Top 50 Companies in Industry 4.0 Market : Market Research Report (2024–2035)

RELEASE DATE: Jul 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

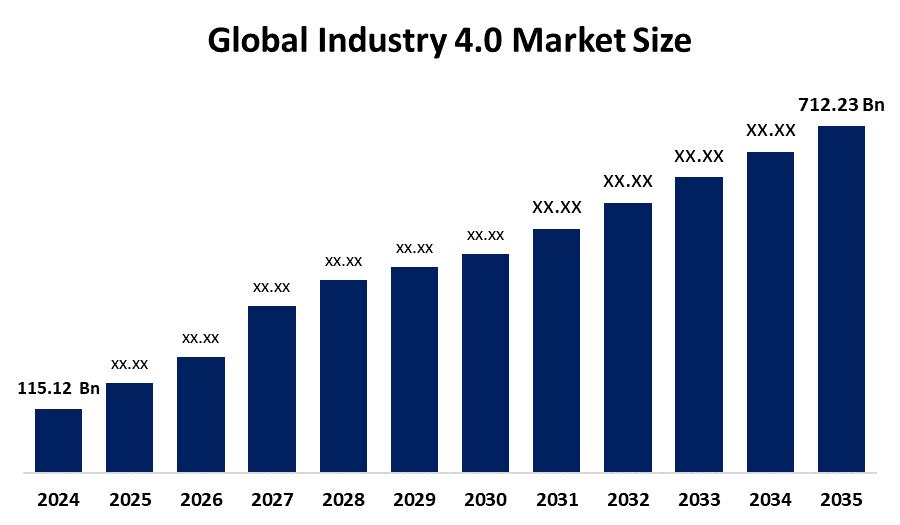

According to a research report published by Spherical Insights & Consulting, The Global Industry 4.0 Market Size is projected To grow from USD 115.12 Billion in 2024 to USD 698.56 Billion by 2035, at a CAGR of 18.02% during the forecast period 2025–2035. Industries are transitioning from antiquated production techniques to digital ones, utilizing robotics and automation technology such as AIoT (Artificial Intelligence of Things). Over 1000 firms that have adopted AIoT have seen an increase in production, according to World Economic Forum research. This has enabled large-scale product customization and ensured profitable operations.

Introduction

A disruptive era for organizations is being ushered in by Industry 4.0, which is significantly changing the way that products are developed, manufactured, and distributed. Modern technologies like artificial intelligence, machine learning, cloud computing, analytics, and the Internet of Things (IoT) are being easily incorporated into manufacturing facilities and organizational structures by manufacturers. Robots, embedded software, and advanced sensors are all installed in smart factories to gather and analyze data and make better decisions. By combining operational data from business systems such as ERP, supply chain, and customer service with production data, previous data silos are broken down and new insights and visibility are provided. The industry is moving toward greater automation, predictive maintenance, self-optimization of operations, and, above all, unprecedented efficiency and customer response due to these digital technologies. Productivity and quality are raised when smart factories employ contemporary IoT devices. By replacing human inspection techniques with AI-driven visual insights, production errors are decreased, saving money and time. Industry 4.0's concepts and technologies are broadly applicable to a wide range of industries, including mining, oil and gas, discrete and process manufacturing, and many other industrial sectors.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Industry 4.0 Market.

Industry 4.0 Market Size & Statistics

- The Market for industry 4.0 was estimated to be worth USD 115.12 Billion in 2024.

- The Market is going to expand at a CAGR of 18.02% between 2025 and 2035.

- The Global Industry 4.0 Market Size is anticipated to reach USD 712.23 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the industry 4.0 Market

- Asia-Pacific is expected to Grow the fastest during the forecast period in the industry 4.0 Market.

Regional growth and demand

Asia-Pacific is expected to grow the fastest during the forecast period in the industry 4.0 market. The Asia-Pacific region headed by China has dominated the world's industry. Therefore, in order to remain competitive with its Western rivals, countries such as China, Japan, and South Korea are investing heavily in the fourth industrial revolution. This is where Industry 4.0 is becoming noticeable. China's "Made in China" initiative, which is based on Germany's Industry 4.0 concept but is more implemented, includes large investments, mostly in Chinese sectors, from a number of state-directed entities.

North America is expected to generate the highest demand during the forecast period in the industry 4.0 market. The advent of Industry 4.0 can be ascribed to a number of important factors, such as the rapid pace of technological development, the substantial financial support of regional governments, and coordinated efforts to implement real-time quality control and improved visibility across the manufacturing sector. The presence of a strong industrial sector and the use of cutting-edge technological advancements are the main factors propelling Industry 4.0's progress in North America.

Top 10 trends in Industry 4.0 Market

- Artificial intelligence and machine learning

- Human augmentation and extended reality

- Edge, fog, and cloud computing

- Advanced robotics and cobots

- Digital twins and simulation

- Industrial Internet of Things (IIoT)

- Cybersecurity and zero-trust architecture

- Additive manufacturing (3D printing)

- Hyperautomation and smart workflows

- Sustainable and green manufacturing

- Artificial intelligence and machine learning

AI is the brain behind Industry 4.0. It powers predictive maintenance, quality control, demand forecasting, and autonomous decision-making. From smart factories to supply chains, AI algorithms optimize operations, reduce waste, and enhance productivity. Machine learning models continuously improve by analyzing real-time data, making industrial systems more adaptive and intelligent.

- Human augmentation and extended reality

Technologies like exoskeletons, AR, VR, and mixed reality are enhancing worker capabilities. They reduce physical strain, improve safety, and enable immersive training. In manufacturing, AR overlays real-time data on equipment, while VR simulates complex procedures for hands-on learning. These tools bridge the gap between human intuition and machine precision.

- Edge, fog, and cloud computing

Data is the lifeblood of Industry 4.0, and these computing layers ensure it flows efficiently. Edge computing processes data close to the source for real-time decisions. Fog computing adds a middle layer for localized analysis, while cloud computing handles large-scale storage and deep analytics. Together, they enable smart, connected ecosystems.

- Advanced robotics and cobots

Robots are no longer isolated machines they’re collaborative teammates. Cobots work safely alongside humans, handling repetitive or hazardous tasks. Swarm robotics and autonomous mobile robots are transforming logistics and assembly lines. These systems are becoming more flexible, intelligent, and responsive to dynamic environments.

- Digital twins and simulation

A digital twin is a virtual replica of a physical asset, system, or process. It allows companies to simulate scenarios, monitor performance, and predict failures before they happen. In Industry 4.0, digital twins are used for everything from product design to factory optimization, enabling data-driven decisions and continuous improvement.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the industry 4.0 market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the Industry 4.0 Market

- Siemens AG

- Bosch

- Volkswagen Group

- Toyota Motor Corporation

- General Electric (GE)

- ABB Ltd.

- Intel Corporation

- Cisco Systems Inc.

- Schneider Electric SE

- IBM Corporation

- Honeywell International Inc.

- Rockwell Automation, Inc.

- Mitsubishi Electric Corporation

- Emerson Electric Co.

- Fanuc Corporation

- DENSO Corporation

- SAP SE

- Stratasys Ltd.

- Swisslog Holding AG

- Techman Robot Inc.

- Cognex Corporation

- Hewlett-Packard Enterprise

- Nvidia Corporation

- Toshiba Corporation

- Infinite Uptim

- Siemens AG

Headquarters - Munich, Germany

Siemens is a trailblazer in Industry 4.0, integrating automation, AI, and digital twin technologies across industrial ecosystems. Its Electronic Works Amberg plant exemplifies smart manufacturing, with over 75% of production automated using Siemens’ own Simatic PLCs. The company’s Digital Industries division offers solutions for edge computing, IIoT, and simulation, enabling real-time optimization. Siemens also leads in cybersecurity and sustainability, making it a benchmark for Industry 4.0 excellence. With a global footprint and deep R&D investment, Siemens empowers industries to digitize operations and boost productivity.

- Bosch

Headquarters – Gerlingen, Germany

Bosch is redefining Industry 4.0 through its dual role as a manufacturer and solution provider. Its Rexroth division delivers adaptive production systems, connected value chains, and intelligent operator assistance. Bosch’s own plants serve as testbeds for innovations before market rollout, ensuring practical relevance. The company emphasizes human-machine collaboration, offering vocational training to upskill workers for digital roles. Bosch’s commitment to flexible, customer-centric manufacturing makes it a key player in Industry 4.0 transformation.

- Volkswagen Group

Headquarters – Wolfsburg, Germany

Volkswagen has invested over €4 billion in digitalization, positioning itself as a leader in Industry 4.0 within automotive manufacturing. Its smart factories leverage robotics, real-time monitoring, and AI to produce customized vehicles without disrupting production lines. Human-robot interaction is central to its strategy, blending precision with human expertise. Volkswagen’s “Digital Transformation Road” reflects its ambition to create agile, data-driven production environments. The company’s scalable approach to automation sets a precedent for Industry 4.0 adoption in large-scale manufacturing.

- Toyota Motor Corporation

Headquarters - Toyota City, Japan

Toyota’s Industry 4.0 philosophy centers on enhancing, not replacing, human labor. At its Kentucky plant, automation complements skilled workers, maintaining high quality and efficiency. Toyota integrates smart robotics, IIoT, and predictive analytics while preserving its human-centric ethos. The company invests heavily in employee training to foster innovation and adaptability. Toyota’s balanced approach to automation and human involvement makes it a unique contributor to Industry 4.0, especially in promoting sustainable and inclusive manufacturing.

- General Electric (GE)

Headquarters -Boston, Massachusetts, USA

GE is a pioneer in Industry 4.0, transforming traditional sectors with software-defined machines and connected solutions. Its Predix platform enables cloud-based industrial analytics, while Digital Windfarm technology boosts energy output using real-time data. GE’s focus spans energy, healthcare, and transportation, applying Industry 4.0 to optimize operations and reduce downtime. Despite internal restructuring challenges, GE remains a key innovator, demonstrating how legacy firms can evolve through digital transformation.

Are you ready to discover more about the industry 4.0 market?

The report provides an in-depth analysis of the leading companies operating in the global industry 4.0 market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Siemens AG

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Bosch

- Volkswagen Group

- Toyota Motor Corporation

- General Electric (GE)

- ABB Ltd.

- Intel Corporation

- Cisco Systems Inc.

- Schneider Electric SE

- Others.

Conclusion

The global Industry 4.0 market is rapidly evolving, driven by smart technologies like AI, robotics, and cloud computing that are transforming manufacturing and industrial operations. Regions such as North America are leading the charge with strong demand, while Asia-Pacific is emerging as a hub of accelerated growth due to strategic investments and government-backed initiatives. As digital ecosystems become more integrated, companies are embracing intelligent automation, sustainable practices, and real-time insights to stay ahead.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?