Top 50 Companies in Global High Temperature Tube Furnace Market (2025–2035): Competitive Analysis and Forecast

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

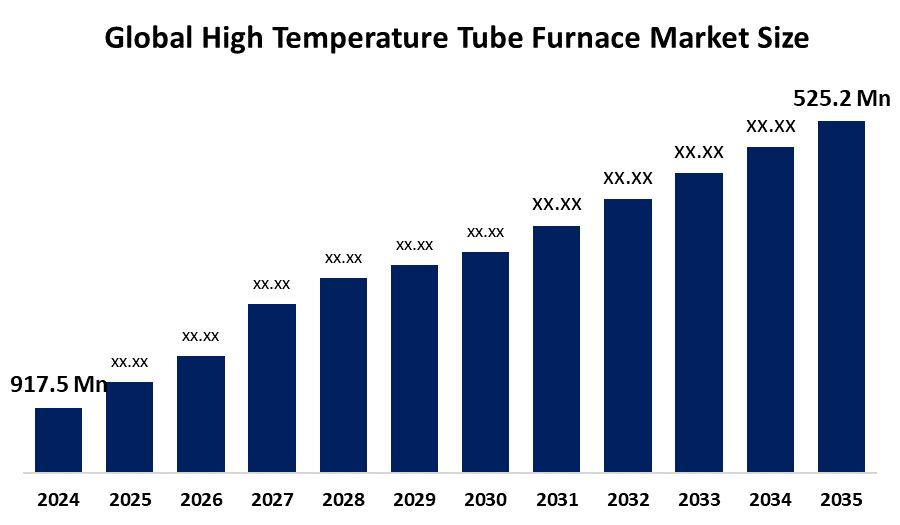

According to a research report published by Spherical Insights & Consulting, The Global High Temperature Tube Furnace Market Size is projected To Grow from USD 525.3 Million in 2024 to USD 917.5 Million by 2035, at a CAGR of 5.2% during the forecast period 2025–2035. The market for high temperature tube furnaces increases due to a surge in demand for sophisticated material research, industrial heat treatment, sustainable technologies, growing electronics and aerospace industries, and growing investments in R&D and manufacturing.

Introduction

The high temperature tube furnace market refers to equipment that can heat materials to very high temperatures in a controlled atmosphere, mainly applied to research, material testing, and industrial treatments such as sintering, annealing, and heat treatment. These furnaces have applications in industries such as metallurgy, ceramics, electronics, and aerospace, where temperature control with accuracy and consistent heating are important. A Controlled Atmosphere Furnace Market Size provides optimal conditions for various processes by delivering controlled temperature and atmosphere required for specific tasks. Market development is fueled by growing R&D operations, increasing demand for sophisticated materials, and growing demand for optimal thermal processing solutions. Principal market strengths are technological improvements, including improved temperature uniformity, energy efficiency, and automation capabilities, which improve performance and lower operating costs. The opportunities are in developing economies where industrialization and scientific studies are increasing at a fast pace, with the growing adoption in the semiconductor and battery production sectors. Governments across the world promote the market through financial support for sophisticated research infrastructure, environmental policies promoting sustainable technologies, and programs to improve manufacturing capacities.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the High Temperature Tube Furnace Market.

High Temperature Tube Furnace Market Size & Statistics

- The Market Size for High Temperature Tube Furnace Was Estimated to be worth USD 525.3 Million in 2024.

- The Market is Going to Expand at a CAGR of 5.2% between 2025 and 2035.

- The Global High Temperature Tube Furnace Market Size is anticipated to reach USD 917.5 Million by 2035.

- Asia Pacific is expected to generate the largest demand during the forecast period in the High Temperature Tube Furnace Market

- North America is expected to grow the fastest during the forecast period in the High Temperature Tube Furnace Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the high temperature tube furnace market. North America is the most rapidly growing high temperature tube furnace market due to its focus on advanced R&D, availability of major manufacturers, growth in the aerospace and semiconductor industries, and growth in the adoption of sustainable solutions supported by government policies and heavy investments in innovation and manufacturing infrastructure.

Asia Pacific is expected to generate the largest demand during the forecast period in the high temperature tube furnace market. Asia Pacific is the dominating market for high temperature tube furnaces, attributed to rapid growing industrialization, a vibrant electronics and automotive sector, and growing research and development activities. China, India, and Japan are heavily investing in sophisticated manufacturing and material science, and this is fueling demand for efficient and accurate thermal processing equipment in different industry segments such as aerospace, semiconductors, and energy storage.

Top 10 trends in the High Temperature Tube Furnace Market

- Advancements in energy-efficient furnaces

- Rising demand from semiconductor industry

- Automation and smart controls

- Growth in aerospace and automotive sectors

- Adoption of advanced materials

- Customization and modular designs

- Focus on compact and portable furnaces

- Sustainability and green manufacturing

- Expansion in emerging economies

- Enhanced safety features

1. Advancements in energy-efficient furnaces

Technologies in high temperature tube furnaces center on precision control using AI, advanced insulation materials such as silicon carbide and zirconium oxide, and innovative heat recovery systems to reduce energy loss and emissions. These emerging trends improve product quality and sustainability through improved thermal efficiency and increased furnace life.

2. Rising demand from semiconductor industry

Growth in semiconductor demand from AI, 5G, and EVs drives the requirement for high temperature tube furnaces of advanced quality for precision manufacturing. The furnaces, using methods such as vacuum heat treatment and novel materials, provide the high quality and performance of devices such as AI chips and power semiconductors, leading the furnace market to grow.

3. Automation and smart controls

Automation and intelligent control tendencies, such as AI, IoT, and effective sensors, allow high temperature tube furnaces to provide accurate, real-time temperature control, sustainable optimization, and remote control. This results in better product quality, lower operating costs, improved safety, predictive maintenance, and low downtime for a more efficient and sustainable process.

4. Growth in aerospace and automotive sectors

Expansion in aerospace and automotive industries demands High Temperature Tube Furnaces (HTFs) for heat treating advanced materials such as alloys to realize desired strength and heat resistance for stringent components to perform under extreme conditions. HTFs further enable green manufacturing by providing sustainable, precision processes critical for these advanced industries.

5. Adoption of advanced materials

Higher temperature tube furnaces are improved through advanced materials by providing higher thermal strength and toughness, allowing higher temperatures of operation with greater integrity and greater service life. The trends are in the application of refractory ceramics and composites as linings that permit higher process temperatures, greater energy efficiency, and less maintenance in processes such as synthesis of advanced materials.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the high temperature tube furnace market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 20 Companies Leading the High Temperature Tube Furnace Market

- Thermo Fisher Scientific Inc.

- Nabertherm GmbH

- Carbolite Gero Limited

- Sentro Tech Corporation

- MTI Corporation

- CM Furnaces, Inc.

- Thermcraft

- Hobersal

- Abbott Furnace Company

- Surface Combustion Inc.

- The Grieve Corporation

- Dowa Thermotech Co., Ltd.

- ULVAC Inc.

- Andritz AG

- Harrier Enterprises

- Vecstar Ltd.

- Lenton Furnaces & Ovens

- Keith Company

- Yamato Scientific Co., Ltd.

- Materials Research Furnaces, LLC

1. Thermo Fisher Scientific Inc.

Headquarters: Waltham, Massachusetts, USA

Thermo Fisher Scientific Inc. is a worldwide leader in laboratory equipment and scientific instrumentation. In the high temperature tube furnace industry, they provide innovative, customizable tube furnace solutions under the Lindberg and MPH brand. The furnaces have broad application in research, materials science, and industry for accurate heat treatment, synthesis of material, and testing. Thermo Fisher tube furnaces are recognized through reliability, temperature stability, and compatibility with modern controls, which facilitate innovation in laboratories globally.

2. Nabertherm GmbH

Headquarters: Lilienthal, Germany

Nabertherm GmbH, a prominent manufacturer of industrial and laboratory furnaces, such as high temperature tube furnaces. The company's area of expertise lies in developing strong, conserve tube furnaces used in heat treatment, sintering, and material testing in a wide range of industries such as ceramics, metallurgy, and electronics. Nabertherm products are recognized for their accurate control of temperature, longevity, and flexibility, serving research centers and industrial clients globally, facilitating developments in materials processing and thermal applications.

3. Carbolite Gero Limited

Headquarters: Hope Valley, Derbyshire, United Kingdom

Carbolite Gero Limited specialize in the production of high temperature ovens and furnaces, mainly concentrating on tube furnaces applied in industrial and research situations. Their furnaces are recognized for accuracy, dependability, and sophisticated temperature control, serving industries such as materials science, metallurgy, and electronics. Carbolite Gero is a major supplier in the high temperature tube furnace industry, offering customized solutions that enable essential processes involving continuous and uniform heating at high temperatures.

4. Sentro Tech Corporation

Headquarters: Strongsville, Ohio, United States

Sentro Tech Corporation specialize in designing and producing high temperature tube furnaces for industrial and scientific applications. They are famous for furnaces that offer accurate temperature control, long durability, and a high degree of energy efficiency, catering to industries including materials science, ceramics, and semiconductor processing. Sentro Tech specializes in providing tailor-made solutions to meet special thermal processing requirements, and for this reason, they are a well-known name in high temperature tube furnaces for applications demanding consistent and trusted heating performance.

5. MTI Corporation

Headquarters: Richmond, California, USA

MTI Corporation is a renowned provider of high temperature tube furnaces and associated laboratory equipment for the research and industrial markets. MTI Corporation distributes tube furnaces of all sizes with precision, flexibility, and sophisticated temperature control, which are ideal for use in materials science, nanotechnology, and electronics applications. Their equipment enables processes needing dependable, uniform heating under high temperatures, making MTI a prominent position in the high temperature tube furnace business.

Are you ready to discover more about the high temperature tube furnace market?

The report provides an in-depth analysis of the leading companies operating in the global high temperature tube furnace market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Thermo Fisher Scientific Inc.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Nabertherm GmbH

- Carbolite Gero Limited

- Sentro Tech Corporation

- MTI Corporation

- CM Furnaces, Inc.

- Thermcraft

- Hobersal

- Abbott Furnace Company

- Others.

Conclusion

The high temperature tube furnace market provides to industries such as metallurgy, electronics, and aerospace, providing accurate, efficient heating for research and manufacturing applications. Industry leaders, Thermo Fisher, Nabertherm, Carbolite Gero, Sentro Tech, and MTI Corporation, offer sophisticated, customizable furnaces with intelligent controls and lasting materials. Semiconductor demand, automation, and aerospace and automotive industry growth are fueling market growth, aided by government support and advancements in energy efficiency, temperature uniformity, and sustainable manufacturing technology.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?