Top 45 Global Companies in Broaching Machines Market 2025: Strategic Overview and Future Trends (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

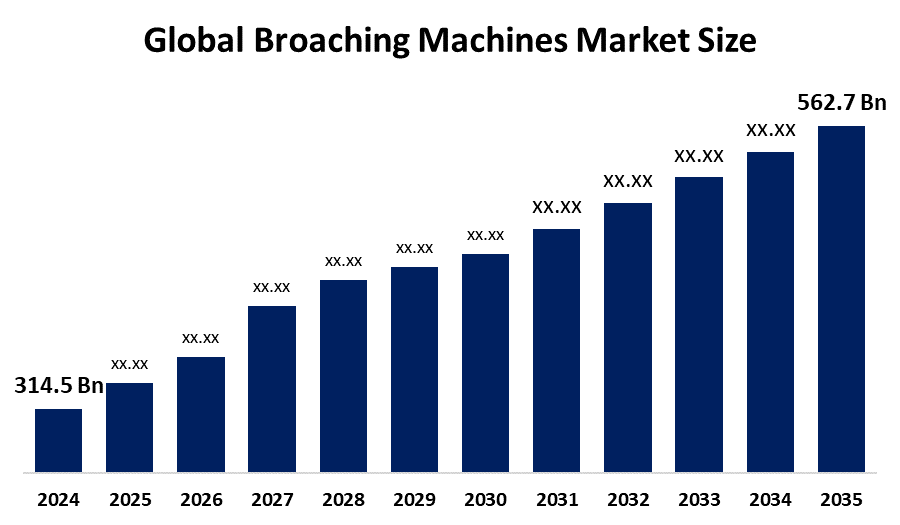

According to a research report published by Spherical Insights & Consulting, The Global Broaching Machines Market Size is projected To Grow from USD 314.5 Million in 2024 to USD 562.7 Million by 2035, at a CAGR of 5.43% during the forecast period 2025–2035. The broaching machines market is growing due to increasing demand for high-precision machining, automotive and aerospace industry expansion, rising automation adoption, and the need for efficient manufacturing of complex internal and external shapes.

Introduction

The Broaching Machines Market Size encompasses the production and sale of machines used for the precise machining of complex shapes in metals and materials. It serves industries like automotive and aerospace, driven by demand for accuracy and efficient manufacturing. The growing need for precision machining in the metalworking, automotive, aerospace, and industrial machinery sectors is driving growth in the broaching machine market. These devices are excellent in accurately and efficiently creating intricate internal and exterior shapes, such as gears, splines, and keyways. Global market expansion is driven by rising investments in sophisticated machining technology and automation adoption. Automation and precise control innovations boost machine performance, allowing for increased output and better product quality. The demand for adaptable broaching machines that can handle a variety of materials and procedures is being driven by the trend of customisation in the automotive industry. Broaching machines are essential for precise engineering in a variety of industries and are widely employed in the production of engines, gearboxes and steering parts. Better design and control are made possible by emerging technologies like CNC, CAD, and specialised software, which further accelerate market expansion. All things considered, the market gains from the necessity for precise, effective, and flexible machining solutions to satisfy intricate and changing industrial demands.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Broaching Machines Market.

Broaching Machines Market Size & Statistics

- The Market Size for Broaching Machines Was Estimated to be worth USD 314.5 Million in 2024.

- The Market Size is Going to Expand at a CAGR of 5.43% between 2025 and 2035.

- The Global Broaching Machines Market Size is anticipated to reach USD 562.7 Million by 2035.

- North America is expected to generate the highest demand during the forecast period in the Broaching Machines Market

- Asia Pacific is expected to grow the fastest during the forecast period in the Broaching Machines Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the broaching machines market. The market for broaching machines in Asia is growing as a result of the abundance of manufacturing facilities in nations like China and India, which are bolstered by substantial industrial bases and low operating costs. The demand for sophisticated automotive technology has increased due to large expenditures in industrial hubs and infrastructure. The demand for accurate, effective broaching equipment is further increased by the expanding aerospace and defence industries. Manufacturers can increase production and product quality because of increased automation usage and competitive labour costs. Together, these elements propel rapid expansion and establish Asia as a major player in the world market for broaching machines.

North America is expected to generate the highest demand during the forecast period in the broaching machines market. Strong automobile manufacturing, particularly in the US, and a thriving aerospace and defence sector are the main drivers of the North American broaching machine market. The need for high-precision, high-performance broaching systems is rising as a result of the region's businesses prioritising automation and Industry 4.0 technologies. These cutting-edge devices improve precision and efficiency by integrating with intelligent production processes. North America is a crucial location for the adoption of broaching machines during the projection period due to the established aerospace sector's demand for dependable, high-quality components, which further drives market expansion.

Top 10 trends in the Broaching Machines Market

- Increasing Automation Integration

- Adoption of CNC and CAD Technologies

- Rising Demand in Automotive and Aerospace Sectors

- Development of High-Precision Broaching Machines

- Growing Use of Advanced Materials

- Customization and Versatility of Machines

- Implementation of Industry 4.0 and Smart Manufacturing

- Expansion in Emerging Markets

- Focus on Reducing Production Cycle Time

- Collaborations and R&D for Innovative Solutions

- Increasing Automation Integration

Manufacturers are integrating automation to enhance precision, reduce labour costs, and increase production speed. Automated broaching systems improve consistency and efficiency, meeting growing demands for high-quality components in industries like automotive and aerospace.

- Adoption of CNC and CAD Technologies

Complex shapes and tighter tolerances are made possible by the careful programming and design of broaching procedures made possible by CNC and CAD technologies. This method shortens manufacturing cycles, improves reproducibility, and lowers errors.

- Rising Demand in Automotive and Aerospace Sectors

The automotive and aerospace industries require complex, high-precision components, driving demand for broaching machines capable of producing parts like gears, splines, and keyways efficiently and accurately.

- Development of High-Precision Broaching Machines

Advances in machine design and control systems enable broaching machines to deliver higher precision and better surface finishes, supporting applications requiring stringent quality standards.

- Growing Use of Advanced Materials

The aerospace, automotive, and defence industries' demands have led to a growing use of broaching machines to process sophisticated, challenging-to-machine materials including composites and high-strength alloys.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the broaching machines market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 15 Companies Leading the Broaching Machines Market

- MITSUBISHI HEAVY INDUSTRIES, LTD.

- Accu-Cut

- Apex Broaching Systems

- Broaching Machine Specialties

- Colonial tool group inc.

- General Broach Company

- Hexagon Manufacturing Intelligence

- Ohio Broach & Machine Co.

- Pioneer Broach Co.

- The Ohio Broach & Machine Company

- Wentworth Engineering Ltd.

- Tecton Industries, Inc.

- CNC Broach Tool LLC

- Nidec Corporation

- Axsys Automation Ltd.

- Others

- MITSUBISHI HEAVY INDUSTRIES, LTD.

Headquarters: Tokyo, Japan

MITSUBISHI HEAVY INDUSTRIES, LTD. is one of the world's top industrial manufacturers. The corporation works in a variety of industries, such as infrastructure, shipbuilding, aircraft, defence, energy systems, and transportation. MHI employs more than 77,000 individuals across 256 consolidated group firms worldwide and 12 sites in Japan. Its reported revenues in fiscal 2025 were more than ¥5 trillion. Delivering cutting-edge technology and solutions that tackle intricate industrial and societal issues across numerous sectors, MHI prioritises innovation, sustainability, and growing its worldwide presence under the direction of President & CEO Eisaku Ito.

- Accu-Cut

Headquarters: Tavares, Florida, USA

Accu-Cut, a company founded by Scott Brockie in 1990, specialises in producing high-precision carpet and flooring cutting equipment. Their machinery is well known for increasing productivity, cutting down on labour, and boosting security in flooring operations. A variety of models, such as the Q7 and Q9, are available from Accu-Cut that are made to work with carpet, vinyl, and artificial turf, among other materials. The business offers flexible financing choices, training, and nationwide service. For flooring experts looking for dependable and cutting-edge solutions, Accu-Cut has established itself as a valued partner due to its dedication to quality and client satisfaction.

- Apex Broaching Systems

Headquarters: Warren, Michigan

Apex Broaching Systems has led the industry in the production of broaching machines. The company serves the automotive, aerospace, military, and consumer products industries by designing and manufacturing a broad range of broaching machines, cutting tools, fixtures, and automation solutions. Apex provides a range of tonnage capacities and stroke lengths for both horizontal and vertical broaching machines. The business offers complete turn-key solutions with an emphasis on accuracy and efficiency, and is well-known for its innovative automation and custom tooling. Apex continues to satisfy changing industrial machining needs worldwide with excellent customer service and engineering know-how.

- Broaching Machine Specialties

Headquarters: Novi, Michigan

One of America's top manufacturers of broaching systems is Broaching Machine Specialities (BMS). BMS was founded in 1946 and specialises in designing and manufacturing complete broaching machines for a range of industries, including the automotive, small arms, hand tool, agricultural, and marine sectors. The business provides a wide range of services, such as design consultancy, tooling, maintenance, and production broaching. BMS is a reliable partner in the broaching sector thanks to its dedication to accuracy and client satisfaction.

- Colonial tool group inc.

Headquarters: Windsor, Ontario

Founded in 1929, Colonial Tool Group Inc. is a well-known company with a focus on precision spindles, workholding fixtures, CNC broaching machines, and broaching tools. The company, which has more than 80 years of experience, provides tailored solutions for heavy equipment, automotive, and aerospace industries. Colonial Tool Group offers a wide range of services, including design, production, heat treatment, and in-field support, from locations in Canada, the United States, and Mexico. Their standing as a reliable partner in the machining sector has been cemented by their dedication to quality and innovation.

Are you ready to discover more about the Broaching Machines market?

The report provides an in-depth analysis of the leading companies operating in the global broaching machines market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes

Company Profiles

- MITSUBISHI HEAVY INDUSTRIES, LTD.

Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Accu-Cut

- Apex Broaching Systems

- Broaching Machine Specialties

- Colonial tool group inc.

- General Broach Company

- Hexagon Manufacturing Intelligence

- Ohio Broach & Machine Co.

- Pioneer Broach Co.

- The Ohio Broach & Machine Company

- Wentworth Engineering Ltd.

- Tecton Industries, Inc.

- CNC Broach Tool LLC

- Nidec Corporation

- Axsys Automation Ltd.

- Others

Conclusion

The Global Market Size for Broaching Machines is steadily growing due to technological developments and growing applications in the consumer goods, electronics, and automotive industries. Improved designs, robust materials, and more automation boost operational flexibility and manufacturing accuracy. Market expansion is fuelled by growing demand from manufacturing sectors, despite obstacles such as high production costs and competitive pressures. The vital role that broaching machines play in contemporary precision production across the globe is further supported by ongoing research and development, quality enhancements, and planned international expansion.

Need help to buy this report?