Top 25 Companies in Insulated Metal Substrate Market in the World in 2025: Market Research Report (2024–2035).

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

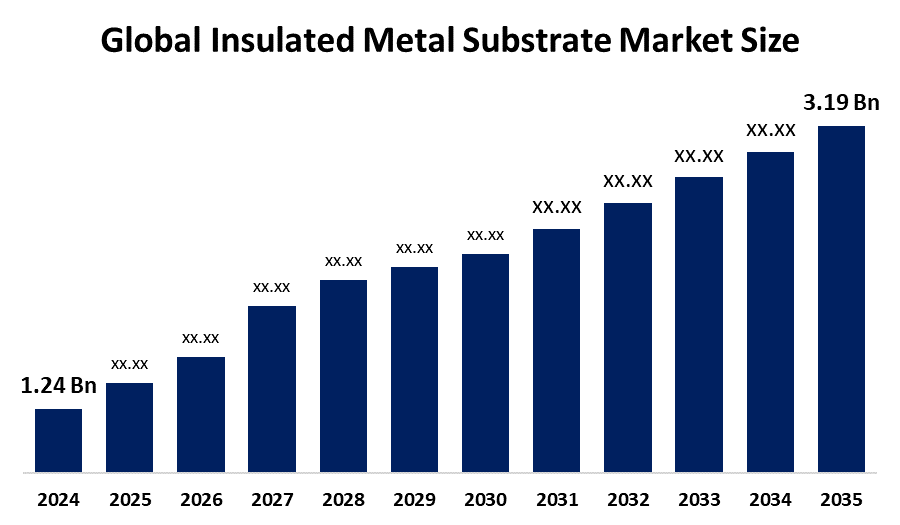

According to a research report published by Spherical Insights & Consulting, The Global Insulated Metal Substrate Market Size is projected To Grow from USD 1.24 Billion in 2024 to USD 3.19 Billion by 2035, at a CAGR of 8.97 % during the forecast period 2025–2035. The Insulated Metal Substrate market offers future opportunities in LED lighting, power electronics, and automotive sectors, driven by high thermal conductivity, lightweight design, energy efficiency, and growing demand for reliable heat-dissipation solutions.

Introduction

The Insulated Metal Substrate (IMS) Market Size is witnessing significant growth due to increasing demand for efficient thermal management solutions across electronics, automotive, and LED lighting industries. IMS combines high-performance metals with dielectric layers to enhance heat dissipation, electrical insulation, and mechanical stability in compact electronic assemblies. Its applications include power modules, LED boards, automotive electronics, and industrial devices, where reliability and energy efficiency are critical. Rising adoption of electric vehicles, renewable energy systems, and miniaturized electronic devices further drives demand. Innovations in materials, cost-effective manufacturing, and sustainability are shaping the IMS market, positioning it for robust growth in the coming years.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Insulated Metal Substrate market.

Insulated Metal Substrate Market Size & Statistics

- The Market Size for Insulated Metal Substrate Was Estimated to be Worth USD 1.24 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 8.97 % Between 2025 and 2035.

- The Global Insulated Metal Substrate Market Size is Anticipated to Reach USD 3.19 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Insulated Metal Substrate Market.

- North America is expected to grow the fastest during the forecast period in the Insulated Metal Substrate Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Insulated Metal Substrate market. This growth is driven by increasing adoption in high-performance electronics, automotive, and LED lighting applications. The region benefits from advanced manufacturing infrastructure, strong R&D investments, and early adoption of innovative IMS technologies. Growing demand for energy-efficient devices, electric vehicles, and compact electronic systems further accelerates market expansion.

Asia Pacific is expected to generate the highest demand during the forecast period in the Insulated Metal Substrate market. This region's dominance is driven by rapid industrialization, particularly in countries like China, India, and Japan, which are significant producers and consumers of IMS materials. The growing automotive sector, especially the rise of electric vehicles, and the increasing demand for high-performance electronics contribute to the region's market leadership.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Insulated Metal Substrate market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 5 Trends in Insulated Metal Substrate Market

1. Rising Adoption in LED Lighting

IMS is increasingly used in LED lighting due to its excellent thermal conductivity and electrical insulation properties. As LEDs become the standard in commercial, industrial, and residential lighting, IMS helps dissipate heat efficiently, enhancing device lifespan and performance. Manufacturers are integrating IMS into high-power LEDs, street lighting, and automotive lighting modules. The shift toward energy-efficient and sustainable lighting solutions fuels this trend. Additionally, IMS enables miniaturization of LED modules, supporting compact and flexible designs, which aligns with the growing demand for smart and IoT-enabled lighting systems worldwide.

2. Growing Use in Power Electronics and Automotive Applications

Power electronics, electric vehicles (EVs), and hybrid vehicles rely heavily on IMS for thermal management and electrical insulation. IMS substrates are used in inverters, converters, battery management systems, and motor controllers to maintain efficiency under high power loads. With the accelerating EV market and increasing electronic component density, the demand for high-performance IMS materials is rising. IMS ensures reliability, reduces thermal stress, and supports compact designs in automotive electronics. This trend is reinforced by global efforts to electrify transportation and adopt sustainable mobility solutions, driving investment in advanced substrate technologies.

3. Miniaturization and High-Density Electronic Circuits

The trend toward smaller, high-performance electronic devices is boosting IMS demand. IMS provides a compact platform for mounting components while efficiently managing heat, crucial in smartphones, medical devices, industrial controllers, and computing equipment. High-density circuit integration and thermal management are essential for maintaining performance and reliability in miniaturized electronics. IMS allows designers to optimize space without compromising electrical insulation or thermal efficiency. As industries push for thinner, lighter, and more powerful devices, IMS adoption is expected to grow, enabling manufacturers to meet consumer and industrial requirements for compact, high-performance electronic assemblies.

4. Integration with Advanced Manufacturing and Industry 4.0

IMS manufacturing is increasingly integrated with automated assembly, robotic handling, and smart production technologies. Industry 4.0 practices, including real-time monitoring, predictive maintenance, and precision manufacturing, enhance product quality and reduce defects. Advanced processes such as laser structuring, high-precision lamination, and automated coating improve IMS consistency and reliability. Electronics, automotive, and LED industries benefit from high-throughput, automated IMS production. This trend supports scalable manufacturing and faster time-to-market for complex electronic assemblies. The convergence of IMS technology with digital manufacturing ensures efficient, sustainable, and consistent production, strengthening its role in next-generation electronics and high-performance applications.

5. Demand for High-Thermal Conductivity and Eco-Friendly Materials

Thermal management challenges are driving demand for IMS with superior thermal conductivity, low coefficient of thermal expansion, and environmentally friendly formulations. Manufacturers focus on lead-free, halogen-free, and recyclable IMS substrates to comply with global regulations like RoHS and REACH. High-performance IMS reduces energy losses, improves system efficiency, and supports sustainability goals in electronics, automotive, and renewable energy sectors. Innovations in substrate materials, such as metal cores with advanced polymeric dielectrics, enhance thermal performance while maintaining electrical insulation. The combination of efficiency, reliability, and eco-friendliness positions IMS as a preferred solution in modern, sustainable electronics manufacturing.

Top 17 Companies Leading the Insulated Metal Substrate Market

- NHK

- AT&S

- Henkel

- Ventec

- WürthElektronik GmbH

- NCAB

- CML

- Denka

- ECM Group

- Guangdong CH Laminates Technology Corp Ltd

- DK Thermal

- AI Technology

- Technoboards KRONACH GmbH

- Segue Electronics

- PragoBoard s.r.o.

- TCLAD Inc

- DK-Daleba

1. NHK SPRING Co., Ltd.

Headquarters: Yokohama, Japan

NHK SPRING Co., Ltd. is a leading Japanese manufacturer specializing in automotive components, suspension springs, and electronic parts. Established in 1939, the company has expanded into Insulated Metal Substrates (IMS), utilizing materials like aluminum, copper, and iron to enhance heat dissipation and mechanical strength in electronic applications. NHK’s IMS products are widely used in automotive electronics, power modules, and LED lighting systems, offering solutions that meet growing demand for efficient thermal management in compact devices. Known for innovation and quality, NHK continues to provide high-performance IMS solutions for diverse industries worldwide.

2. AT&S (Austria Technologie & Systemtechnik AG)

Headquarters: Leoben, Austria

AT&S is a global leader in high-end printed circuit boards (PCB) and IC substrate manufacturing. Founded in 1987, the company specializes in advanced PCB technologies for automotive, industrial, medical, and communication applications. AT&S offers thermally enhanced PCBs and IMS solutions that efficiently dissipate heat, protecting electronic circuits from overheating. Their products address challenges from increasing miniaturization and complexity in electronics. With cutting-edge production capabilities and innovation-focused R&D, AT&S provides reliable, high-performance IMS products that meet the demands of modern electronic systems across multiple industries.

3. Henkel AG & Co. KGaA

Headquarters: Düsseldorf, Germany

Henkel is a global leader in adhesives, sealants, and surface treatment technologies. The company provides Thermal-Clad Insulated Metal Substrates (IMS), designed for efficient thermal management of semiconductor devices. Henkel’s IMS solutions reduce thermal impedance and conduct heat effectively, enhancing the performance and reliability of electronic components. The company leverages its deep expertise in material science and innovation to produce high-quality IMS solutions for automotive, industrial, and electronic applications. Henkel continues to advance eco-friendly, durable, and high-performance crosslinking technologies, making it a trusted partner for electronics manufacturers seeking efficient thermal solutions.

4. Ventec International Group Co., Ltd.

Headquarters: Taipei, Taiwan

Ventec International Group is a leading global supplier of advanced base materials for the PCB industry. The company specializes in high-performance IMS materials that offer exceptional thermal performance, reliability, and quality. Ventec’s tec-thermal range uses ceramic-filled halogen-free dielectric technology, serving automotive, medical, industrial, aerospace, and military sectors. With strong focus on innovation, Ventec develops solutions for heat dissipation in electronic modules and assemblies. Their products ensure high durability and consistent performance in demanding electronic environments. Ventec collaborates closely with clients to deliver technologically advanced IMS solutions tailored for high-performance thermal management applications worldwide.

5. Würth Elektronik eiSos GmbH & Co. KG

Headquarters: Waldenburg, Germany

Würth Elektronik eiSos is a prominent European manufacturer of electronic and electromechanical components. The company produces printed circuit boards and intelligent power and control systems, including IMS solutions that enhance heat dissipation and reliability in electronic assemblies. Würth Elektronik serves diverse industries, providing customized, high-performance solutions for automotive, industrial, and consumer electronics applications. With a strong presence in multiple countries, the company emphasizes quality, innovation, and efficient thermal management, supporting manufacturers in producing reliable and durable electronic products. Its IMS products are valued for performance, sustainability, and compatibility with advanced electronic systems.

Are you ready to discover more about the Insulated Metal Substrate market?

The report provides an in-depth analysis of the leading companies operating in the global Insulated Metal Substrate market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- NHK.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- AT&S

- Henkel

- Ventec

- WürthElektronik GmbH

- NCAB

- CML

- Denka

- ECM Group

- Guangdong CH Laminates Technology Corp Ltd.

Conclusion

The Global Insulated Metal Substrate (IMS) Market Size is poised for significant growth, driven by increasing demand for efficient thermal management solutions across electronics, automotive, and LED lighting industries. Rising adoption in high-density, miniaturized electronic circuits, power modules, and automotive applications underscores the critical role of IMS in enhancing performance, reliability, and energy efficiency. Trends such as eco-friendly materials, high-thermal conductivity substrates, and integration with advanced manufacturing and Industry 4.0 technologies further support market expansion. With innovation, sustainability, and performance at the forefront, IMS continues to emerge as an essential solution for modern electronics and industrial applications worldwide.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?