Top 30 Single Chamber Vacuum Furnace Market Companies in Globe 2025: Statistics View by Spherical Insights and Consulting

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

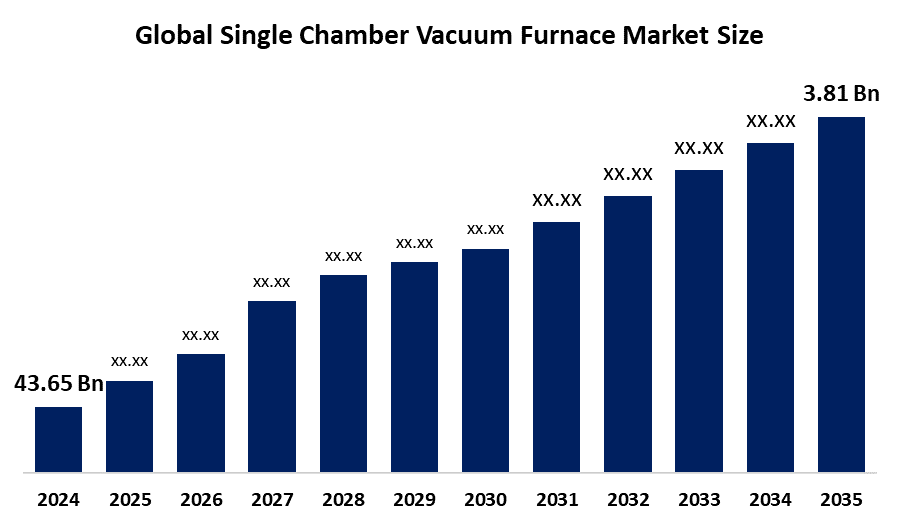

According to a research report published by Spherical Insights & Consulting, The Global Single Chamber Vacuum Furnace Market Size is projected To Grow from USD 1.89 Billion in 2024 to USD 3.81 Billion by 2035, at a CAGR of 6.58 % during the forecast period 2025–2035. The single chamber vacuum furnace market presents opportunities in aerospace, automotive, and energy sectors, driven by demand for advanced heat treatment, lightweight materials, additive manufacturing, precision engineering, and sustainable production technologies ensuring efficiency and reliability.

Introduction

The sSngle Chamber Vacuum Furnace Market Size is gaining traction as industries demand advanced heat treatment solutions for high-performance materials. These furnaces provide controlled environments for processes like brazing, annealing, sintering, and quenching, ensuring superior quality, consistency, and minimal contamination. Widely used in aerospace, automotive, medical, and energy sectors, they enable the production of lightweight components, precision-engineered parts, and durable alloys. Growing adoption of additive manufacturing and advanced materials such as titanium and superalloys is further fueling demand. With rising emphasis on energy efficiency, automation, and sustainability, single chamber vacuum furnaces are becoming essential to modern industrial manufacturing and technological innovation.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Single Chamber Vacuum Furnace market.

Single Chamber Vacuum Furnace Market Size & Statistics

- The Market Size for Single Chamber Vacuum Furnace Was Estimated to be Worth USD 1.89 Billion in 2024.

- The Market Size is going to Expand at a CAGR of 6.58 % Between 2025 and 2035.

- The Global Single Chamber Vacuum Furnace Market Size is Anticipated to Reach USD 3.81 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Single Chamber Vacuum Furnace Market.

- Asia Pacific is expected to grow the fastest during the forecast period in the Single Chamber Vacuum Furnace Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the Single Chamber Vacuum Furnace market. The expanding automotive and aerospace sectors, increasing manufacturing investments, and swift industrialization are the key drivers of market growth in this region. At the forefront in this area are countries such as China, India, and Japan, where state initiatives aimed at enhancing local manufacturing abilities and technological innovations are driving demand.

North America is expected to generate the highest demand during the forecast period in the Single Chamber Vacuum Furnace market. The embrace of contemporary manufacturing technology and continuous funding in research and development have positioned the United States, especially, as a key player in market expansion. The North American market is expected to grow consistently due to technological advancements and an increasing emphasis on sustainability and energy efficiency.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Single Chamber Vacuum Furnace market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 5 Trends in Single Chamber Vacuum Furnace Market

1. Rising Demand in Aerospace and Automotive Sectors

The aerospace and automotive industries are driving significant demand for single chamber vacuum furnaces due to their need for advanced heat treatment of lightweight and high-performance materials. Components such as turbine blades, engine parts, and structural alloys require precision brazing, annealing, and sintering to meet strict durability and performance standards. As both industries push for fuel efficiency and reduced emissions, the use of titanium and superalloys has expanded, further boosting furnace adoption. Single chamber furnaces ensure consistency, reduced oxidation, and superior mechanical properties, making them critical in producing reliable, high-quality parts for these rapidly evolving sectors.

2. Integration of Automation and Smart Technologies

The adoption of Industry 4.0 is influencing the single chamber vacuum furnace market, with growing integration of automation, IoT, and digital monitoring systems. Smart furnaces now feature advanced sensors, data analytics, and predictive maintenance tools that enable real-time process monitoring and optimization. Automation reduces human error, enhances operational efficiency, and supports repeatability in heat treatment processes. Manufacturers are also using AI-driven insights to adjust furnace parameters for energy savings and improved outcomes. This trend reflects the shift toward digitalized manufacturing ecosystems, where connected furnaces contribute to higher productivity, cost efficiency, and smarter decision-making in industrial operations worldwide.

3. Increasing Use in Additive Manufacturing

Additive manufacturing, or 3D printing, is expanding rapidly, and single chamber vacuum furnaces are becoming essential for post-processing of printed metal components. Heat treatment processes such as stress relieving, sintering, and hot isostatic pressing (HIP) are critical to improving mechanical properties and microstructure of additively manufactured parts. Aerospace, medical, and automotive sectors are increasingly relying on furnaces to ensure that 3D-printed titanium, aluminum, and superalloy parts meet strict performance standards. The trend underscores the growing synergy between advanced manufacturing techniques and high-precision vacuum furnaces, positioning them as indispensable tools in the industrialization of additive manufacturing technologies.

4. Focus on Energy Efficiency and Sustainability

Sustainability is becoming a core driver in the single chamber vacuum furnace market. With rising energy costs and strict environmental regulations, manufacturers are investing in energy-efficient furnaces that reduce operational costs and carbon footprints. Modern furnaces incorporate advanced insulation, optimized heating elements, and power-saving controls to minimize energy consumption. Additionally, the development of eco-friendly processes, such as low-emission quenching and reduced gas usage, aligns with industry-wide sustainability goals. Companies adopting greener vacuum furnace technologies not only enhance their operational efficiency but also strengthen their market position by meeting customer and regulatory demands for cleaner, sustainable manufacturing practices.

5. Expansion in Medical and Energy Applications

The medical and energy industries are increasingly adopting single chamber vacuum furnaces for their precision and reliability in processing advanced materials. In the medical field, these furnaces support the production of surgical instruments, implants, and prosthetics, requiring contamination-free and durable finishes. In energy, they are used in heat treatment of turbines, fuel cells, and nuclear components that demand high performance under extreme conditions. As both industries expand, the need for precise thermal processing grows, driving furnace demand. This trend highlights the diversification of applications, making single chamber vacuum furnaces vital beyond traditional sectors and into emerging high-growth industries.

Top 15 Companies Leading the Single Chamber Vacuum Furnace Market

- Nabertherm GmbH

- Ipsen International GmbH

- SECO/WARWICK S.A.

- L&L Special Furnace Co., Inc.

- Tenova S.p.A.

- ECM Technologies

- TAV Vacuum Furnaces S.p.A.

- Koyo Thermo Systems Co., Ltd.

- Advanced Vacuum Systems, Inc.

- Solar Manufacturing Inc.

- ALD Vacuum Technologies GmbH

- Centorr Vacuum Industries

- Thermal Technology LLC

- IHI Corporation

- Others

1. Nabertherm GmbH

Headquarters: Lilienthal, Germany

Nabertherm GmbH is a leading manufacturer of industrial furnaces and heat treatment systems, including single chamber vacuum furnaces. The company serves industries such as aerospace, automotive, medical, and research institutions, offering highly efficient, reliable, and customizable solutions. Nabertherm emphasizes innovation, providing furnaces with precise temperature control, advanced insulation, and energy-efficient designs. Its products support processes like annealing, sintering, brazing, and stress relieving. With a strong global distribution network, the company focuses on sustainability and automation, integrating digital control systems for enhanced productivity. Nabertherm’s reputation for quality and engineering excellence makes it a trusted partner in industrial thermal processing worldwide.

2. Ipsen International GmbH

Headquarters: Kleve, Germany

Ipsen International GmbH is a global leader in thermal processing technology, specializing in vacuum furnaces, including single chamber designs. The company offers innovative heat treatment solutions for industries such as aerospace, automotive, and energy, ensuring precision and consistency in processes like carburizing, annealing, and quenching. Ipsen’s furnaces are equipped with advanced digital controls, IoT integration, and energy-efficient systems to meet Industry 4.0 standards. With manufacturing facilities in Europe, North America, and Asia, Ipsen provides global reach and localized service. Its focus on sustainability, process optimization, and customer-centric solutions positions it as a pioneer in advanced heat treatment technologies.

3. SECO/WARWICK S.A.

Headquarters: Swiebodzin, Poland

SECO/WARWICK S.A. is a global provider of advanced heat treatment equipment, including single chamber vacuum furnaces. Known for innovation, the company delivers solutions for aerospace, defense, automotive, and energy industries. Its furnaces are designed for processes such as brazing, sintering, and hardening, offering precision, reliability, and efficiency. SECO/WARWICK emphasizes digitalization, automation, and energy efficiency in its designs, integrating smart technologies for real-time monitoring and predictive maintenance. With operations in over 70 countries, the company has a strong global presence and R&D capabilities. Its commitment to sustainable manufacturing and tailored solutions strengthens its position as a leader in vacuum furnace technology.

4. L&L Special Furnace Co., Inc.

Headquarters: Aston, Pennsylvania, United States

L&L Special Furnace Co., Inc. specializes in designing and manufacturing industrial furnaces and ovens, including single chamber vacuum furnaces. Serving aerospace, automotive, and medical sectors, the company provides high-quality thermal processing solutions tailored to customer requirements. L&L furnaces are known for their precise temperature uniformity, robust construction, and user-friendly controls. The company focuses on flexibility, offering custom-engineered solutions for specialized heat treatment applications such as annealing, brazing, and tempering. L&L emphasizes service, reliability, and technical expertise, ensuring long-term customer satisfaction. Its strong U.S. manufacturing base and growing international reach make it a trusted name in specialized furnace technology.

5. Tenova S.p.A.

Headquarters: Castellanza, Italy

Tenova S.p.A., part of the Techint Group, is a leading provider of sustainable solutions for the metals and mining industries, including advanced heat treatment technologies like single chamber vacuum furnaces. The company delivers innovative systems for processes such as carburizing, annealing, and brazing, serving aerospace, automotive, and heavy industries. Tenova emphasizes energy efficiency, digital integration, and eco-friendly designs, aligning with global sustainability goals. Its furnaces are engineered for reliability, precision, and reduced operational costs, meeting the demands of modern manufacturing. With a strong international presence and focus on R&D, Tenova continues to be a global leader in thermal processing solutions.

Are you ready to discover more about the Single Chamber Vacuum Furnace market?

The report provides an in-depth analysis of the leading companies operating in the global Single Chamber Vacuum Furnace market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Nabertherm GmbH.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Ipsen International GmbH

- SECO/WARWICK S.A.

- L&L Special Furnace Co., Inc.

- Tenova S.p.A.

- ECM Technologies

- TAV Vacuum Furnaces S.p.A.

- Koyo Thermo Systems Co., Ltd.

- Advanced Vacuum Systems, Inc.

- Solar Manufacturing Inc.

Conclusion

The Single Chamber Vacuum Furnace Market Size is set to play a critical role in advancing modern industrial manufacturing. With growing applications across aerospace, automotive, medical, and energy sectors, these furnaces enable precision, durability, and sustainability in material processing. The integration of smart technologies, automation, and energy-efficient designs is reshaping the industry while supporting global sustainability goals. Rising demand in additive manufacturing and emerging industries further expands growth potential. As companies continue investing in innovation and customization, single chamber vacuum furnaces will remain essential for achieving higher productivity, compliance, and technological excellence in a rapidly evolving industrial landscape worldwide.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?