Top 30 Polymer 3D Printing Equipment Companies in Globe 2025: Statistics View by Spherical Insights And Consulting.

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

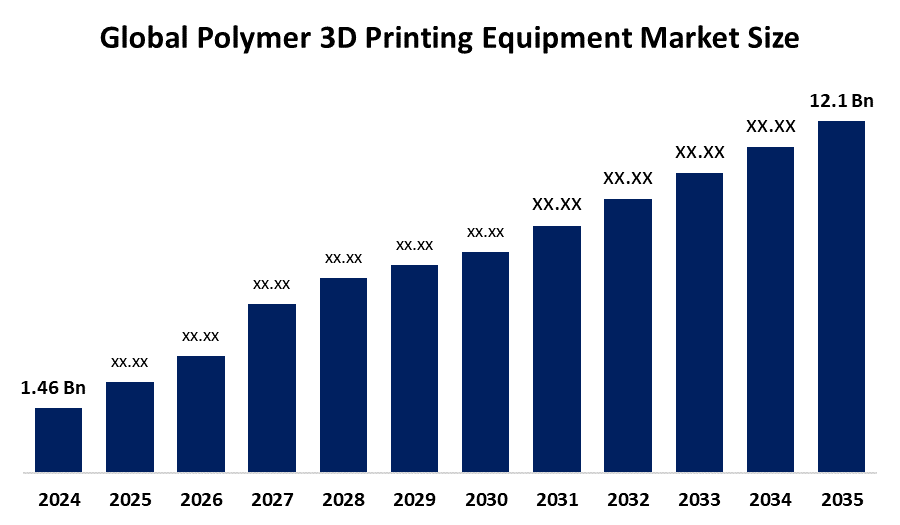

According to a research report published by Spherical Insights & Consulting, The Global Polymer 3D Printing Equipment Market Size is projected to Grow from USD 1.46 Billion in 2024 to USD 12.1 Billion by 2035, at a CAGR of 21.2 % during the forecast period 2025–2035. The Polymer 3D Printing Equipment market offers future opportunities through advancements in lightweight materials, customization demand, adoption in healthcare, automotive, and aerospace, sustainable manufacturing, cost reduction, rapid prototyping, and expanding applications across industrial and consumer sectors.

Introduction

The Polymer 3D Printing Equipment Market Size is experiencing rapid growth driven by increasing demand for advanced manufacturing technologies across industries. Polymer-based 3D printers enable cost-effective, lightweight, and customizable solutions for diverse applications in automotive, aerospace, healthcare, and consumer goods. Governments and private enterprises are investing in additive manufacturing to enhance production efficiency, sustainability, and innovation. Advancements in material science and printer technology are expanding capabilities, from rapid prototyping to large-scale industrial production. With the rising need for sustainable solutions and on-demand manufacturing, the market is poised to offer significant opportunities, transforming traditional production methods and creating a dynamic growth landscape.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Polymer 3D Printing Equipment market.

Polymer 3D Printing Equipment Market Size & Statistics

- The Market Size for Polymer 3D Printing Equipment Was Estimated to be Worth USD 1.46 Billion in 2024.

- The Market Size is going to Expand at a CAGR of 21.2 % Between 2025 and 2035.

- The Global Polymer 3D Printing Equipment Market Size is Anticipated to Reach USD 12.1 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Polymer 3D Printing Equipment market.

- North America is expected to grow the fastest during the forecast period in the Polymer 3D Printing Equipment market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Polymer 3D Printing Equipment market. North America is expected to grow the fastest due to strong technological innovation, high adoption in aerospace, automotive, and healthcare sectors, significant R&D investments, presence of leading 3D printing companies, and government support for advanced manufacturing and digital transformation initiatives.

Asia Pacific is expected to generate the highest demand during the forecast period in the Polymer 3D Printing Equipment market. Asia-Pacific is expected to generate the highest demand due to rapid industrialization, strong government initiatives, and growing adoption of additive manufacturing in automotive, aerospace, and healthcare sectors. Cost advantages, rising R&D activities, and expanding local manufacturers further strengthen regional market growth.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Polymer 3D Printing Equipment market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 5 Trends in Polymer 3D Printing Equipment Market

1. Advancements in Material Innovation

The market is witnessing rapid innovation in polymer materials, enabling stronger, more durable, and versatile applications. High-performance polymers like PEEK, PEKK, and reinforced composites are expanding the scope of 3D printing in aerospace, automotive, and medical industries. These advanced polymers offer heat resistance, biocompatibility, and superior mechanical strength, making them ideal for critical applications such as implants, lightweight vehicle components, and customized aerospace parts. As research in material science accelerates, manufacturers are offering specialized polymers tailored for unique industry requirements. This trend not only boosts adoption but also enhances the value proposition of polymer 3D printing technologies globally.

2. Growing Adoption in Healthcare

Healthcare is emerging as one of the most promising sectors for polymer 3D printing equipment. The ability to manufacture patient-specific medical devices, implants, prosthetics, and surgical models is revolutionizing personalized medicine. Biocompatible polymers enable safe and effective production of customized solutions that improve patient outcomes. Furthermore, dental applications, anatomical models for surgical training, and drug delivery devices are creating significant demand. Hospitals, research institutions, and medical device manufacturers are increasingly adopting 3D printing to reduce costs and lead times while enhancing precision. This trend is expected to accelerate with rising demand for affordable, customized, and efficient healthcare solutions worldwide.

3. Integration with Industry 4.0

Polymer 3D printing equipment is becoming a vital part of Industry 4.0, with integration of AI, IoT, robotics, and digital twins into additive manufacturing workflows. Smart 3D printers enable real-time monitoring, predictive maintenance, and automation, leading to improved efficiency and cost savings. Digital connectivity allows manufacturers to streamline production, reduce errors, and ensure consistent quality in polymer parts. Cloud-based platforms are further enabling remote design, collaboration, and on-demand production. This integration supports mass customization, rapid prototyping, and supply chain optimization. The convergence of 3D printing with Industry 4.0 is driving innovation and reshaping traditional manufacturing ecosystems across industries.

4. Sustainable Manufacturing Practices

Sustainability is a key trend influencing polymer 3D printing equipment adoption. Additive manufacturing reduces material waste compared to traditional subtractive methods, aligning with global sustainability goals. Increasing use of recyclable and bio-based polymers is gaining traction, addressing environmental concerns. Companies are developing eco-friendly filaments and resins derived from renewable sources, supporting circular economy practices. Furthermore, on-demand local production enabled by 3D printing minimizes transportation emissions and energy consumption. As industries prioritize green initiatives, polymer 3D printing is positioned as a sustainable solution that balances cost-effectiveness with environmental responsibility, encouraging wider acceptance in global manufacturing and consumer applications.

5. Expansion in Consumer and Industrial Applications

Polymer 3D printing is expanding beyond prototyping into end-use applications across industries and consumer markets. Automotive and aerospace manufacturers use it for lightweight structural components, while healthcare leverages it for customized implants and devices. Consumer markets are embracing polymer 3D printing for fashion, footwear, and personalized products. Small and medium enterprises (SMEs) are increasingly adopting affordable polymer 3D printers for rapid prototyping and small-batch production. The versatility and cost-efficiency of polymer-based equipment are enabling businesses to innovate faster and reduce time-to-market. This broadening application base is driving global demand and transforming the market into a mainstream manufacturing technology.

Top 20 Companies Leading the Polymer 3D Printing Equipment Market

- Stratasys Ltd.

- 3D Systems Corporation

- EOS GmbH

- Materialise NV

- HP Inc.

- GE Additive

- EnvisionTEC GmbH

- Formlabs Inc.

- SLM Solutions Group AG

- Ultimaker BV

- Markforged Inc.

- Carbon, Inc.

- XYZprinting, Inc.

- Proto Labs, Inc.

- Renishaw plc

- Desktop Metal, Inc.

- ExOne Company

- Voxeljet AG

- Tiertime Corporation

- Raise3D Technologies, Inc.

1. Stratasys Ltd.

Headquarters: Eden Prairie, Minnesota, U.S. (also Rehovot, Israel)

Stratasys, founded in 1989 by Scott Crump, is a leading polymer-based 3D printing company. It produces systems using Fused Deposition Modeling (FDM), PolyJet, stereolithography, and other additive manufacturing technologies. The company serves industries including aerospace, automotive, healthcare, and consumer goods, offering 3D printers, materials (filaments, photopolymers, etc.), and related software & services. It also operates Stratasys Direct (service / parts on demand) and provides tools like GrabCAD software. Stratasys emphasizes high-performance thermoplastics (ABS, PC, polyetherimide, etc.) and complex geometries for both prototyping and end-use parts.

2. 3D Systems Corporation

Headquarters: Rock Hill, South Carolina, U.S.

3D Systems, established in 1986 by Chuck Hull (inventor of stereolithography), is a pioneer of additive manufacturing. It offers a broad portfolio: SLA (stereolithography), SLS (selective laser sintering), metal printing (DMP), material jetting, polymer extrusion, and software, materials, and services. Its offerings include hardware, software tools, printed parts (prototypes to low-volume production), and digital manufacturing workflows. Key markets are healthcare, aerospace, dental, automotive, and industrial goods. The company also supports customers through design software, scanning, simulation, and additive manufacturing services globally.

3. EOS GmbH (Electro-Optical Systems)

Headquarters: Krailling, near Munich, Germany

Founded in 1989 in Gräfelfing (now office in Krailling), EOS is a major industrial 3D printing company focused on both polymer and metal additive manufacturing. It offers end-to-end solutions: 3D printers, materials, process parameters, software, training, and service. It is known for laser-sintering systems and high-performance materials, especially for demanding industrial applications that require high material performance, precision, and repeatability. EOS invests in innovation (new polymer/metal materials), serves sectors like aerospace, automotive, tooling, medical implants, and emphasizes responsible and sustainable manufacturing.

4. Materialise NV

Headquarters: Leuven, Belgium

Materialise, founded in 1990, is a Belgian company combining 3D printing services, software development, and medical-oriented applications. Their operations are organised into three main segments: Software (e.g. tools for design, build preparation, image-based modelling), Medical (patient-specific implants, surgical planning tools), and Manufacturing (prototyping & production of parts). They serve industries including healthcare, automotive, aerospace, consumer goods, and art & design. Materialise also partners with printer manufacturers, CAD/CAM/PLM firms, and maintains service centres in multiple countries globally. They are known for being among the pioneers in digitally converting medical imaging into models and parts.

5. HP Inc.

Headquarters: Palo Alto, California, U.S.

HP Inc., re-formed in 2015 from the split of Hewlett-Packard, is a global technology company producing personal computers, printers, scanners, and increasingly, 3D printing and digital manufacturing solutions. Their 3D printing arm includes technologies like Multi Jet Fusion (MJF), Metal Jet, and they invest in R&D such as the 3D Printing & Digital Manufacturing Center of Excellence in Barcelona. Their offerings aim at both prototyping and production-grade parts, and they emphasize scalability, sustainability, and expanding materials. HP works with partners to advance material development, workflow software, and digital manufacturing infrastructure.

Are you ready to discover more about the Polymer 3D Printing Equipment market?

The report provides an in-depth analysis of the leading companies operating in the global Polymer 3D Printing Equipment market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Stratasys Ltd.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- 3D Systems Corporation

- EOS GmbH

- Materialise NV

- HP Inc.

- GE Additive

- EnvisionTEC GmbH

- Formlabs Inc.

- SLM Solutions Group AG

- Ultimaker BV

Conclusion

The Polymer 3D Printing Equipment market is evolving as a transformative force across multiple industries, reshaping how products are designed, developed, and manufactured. With advancements in material innovation, integration with digital technologies, and growing applications in sectors such as healthcare, aerospace, automotive, and consumer goods, the market is poised for remarkable growth. Regional dynamics highlight Asia-Pacific’s strong demand and North America’s rapid technological progress, reinforcing the market’s global potential. Companies that embrace sustainability, invest in R&D, and adapt to shifting industry needs will be best positioned to capture emerging opportunities and lead the future of additive manufacturing.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?