Top 50 Companies in Liquid Milk Aseptic Packaging Market Worldwide 2025: Market Research Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

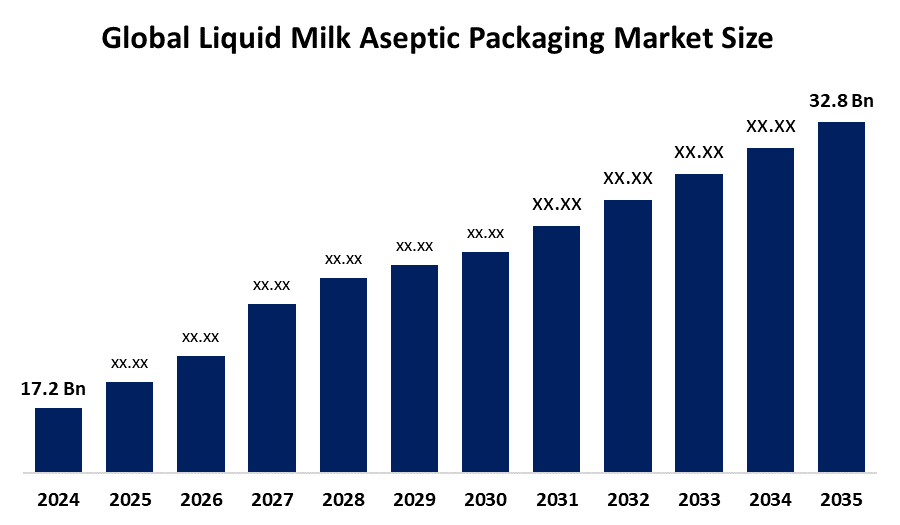

According to a research report published by Spherical Insights & Consulting, The Global Liquid Milk Aseptic Packaging Market Size is projected to Grow from USD 17.2 Billion in 2024 to USD 32.8 Billion by 2035, at a CAGR of 6.04% during the forecast period 2025–2035. The market for liquid milk aseptic packaging is in greater demand as the growing desire for convenient and durable dairy products has been met by improvements in aseptic processing technology, which have increased the shelf life and safety of milk products without the need for refrigeration. The demand for minimally prepared, ready-to-drink milk products is being driven by urbanisation and shifting lifestyles.

Introduction

Liquid milk aseptic packaging is the process of sterilising the milk and its container separately, then filling the container with the sterile milk while maintaining sterility. The market for liquid milk aseptic packaging is expanding significantly on a global scale due to a number of important factors. Aseptic packaging allows for a longer shelf life without refrigeration by sterilising the milk and its container separately before filling. This process stops microbiological growth while maintaining the milk's nutritional value, flavour, and quality. One of the main drivers is the rising demand for dairy products that can be kept on the shelf, especially in cities with inadequate cold chain facilities. The need for convenient, ready-to-drink milk formats among consumers and improvements in packaging technologies further support market growth. Material innovations that improve product sustainability and integrity include multilayer laminates and environmentally friendly packaging options. The use of smart packaging technology, such as QR codes and RFID tags, enhances consumer interaction and traceability. These advancements support the increased focus on environmental sustainability and food safety, which is driving market expansion.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Liquid Milk Aseptic Packaging Market.

Liquid Milk Aseptic Packaging Market Size & Statistics

- The Market Size for Liquid Milk Aseptic Packaging Was Estimated to be worth USD 17.2 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 6.04% between 2025 and 2035.

- The Global Liquid Milk Aseptic Packaging Market Size is anticipated to reach USD 32.8 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Liquid Milk Aseptic Packaging Market

- North America is expected to grow the fastest during the forecast period in the Liquid Milk Aseptic Packaging Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the liquid milk aseptic packaging market. The market for liquid milk aseptic packaging is now growing in North America due to the availability of cutting-edge packaging technology and rising dairy consumption are the main drivers of this expansion. With a focus on food safety and quality, the US and Canada are major suppliers. The growing demand for ready-to-drink, convenient milk products is in line with customers' hectic schedules. The region's adoption of aseptic packaging is further supported by well-established dairy processing businesses and continuous packaging developments.

Asia Pacific is expected to generate the highest demand during the forecast period in the liquid milk aseptic packaging market. The liquid milk aseptic packaging market with the quickest rate of growth throughout the study period is anticipated to be in the Asia Pacific. Rapid urbanisation, growing disposable incomes, and changing food habits in nations like China, India, and Japan are the main drivers of this increase. Aseptically packaged milk products are in high demand due to a growing middle class and increased food safety awareness. The region leads the way in the adoption of aseptic packaging due in part to the growth of contemporary retail channels and the presence of important market competitors.

Top 10 trends in the Liquid Milk Aseptic Packaging Market

- Smart Packaging Integration

- Sustainable Materials

- Lightweight and Cost-Effective Designs

- Automation in Packaging Processes

- Urbanization and On-the-Go Consumption

- Regional Market Dynamics

- E-commerce Growth

- Regulatory Compliance

- Consumer Awareness

- Product Diversification

1. Smart Packaging Integration

In the market for liquid milk aseptic packaging, smart packaging integration improves consumer involvement, product quality, and safety. Time-temperature indicators and freshness sensors are two examples of technologies that track milk quality in real-time and warn consumers of possible spoiling from incorrect storage or temperature changes. Furthermore, NFC tags and QR codes promote consumer trust by providing comprehensive information about the product's origin, nutritional value, and sustainability practices. In addition to improving the customer experience, these innovations also help to increase supply chain efficiency and decrease food waste.

2. Sustainable Materials

The landscape of aseptic milk packaging is becoming more and more defined by the move towards sustainable materials. High-barrier coating innovations like SiOx and EVOH allow for lighter, thinner packaging while extending shelf life. Plant-based laminates and bio-based polymers like PLA are lowering carbon footprints and dependency on plastics made from fossil fuels, while mono-material designs increase recyclability by streamlining separation procedures. Leading companies have made significant contributions to sustainability goals by introducing aseptic boxes made of renewable materials. The sector is positioned for greener, more circular operations due to these material breakthroughs, which also promote prolonged product freshness and comply with consumer and regulatory demands for eco-conscious packaging.

3. Lightweight and Cost-Effective Designs

The distribution and storage of liquid milk are being revolutionised by aseptic packaging solutions that are both economical and lightweight. Compared to conventional glass or metal containers, aseptic cartons and pouches are substantially lighter, which lowers transportation emissions and simplifies logistics. Particularly, pouches are incredibly space-efficient, adaptable, and frequently less expensive, making them the perfect choice for budget-conscious consumers. In addition to using less material, innovations like sleek and single-serve sizes accommodate busy lives, improving shelf visibility and consumer convenience. All things considered, packaging that is lighter and more efficient offers benefits to the economy and the environment while preserving functionality and safety.

4. Automation in Packaging Processes

Automation is improving speed, accuracy, and hygiene in aseptic milk packing. In sterile settings, modern aseptic filling systems streamline procedures, including capping, sealing, and filling to reduce contamination and human error while increasing operational effectiveness and product safety. Modern equipment combines robotics, inline quality control, and real-time temperature and pressure monitoring to guarantee constant standards and prompt remedial action. IoT sensors and AI-powered analytics are two examples of Industry 4.0 technologies that are further streamlining manufacturing processes, facilitating predictive maintenance, decreasing downtime, and increasing throughput.

5. Urbanization and On-the-Go Consumption

Convenient, ready-to-drink milk products are in high demand as a result of the rapid urbanisation that has changed consumption habits. Portable, single-serve aseptic formats, such as 100–250 ml cartons and pouches, are preferred by busy urban lives because they are easy to transport, require no preparation, and don't need to be refrigerated. Convenience stores, schools, offices, and transport hubs are increasingly carrying these little options to satisfy customers looking for convenient consumption. The market for dairy aseptic packaging is actually dominated by the 100–250 ml sector, which is bolstered by widespread use in Chinese and European cities. Urban demographics and changing lifestyles are driving innovation in the direction of stylish, portable dairy packaging.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the liquid milk aseptic packaging market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 19 Companies Leading the Liquid Milk Aseptic Packaging Market

- Stora Enso Oyj

- Sealed Air Corporation

- Ecolean AB

- Mondi Group

- Tetra Pak International S.A.

- Nippon Paper Industries Co., Ltd.

- SIG Combibloc Group AG

- DuPont de Nemours, Inc.

- Weyerhaeuser Company

- Scholle IPN

- Elopak AS

- Amcor Limited

- Smurfit Kappa Group

- Greatview Aseptic Packaging Co., Ltd.

- Uflex Ltd.

- BillerudKorsnas AB

- Tetra Pak

- Evergreen Packaging LLC

- IPI Srl

- Others

1. Stora Enso Oyj

Headquarters: Helsinki, Finland

Stora Enso Oyj is a prominent provider of renewable materials, creating and supplying wood- and biomass-based solutions for a range of sectors. The company, which specialises in paper, biomaterials, wooden construction, and packaging materials, helps customers create low-carbon, more sustainable supply routes. Its wide-ranging global presence includes Europe, Asia, Africa, and the Americas, catering to industries like retail, medicines, cosmetics, food and beverage, hygiene, industrial packaging, and construction. Stora Enso, which has its headquarters in Helsinki, Finland, and a sizable presence in Stockholm, Sweden, seeks to comply with eco-conscious and circular economy concepts by substituting renewable resources for fossil fuel-based ones.

2. Sealed Air Corporation

Headquarters: North Carolina, United States

Sealed Air Corporation is a leading provider of packaging solutions worldwide, renowned for improving supply chain effectiveness, food safety, and product protection. Famous brands, including Bubble Wrap (protective cushioning), CRYOVAC (food packaging), Autobag, Liquibox, and SEE (protective systems), fall under its purview. These products cater to a variety of markets, including e-commerce, industrial sourcing, food and healthcare, and more. The business offers cutting-edge paper, foam, and film-based packaging materials in addition to integrated automation systems that simplify packing and cut waste.

3. ECOLEAN AB

Headquarters: Helsingborg, Sweden

The dairy and liquid food industries are served by Ecolean AB, a global system provider that provides packaging solutions, filling technology, downstream equipment, and services for both chilled and ambient products such as milk, yoghurt, cream, plant-based beverages, and still drinks. The organisation aggressively reduces food waste and improves food safety while promoting a lightweight packaging philosophy and producing containers that use the fewest resources possible throughout their lifecycle, from sourcing raw materials to production, distribution, and disposal. Consumer convenience and environmental benefits are provided by Ecolean's unique lightweight packages, which are easy to grasp, open, pour from, microwave-safe, and lie flat when empty. Sweden's Helsingborg serves as the company's headquarters.

4. Mondi Group

Headquarters: Weybridge, England

Corrugated Packaging, Flexible Packaging, and Uncoated Fine Paper are the three primary business segments of Mondi Group, a world pioneer in environmentally friendly packaging and paper solutions. Its corrugated segment is the leading manufacturer of virgin containerboard in Europe, and its flexible packaging section provides lightweight packaging solutions, kraft paper, and hybrid materials for the consumer and industrial markets. Printing and office supply markets are served by the uncoated fine paper segment. Mondi's MAP2030 sustainability framework, which aims to make all of its goods recyclable, compostable, or reusable by 2023, is a key component of its strategy. The company's main office is situated in Weybridge, England, in the United Kingdom.

5. Tetra Pak International S.A.

Headquarters: Vaud, Switzerland

A leader in food processing, packaging, and distribution solutions worldwide is Tetra Pak International S.A. For goods including dairy, liquids, cheese, ice cream, and prepared foods, the company provides end-to-end systems: aseptic cartons, filling machines, and downstream packaging equipment. Its comprehensive solutions, which include packaging, automation, processing equipment, design, installation, and after-sales services, are all intended to maximise resource utilisation while maintaining food safety and quality. With its main office in Pully, Vaud, Switzerland, and a strong connection to its Swedish heritage, Tetra Pak serves a variety of markets worldwide with strong engineering, innovative sustainable packaging, and a dedication to environmental performance and food safety.

Are you ready to discover more about the liquid milk aseptic packaging market?

The report provides an in-depth analysis of the leading companies operating in the global liquid milk aseptic packaging market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Stora Enso Oyj

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Sealed Air Corporation

- ECOLEAN AB

- Mondi Group

- Tetra Pak International S.A.

- Nippon Paper Industries Co., Ltd.

- SIG Combibloc Group AG

- DuPont de Nemours, Inc.

- Weyerhaeuser Company

- Scholle IPN

- Elopak AS

- Amcor Limited

- Smurfit Kappa Group

- Greatview Aseptic Packaging Co., Ltd.

- Uflex Ltd.

- BillerudKorsnas AB

- Tetra Pak

- Evergreen Packaging LLC

- IPI Srl

- Others

Conclusion

The liquid milk aseptic packaging market is accelerating due to the growing customer appetite for goods with longer shelf lives is one of the main factors. By removing dangerous bacteria during the packaging process, aseptic packaging methods maintain milk and dairy products without the need for refrigeration, guaranteeing their freshness and safety. This is especially advantageous in areas with inadequate cold chain infrastructure. Major industry participants are also spending money on R&D to improve their product offerings, with an emphasis on innovations in sustainable solutions, technology, and packaging materials. The competitive landscape is also being influenced by strategic activities like market expansion, mergers, and acquisitions, which help businesses adapt to changing customer needs and legal constraints.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?