Top 40 Edge Additive Manufacturing Worldwide 2025: Strategic Insights & Market Trends

RELEASE DATE: Aug 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

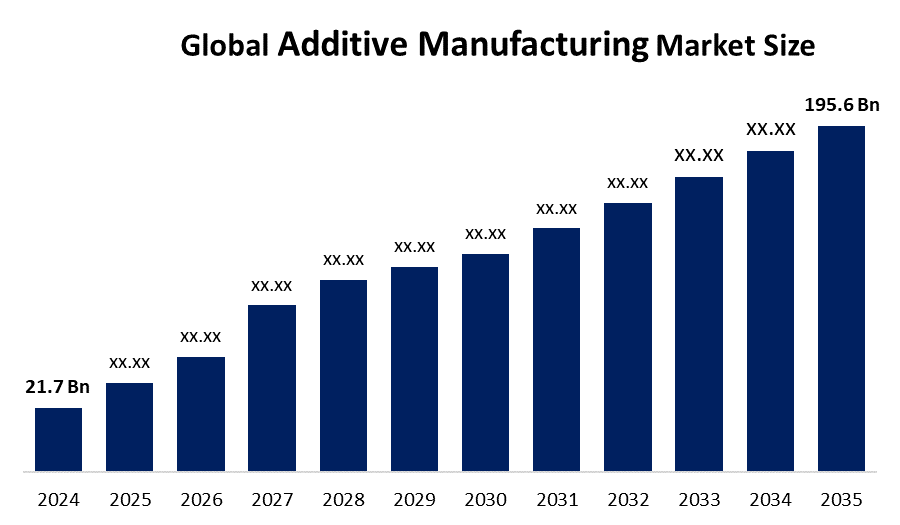

According to a research report published by Spherical Insights & Consulting, The Global Additive Manufacturing Market Size is projected to Grow from USD 21.7 Billion in 2024 to USD 195.6 Billion by 2035, at a CAGR of 22.13% during the forecast period 2025–2035. The market for additive manufacturing is expanding as a result of developments in material science, design freedom, lower production costs, quick prototyping, and growing use in the industrial, automotive, healthcare, and aerospace industries.

Introduction

The global additive manufacturing market refers to the industry that uses 3D printing technologies to create complex parts and products. Additive manufacturing, known as 3D printing, is a layer-by-layer manufacturing process that uses digital files to produce complex items. Unlike subtractive approaches, AM decreases material waste and increases design flexibility. It facilitates prototyping, structural development, and modelling, and reduces time-to-market, allowing for cost-effective production and competitive pricing. AM deployment includes installation, consultancy, support services, and intellectual property management. Key applications include healthcare, aerospace, and automotive, including tailored implants as well as lightweight aircraft and vehicle components. The additive manufacturing market is booming, thanks to rapid innovation, growing applications, and sophisticated 3D printing technology. A spike in mergers and acquisitions shows strategic initiatives to consolidate, gain access to new technology, and increase global competitiveness. Alternative rapid prototype processes, such as stereolithography or selective laser sintering, as well as CNC machining and injection moulding, all have an impact on the market. Despite these challenges, AM use is constantly increasing due to its benefits in innovation, efficiency, and customization across a variety of industrial sectors.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Additive Manufacturing Market.

Additive Manufacturing Market Size & Statistics

- The Market Size for Additive Manufacturing Was Estimated to be worth USD 21.7 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 22.13% between 2025 and 2035.

- The Global Additive Manufacturing Market Size is anticipated to reach USD 195.6 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Additive Manufacturing Market

- Asia-Pacific is expected to grow the fastest during the forecast period in the Additive Manufacturing Market.

Regional growth and demand

Asia-Pacific is expected to grow the fastest during the forecast period in the additive manufacturing market. The continuous advancements and improvements made by the region's reputable manufacturing enterprises, the additive manufacturing sector in the Asia Pacific is growing. Asia Pacific is rapidly emerging as a significant hub for the production of autos, medical equipment, and consumer electronics. The increasing urbanization of the area is also speeding up the adoption of 3D printing technologies. These factors work together to encourage the increased use of additive manufacturing across a range of industries, making the Asia Pacific a significant and growing market over the forecast period.

North America is expected to generate the highest demand during the forecast period in the additive manufacturing market. North America, led by the United States and Canada, has dominated the additive manufacturing business due to early adoption and significant technological developments. Key industries such as aerospace, automotive, and healthcare create a significant need for 3D printing applications. The region benefits from a strong network of universities, innovative companies, and government assistance, which promotes economic growth. Furthermore, the availability of skilled professionals and extensive service providers reinforces North America's dominant position. Europe is ranked second, with a huge geographic reach and substantial technological capability in additive manufacturing.

Top 10 trends in the Additive Manufacturing Market

- Metal 3D Printing Growth

- Advanced Materials Development

- Mass Customization

- Integration with AI and Machine Learning

- Hybrid Manufacturing Systems

- Sustainability Focus

- Increased Adoption in Aerospace and Defense

- Healthcare Innovations

- Expansion of On-Demand and Distributed Manufacturing

- Industry Consolidation and M&A Activity

1. Metal 3D Printing Growth

The aerospace, automotive, and medical industries are driving the rapid expansion of metal additive manufacturing. It improves performance and lowers manufacturing time and costs by making it possible to produce complicated, lightweight, and robust parts that are difficult to produce using traditional processes.

2. Advanced Materials Development

AM applications are expanding due to new printable materials like composites, ceramics, and biopolymers. These materials improve the usefulness, durability, and performance of parts, enabling companies to take on difficult problems and produce cutting-edge goods that satisfy particular environmental and mechanical standards.

3. Mass Customization

Additive manufacturing facilitates the creation of personalised goods, particularly in the consumer goods and healthcare industries prosthetics, implants. Because of this versatility, businesses may effectively produce unique designs and small batches without having to invest in expensive tooling upgrades.

4. Integration with AI and Machine Learning

AI improves quality control, minimises waste, and predicts failures to optimise AM design and production processes. Smarter, more effective manufacturing workflows are made possible by machine learning algorithms, which increase print speed and accuracy.

5. Hybrid Manufacturing Systems

Complex 3D printed shapes and precise finishing are made possible by combining additive and subtractive techniques on a single platform. This hybrid technique increases manufacturing capacities, decreases post-processing, and improves part quality.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the additive manufacturing market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 14 Companies Leading the Additive Manufacturing Market

- Optomec, Inc.

- 3D Systems, Inc.

- Arcam AB

- 3DCeram

- Canon, Inc.

- Autodesk, Inc.

- EnvisionTec, Inc.

- Dassault Systemes

- ExOne

- EOS (Electro Optical Systems) GmbH

- HP Inc.

- GE Additive

- Materialise NV

- madeinspace.us

- Others

1. Optomec, Inc.

Headquarters: Headquarters: Albuquerque, New Mexico, USA

The top suppliers of industrial-scale additive manufacturing solutions, Optomec, Inc., focusses on metal and electronics 3D printing systems. Prominent for its unique LENS and Aerosol Jet® technologies, Optomec facilitates the manufacturing and restoration of intricate metal parts and incredibly delicate electrical circuits. The company serves elite clientele in electronics, aerospace, defence, and healthcare, with more than 600 systems deployed worldwide. In order to provide affordable, digitally integrated solutions that support Industry 4.0 and next-generation manufacturing processes, Optomec keeps pushing innovation through strategic R&D expenditures.

2. 3D Systems, Inc.

Headquarters: Rock Hill, South Carolina, USA

Chuck Hull, the inventor of stereolithography (SLA), created 3D Systems, Inc. in 1986. The company is a leader in additive manufacturing worldwide. The business provides a wide range of 3D printing methods, such as FDM, MJP, SLA, SLS, and DMP (metal). Along with a wide variety of materials and on-demand production services, it also offers sophisticated software tools like 3D Sprint and 3DXpert. End-to-end digital workflows from prototyping to production are made possible by 3D systems, which serve sectors like aerospace, healthcare, dentistry, automotive, and defence. Because of its ongoing innovation, it is positioned to play a significant role in the development of digital manufacturing.

3. Arcam AB

Headquarters: Molndal, Sweden

Established in 1997, Arcam AB is a Swedish firm that specialises in metal additive manufacturing using Electron Beam Melting (EBM) technology. Arcam, which is now a part of GE Additive, creates sophisticated EBM systems for the production of fully dense, high-performance metal components, mostly for the automotive, medical, and aerospace sectors. Its in-house expertise makes it possible to use materials like titanium alloys to produce intricate components. Arcam runs DiSanto Technologies (implant manufacturing) and AP&C (metal powder production) in addition to EBM equipment. Arcam continues to be a leader in premium metal 3D printing solutions because of continuous R&D investments, including a sizable Centre of Excellence in Sweden.

4. 3DCeram

Headquarters: Bonnac-la-Cote, France

3DCeram is a prominent supplier of ceramic additive manufacturing technologies, with a focus on high-performance technical ceramics using stereolithography (SLA). It provides systems from prototyping to large-scale production, including the C1000 FLEXMATIC and C3600 ULTIMATE, and serves sectors like semiconductors, biomedical, and aerospace. For increased adaptability, its sophisticated M.A.T. (Multi Additive Technology) platform incorporates several AM techniques, including FFF and DIW. TIWARI Scientific Instruments was recently acquired by 3DCeram, which is now a part of the Sinto Group, to increase its hybrid manufacturing capabilities as part of its ongoing efforts to develop its Industry 4.0 ecosystem.

5. Canon, Inc.

Headquarters: Ota, Tokyo, Japan

Canon Inc. is a well-known international company that specialises in optical and image devices, including medical imaging equipment, printers, scanners, and cameras. Canon, which was founded in 1937, invented the first camera with a built-in microcomputer. In addition to consumer electronics, Canon provides services to the semiconductor manufacturing, office solutions, and healthcare sectors. The business makes significant R&D investments to develop new technologies in digital imaging, printing, and medical diagnostics. Canon is a significant participant in both the consumer and industrial markets thanks to its extensive range of products and global reach. It also promotes digital transformation and sustainable business practices while fostering innovation in image solutions globally.

Are you ready to discover more about the Additive Manufacturing market?

The report provides an in-depth analysis of the leading companies operating in the global additive manufacturing market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Optomec, Inc.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- 3D Systems, Inc.

- Arcam AB

- 3DCeram

- Canon, Inc.

- Autodesk, Inc.

- EnvisionTec, Inc.

- Dassault Systemes

- ExOne

- EOS (Electro Optical Systems) GmbH

- HP Inc.

- GE Additive

- Materialise NV

- madeinspace.us

- Others

Conclusion

The market for additive manufacturing is growing quickly due to developments in printing technology, materials, and AI-driven process optimization. Growth is fuelled by the growing need for sophisticated, lightweight, and customised parts in sectors like automotive, healthcare, and aerospace. Material quality, compliance, and production scalability are being improved via strategic partnerships between manufacturers, regulatory agencies, and technology developers. More accurate, effective, and sustainable manufacturing processes are made possible by advancements in hardware and software. Additive manufacturing develops to provide adaptable, affordable solutions that enhance product performance, cut waste, and speed time-to-market globally as sectors place a higher priority on digital transformation and agility.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?