Top 50 Companies in Friction Materials Market: Key Insights and Innovations

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

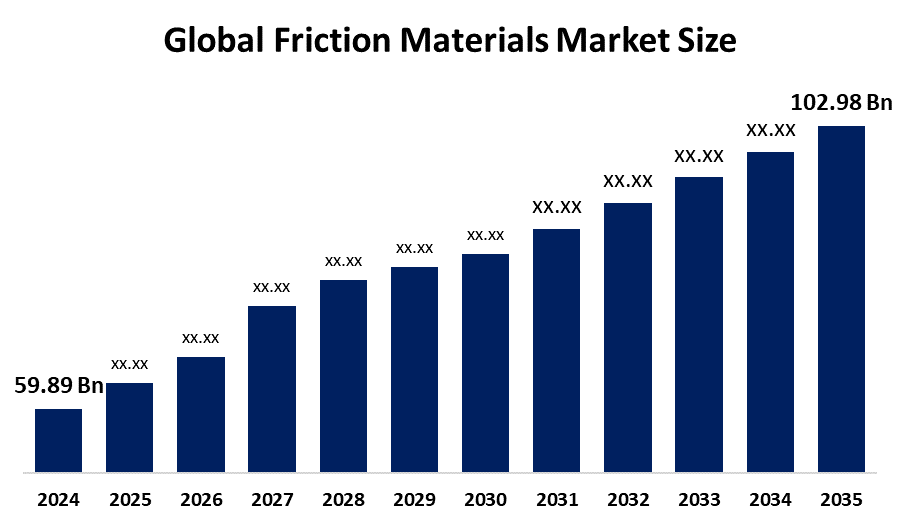

According to a research report published by Spherical Insights & Consulting, The Global Friction Materials Market Size is projected To Grow from USD 59.89 Million in 2024 to USD 102.98 Million by 2035, at a CAGR of 5.05% during the forecast period 2025–2035. People have been moving to metropolitan areas due to the growing urbanization of the world, particularly in emerging nations, where the transportation infrastructure frequently struggles to keep up with the growing population.

Introduction

Materials that create friction between two solid surfaces to regulate or halt forward or backward motion are known as friction materials. Organic fibers like rubber, resin, and aramid; sintered metals like copper, steel, and brass; and ceramics are among the materials used to make friction materials. Products created with friction materials include brake shoes and pads, clutches, friction discs, friction linings, friction pads, friction plates, brake linings for railroads and airplanes, and industrial clutches and brakes. For safe, controlled power transmission or wear-free braking, friction materials are essential. These materials provide the necessary traction for cars to slow down.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Friction Materials Market.

Friction Materials Market Size & Statistics

- The Market Size for Friction Materials Was Estimated to be worth USD 59.89 Million in 2024.

- The Market Size is Going to Expand at a CAGR of 5.05% between 2025 and 2035.

- The Global Friction Materials Market Size is anticipated to reach USD 102.98 Million by 2035.

- North America is expected to generate the highest demand during the forecast period in the Friction Materials Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Friction Materials Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the friction materials market. Rapid industrialization, urbanization, and expanding automotive manufacturing are key drivers in Asia Pacific. The region’s large population and rising middle class boost demand for passenger vehicles and consumer electronics, increasing the need for advanced friction materials. Additionally, stringent government regulations on vehicle safety and emissions promote the adoption of eco-friendly, high-performance friction materials. Growth in electric vehicle production further accelerates market expansion in this region.

North America is expected to generate the highest demand during the forecast period in the friction materials market. In North America, rising safety standards and stringent environmental regulations drive demand for sustainable, non-asbestos friction materials. The presence of major automotive OEMs and growing investment in electric and hybrid vehicles spur innovation and adoption of advanced friction solutions. Additionally, expansion in aerospace, industrial machinery, and railway sectors supports market growth. Emphasis on reducing vehicle emissions and improving fuel efficiency also propels demand for lightweight, high-performance friction materials.

Top 5 trends in the Friction Materials Market

- Growing Demand for Eco-Friendly and Non-Asbestos Friction Materials

- Increased Adoption of Advanced Composite Materials

- Expansion in Automotive and Electric Vehicle (EV) Applications

- Technological Innovations in Thermal and Wear Resistance

- Rising Use in Industrial and Railway Sectors

Trend Explanations

1. Growing Demand for Eco-Friendly and Non-Asbestos Friction Materials

Environmental regulations and health concerns are driving the shift from traditional asbestos-based materials to eco-friendly alternatives. Manufacturers are investing in safe, non-toxic friction materials that reduce emissions and comply with stringent safety standards, boosting market growth.

2. Increased Adoption of Advanced Composite Materials

Composite friction materials combining ceramics, metals, and fibers are increasingly used to improve braking performance and durability. These advanced materials offer better thermal stability and wear resistance, leading to enhanced safety and longer product life in automotive and industrial applications.

3. Expansion in Automotive and Electric Vehicle (EV) Applications

The rapid growth of the automotive sector, especially electric vehicles, is propelling demand for friction materials optimized for regenerative braking and lightweight design. EV-specific friction solutions cater to different wear profiles and contribute to vehicle efficiency and safety.

4. Technological Innovations in Thermal and Wear Resistance

Manufacturers are developing friction materials with superior thermal management and wear resistance to cope with high-speed and heavy-load applications. These innovations improve braking reliability and maintenance intervals, critical for both consumer and commercial vehicles.

5. Rising Use in Industrial and Railway Sectors

Friction materials are increasingly adopted in heavy machinery and railway braking systems due to their ability to withstand harsh conditions. Growth in these sectors fuels demand for customized, high-performance friction solutions that enhance safety and operational efficiency.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the friction materials market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 25 Companies Leading the Friction Materials Market

- Hitachi Chemical Company, Ltd.

- Federal-Mogul, Inc. (A Tenneco Company)

- BASF SE

- BorgWarner Inc.

- Nisshinbo Holdings Inc.

- Akebono Brake Industry Co., Ltd.

- TMD Friction Holdings GmbH

- Sumitomo Riko Company Limited

- Continental AG

- Honeywell International Inc.

- Miba AG

- SKF Group

- NTN Corporation

- China Brake System Co., Ltd.

- Meritor, Inc.

- Federal-Mogul Powertrain

- Cifarelli Friction Group

- Federal-Mogul Motorparts

- Brembo S.p.A

- Ashimori Industry Co., Ltd.

- Minth Group Limited

- Winhere Automotive Group Co., Ltd.

- Showa Corporation

- ZF Friedrichshafen AG

- TE Connectivity Ltd.

1. Hitachi Chemical Company, Ltd.

Headquarters: Tokyo, Japan

Hitachi Chemical Company is a major player in the friction materials market, offering advanced braking and friction solutions for automotive and industrial applications. The company specializes in producing high-performance friction materials that deliver superior thermal resistance, durability, and noise reduction. With a focus on innovation, Hitachi Chemical integrates cutting-edge composite materials and sustainable manufacturing practices to meet stringent regulatory demands. Their products are widely used in passenger vehicles, commercial trucks, and industrial machinery worldwide. Hitachi Chemical leverages decades of expertise in materials science, emphasizing eco-friendly and safe friction compounds that support the growing demand for electric vehicle braking systems, positioning the company as a leader in the evolving friction materials market.

2. Federal-Mogul, Inc. (A Tenneco Company)

Headquarters: Southfield, Michigan, USA

Federal-Mogul is a global leader in the friction materials market, producing brakes, clutches, and other friction components for automotive, commercial, and industrial sectors. Known for innovation, Federal-Mogul develops advanced composite friction materials that improve brake performance, reduce wear, and enhance thermal stability. The company continuously invests in R&D to produce eco-friendly, non-asbestos friction solutions responding to evolving environmental regulations. Serving both aftermarket and OEM customers worldwide, Federal-Mogul supports the growing electric vehicle (EV) market by developing specialized braking solutions optimized for regenerative braking systems. Federal-Mogul’s robust product portfolio and global reach make it a key entity in the friction materials industry.

3. BASF SE

Headquarters: Ludwigshafen, Germany

BASF SE is a global chemical industry leader engaged in developing high-quality friction materials that cater to automotive and industrial needs. Their advanced composites and polymer solutions enhance braking efficiency, wear resistance, and thermal performance. BASF prioritizes sustainability by innovating non-asbestos and eco-friendly friction formulations that reduce environmental and health impacts. The company serves leading automotive OEMs and aftermarket suppliers with customized friction materials adapted for electric vehicles and traditional combustion engine vehicles. With strong R&D capabilities, BASF drives technological advancements that improve safety and performance, establishing its position as a frontrunner in the rapidly evolving friction materials market.

4. BorgWarner Inc.

Headquarters: Auburn Hills, Michigan, USA

BorgWarner is a prominent supplier of friction materials focusing on automotive and commercial vehicle braking solutions. The company develops cutting-edge friction compositions designed for enhanced performance, noise reduction, and durability. BorgWarner invests significantly in sustainable, non-asbestos friction technologies aligned with global environmental standards. Their product range, including brake pads and clutch materials, supports the needs of electric and hybrid vehicles, emphasizing lightweight designs and regenerative braking compatibility. Serving major OEMs worldwide, BorgWarner's innovation-driven approach and global manufacturing capabilities ensure its strong standing in the friction materials market, addressing industry shifts toward cleaner, safer, and more efficient transportation solutions.

5. Nisshinbo Holdings Inc.

Headquarters: Tokyo, Japan

Nisshinbo Holdings is a leading manufacturer specializing in friction materials used in automotive braking and industrial applications. The company excels in producing high-performance brake pads, discs, and friction compounds with a strong focus on thermal stability, wear resistance, and low noise characteristics. Nisshinbo invests in research to develop environmentally friendly, non-asbestos materials, meeting stringent regulatory requirements and the demands of the growing electric vehicle market. Their global presence and continuous innovation position Nisshinbo Holdings as a critical player in the friction materials market, supplying OEMs and aftermarket customers with reliable and sustainable friction solutions.

Are you ready to discover more about the friction materials market?

The report provides an in-depth analysis of the leading companies operating in the global friction materials market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Hitachi Chemical Company, Ltd.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Federal-Mogul, Inc. (A Tenneco Company)

- BASF SE

- BorgWarner Inc.

- Nisshinbo Holdings Inc.

- Akebono Brake Industry Co., Ltd.

- TMD Friction Holdings GmbH

- Sumitomo Riko Company Limited

- Continental AG

- Others.

Conclusion

The Friction Materials Market Size is poised for steady growth driven by increasing demand for eco-friendly, non-asbestos materials and technological advancements in composite formulations. Expansion in automotive, especially electric vehicle sectors, coupled with rising safety regulations, fuels the adoption of high-performance friction solutions. Innovations enhancing thermal stability, wear resistance, and noise reduction further strengthen market prospects. Growth in industrial and railway applications also contributes significantly. Overall, the market outlook is positive, with sustainability and advanced materials driving future developments, offering ample opportunities for manufacturers to innovate and expand globally.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?