Trends (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

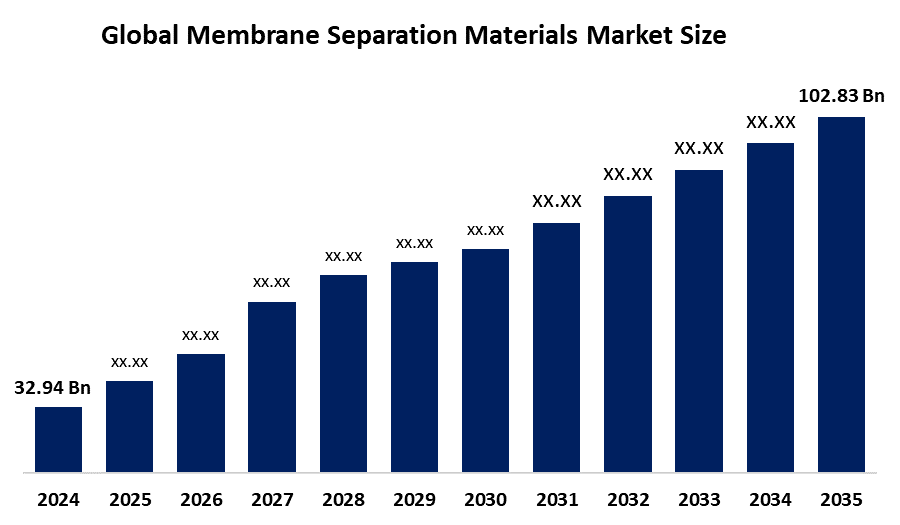

According to a research report published by Spherical Insights & Consulting, The Global Membrane Separation Materials Market Size is projected to grow from USD 32.94 Billion in 2024 to USD 102.83 Billion by 2035, at a CAGR of 10.9% during the forecast period 2025–2035. The market for membrane separation materials in Japan is in greater demand as the necessity for efficient water and wastewater treatment systems has increased due to the growing demand for safe and clean water, as well as the quickening pace of urbanisation and industrialisation. Membrane technologies, such as ultrafiltration and reverse osmosis, provide effective ways to treat industrial effluents and cleanse water.

Introduction

Membrane separation materials are specialty materials made to selectively let some mixture components through while keeping others out. The market for membrane separation materials is expanding rapidly, mostly due to rising demand from the steel and oil, and gas sectors. Membrane separation technologies that use polymeric membranes such as polysulfone, polyacrylonitrile, and polyvinylidene fluoride are used in the steel industry to extract carbon from exhaust gases, improving operating efficiency and environmental compliance. Nanofiltration membranes are also used in the oil and gas industry to treat natural gas, especially coal-bed methane, by lowering reservoir pressure and water content, which makes methane extraction easier. The development of new processing facilities is being driven by the expanding demand for natural gas in industrial and power generation applications, which is increasing the use of membrane separation technologies.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Membrane Separation Materials Market.

Membrane Separation Materials Market Size & Statistics

- The Market Size for Membrane Separation Materials Was Estimated to be worth USD 32.94 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 10.9% between 2025 and 2035.

- The Global Membrane Separation Materials Market Size is anticipated to reach USD 102.83 Billion by 2035.

- The Japan Membrane Separation Materials Market is Growing at a CAGR of 5.38% from 2023 to 2033.

- The Japan Membrane Separation Materials Market Size is Expected to Reach USD 1,893.89 Million by 2033.

- North America Source is expected to generate the highest demand during the forecast period in the Membrane Separation Materials Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Membrane Separation Materials Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the membrane separation materials market. The market for membrane separation materials is now growing in the Asia Pacific due to rising demand from the steel and oil, and gas sectors. Membrane separation technologies that use polymeric membranes such as polysulfone, polyacrylonitrile, and polyvinylidene fluoride are used in the steel industry to extract carbon from exhaust gases, improving operating efficiency and environmental compliance. Nanofiltration membranes are also used in the oil and gas industry to treat natural gas, especially coal-bed methane, by lowering reservoir pressure and water content, which makes methane extraction easier. The development of new processing facilities is being fuelled by the expanding demand for natural gas in industrial and power generation applications, which is increasing the use of membrane separation technologies.

North America Source is expected to generate the highest demand during the forecast period in the membrane separation materials market. The membrane separation materials market with the quickest rate of growth throughout the study period is anticipated to be in North America, due to a number of important factors. One of the main causes is the region's growing need for water treatment solutions as businesses and local governments look for efficient ways to deal with water scarcity and guarantee adherence to strict environmental laws. Furthermore, because membrane separation technologies are efficient and successful in purification procedures, their use is growing in a variety of industries, including biotechnology, pharmaceuticals, and food and beverage. North America is a major player in the global market for membrane separation materials as a result of these variables coming together.

Top 10 trends in the Membrane Separation Materials Market

- Dominance of Polymeric Membranes

- Advancements in Membrane Materials

- Expansion in Food & Beverage Applications

- Growth in Pharmaceutical & Biotech Sectors

- Industrial Wastewater Treatment

- Water & Wastewater Treatment Demand

- Emerging Applications in Lithium Extraction

- Gas Separation Technologies

- Advancements in Desalination Processes

- Stringent Regulatory Compliance

1. Dominance of Polymeric Membranes

The global market for separation materials is dominated by polymeric membranes, especially those composed of polyvinylidene fluoride, polysulfone, and polyethersulfone, because of their affordability, scalability, and adaptability. These membranes are widely employed in many different industries, including the pharmaceutical, food and beverage, and water and wastewater treatment sectors. They are well-liked because of their superior chemical resistance, simplicity in manufacturing, and effectiveness in eliminating impurities from liquids and gases. Their dominance in the market for separation materials is strengthened by ongoing developments in polymer chemistry, which improve these membranes' performance and longevity.

2. Advancements in Membrane Materials

The efficiency and usability of separation methods across a range of sectors are being greatly increased by developments in membrane materials. Novel materials like Thermally Rearranged polymers and Polymers of Intrinsic Microporosity, which have enhanced gas selectivity and permeability and are therefore perfect for uses like carbon capture and hydrogen purification, are being developed by researchers. Additionally, by expanding surface area and promoting selective separation, the use of nanoparticles into mixed-matrix membranes is improving performance. Novel fabrication processes, including as electrospinning and 3D printing, are making it possible to produce membranes with customised architectures, increasing their scalability and fouling resistance. These developments are propelling the creation of membrane separation technologies that are more effective, economical, and environmentally friendly.

3. Expansion in Food & Beverage Applications

The food and beverage industry is using membrane separation technologies more and more because of their effectiveness and capacity to maintain product quality. The separation of whey proteins in dairy processing, the clarity and concentration of fruit juices, and the purifying of drinks like wine and beer are just a few of the uses for these technologies. For example, to improve purity and safety during beer production, yeast and suspended particles are eliminated using ultrafiltration membranes. Furthermore, the concentration of milk and whey made possible by membrane techniques makes it easier to produce cheese and yoghurt. The industry's emphasis on sustainability and quality is in line with the advantages of membrane separation, which include lower energy consumption, less chemical use, and the preservation of nutrients and flavours.

4. Growth in Pharmaceutical & Biotech Sectors

Technologies for membrane separation are becoming more and more essential to the biotechnology and pharmaceutical industries, improving the productivity and quality of drug manufacturing procedures. Protein purification, sterile filtration, and biologic concentration are among the crucial applications that use techniques like ultrafiltration, nanofiltration, and reverse osmosis. In monoclonal antibody purification, for example, sophisticated polyethersulfone membranes have achieved protein recovery rates, which is a notable advancement over conventional techniques. The industry's need for increased yields, scalability, and adherence to strict regulatory standards is what is driving these developments.

5. Industrial Wastewater Treatment

The effectiveness and sustainability of membrane separation methods have made them increasingly important in the treatment of industrial wastewater. Heavy metals, oils, suspended particles, and organic compounds are among the pollutants that are eliminated from industrial effluents using methods including reverse osmosis, ultrafiltration, and microfiltration. With the use of these technologies, enterprises can meet strict environmental laws, recycle water, and minimise discharge amounts. For example, the textile and petrochemical industries use RO membranes to desalinate and purify water. Furthermore, because of their increased permeability and improved fouling resistance, membrane materials including composite membranes and polyvinylidene fluoride have improved performance.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the membrane separation materials market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the Membrane Separation Materials Market

- DuPont de Nemours, Inc.

- Toray Industries, Inc.

- Asahi Kasei Corporation

- BASF SE

- SUEZ Group

- LANXESS AG

- 3M Company

- Pall Corporation (Danaher Corporation)

- Koch Membrane Systems, Inc.

- Merck KGaA

- GEA Group Aktiengesellschaft

- Hyflux Ltd.

- Corning Incorporated

- HUBER SE

- Arkema S.A.

- The Chemours Company

- KUREHA CORPORATION

- DAIKIN INDUSTRIES, Ltd

- Quadrant Group of Companies

- Gujarat Fluorochemicals Ltd

- Others

1. DuPont de Nemours, Inc.

Headquarters: Delaware, USA

Wilmington, Delaware, USA is headquarters to the headquarters of DuPont de Nemours, Inc., a renowned international science and technology corporation. The company's areas of expertise include water filtration, industrial technologies, and electronics. DuPont is widely recognised for its inventive membrane separation material solutions, including cutting-edge filtering technology for water treatment and other uses. Among the segments that make up the company's operations are Mobility & Materials, Electronics & Industrial, and Water & Protection. DuPont is driven to use science and technology to address global issues because of its dedication to sustainability and innovation. With a significant global footprint in more than 90 nations, DuPont remains at the forefront of offering environmentally friendly solutions for a range of sectors.

2. Toray Industries, Inc.

Headquarters: Tokyo, Japan

Toray Industries, Inc., a world leader in sophisticated materials, has its headquarters located in Tokyo, Japan's Nihonbashi Mitsui Tower. The business specialises in a wide variety of goods, such as water treatment membranes, carbon fibre composites, synthetic fibres, and plastics. With its innovative membrane separation technology, Toray is well known for offering wastewater treatment and water purification solutions. Toray is dedicated to sustainability and incorporates environmental factors into both its operations and product development. The business has a large number of subsidiaries across the globe, which increases its influence and global presence in a variety of industries.

3. ASAHI KASEI CORPORATION

Headquarters: Chiyoda-ku, Tokyo

The business works in a number of industries, such as construction materials, electronics, fibres, chemicals, and healthcare. Asahi Kasei is renowned for its inventive membrane separation technologies, which offer wastewater treatment and water purification solutions. The business is a part of the Nikkei 225 and TOPIX 100 stock market indices and is listed on the Tokyo Stock Exchange. Asahi Kasei's efforts to benefit society through its wide range of product offerings are motivated by its dedication to sustainability and technological innovation.

4. BASF SE

Headquarters: Ludwigshafen

The headquarters of the global German chemical corporation BASF SE are located in Ludwigshafen. Chemicals, plastics, performance chemicals, catalysts, coatings, and agricultural technology are just a few of the industries in which BASF, the largest chemical company in the world, works. The business is renowned for its creative solutions across a range of industries, offering goods and services that support developments in sectors like construction, electronics, automotive, and agricultural. BASF's attempts to use research and innovation to address global challenges are motivated by its dedication to sustainability and technical advancement. Serving clients in more than 90 countries and running multiple production facilities across the globe, the company maintains a significant global footprint.

5. SUEZ Group

Headquarters: Paris, France

SUEZ Group, a world leader in water and waste management, has its headquarters in Paris, France's La Défense business district, in the Altiplano skyscraper. With operations in more than 40 nations, the organisation offers vital services to save resources and raise living standards. SUEZ helps clients with their ecological transformation by providing solutions for all stages of asset and service lifecycles. In an effort to lessen its influence on the environment and encourage resource recovery, SUEZ is dedicated to sustainability and concentrates on circular economy projects. The organisation is a reliable partner for both local governments and industrial groups globally because of its experience in water treatment, waste management, and infrastructure development.

Are you ready to discover more about the membrane separation materials market?

The report provides an in-depth analysis of the leading companies operating in the global membrane separation materials market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- DuPont de Nemours, Inc.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Toray Industries, Inc.

- ASAHI KASEI CORPORATION

- BASF SE

- SUEZ Group

- JDA Software

- Epicor Software Corporation

- TECSYS

- Made4net

- Others

Conclusion

The membrane separation materials market is accelerating its The market for membrane separation materials in Japan is expanding significantly due to technical breakthroughs, strict regulations, and industrialisation. The industry is expanding as a result of technological advancements in membrane materials that improve price, longevity, and efficiency. Furthermore, the use of sustainable and eco-friendly processing methods in a variety of industries demonstrates Japan's dedication to cutting-edge water purification technologies.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?