Top 25 Companies in Industrial Knitting Equipment Market in the World in 2025: Market Research Report (2024–2035)

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

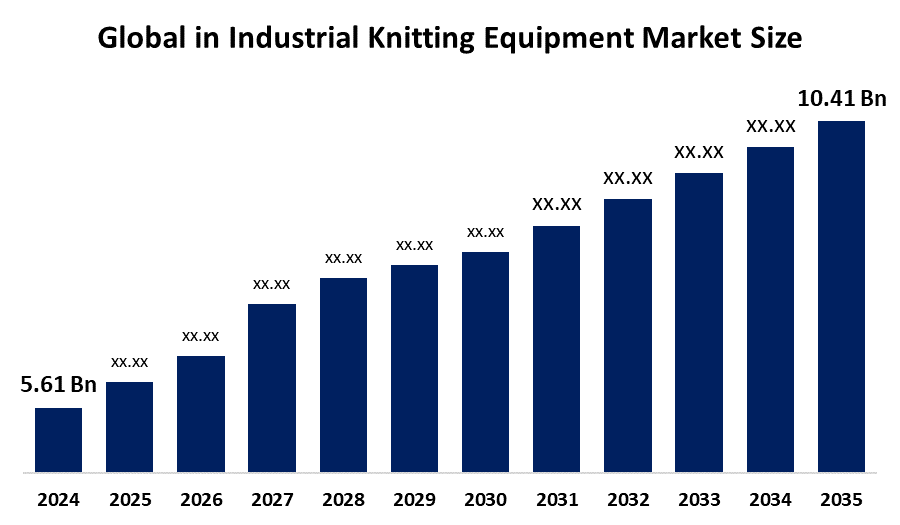

According to a research report published by Spherical Insights & Consulting, The Global Industrial Knitting Equipment Market Size is projected To Grow from USD 5.61 Billion in 2024 to USD 10.41 Billion by 2035, at a CAGR of 5.78 % during the forecast period 2025–2035. The industrial knitting equipment market offers future opportunities in automation, smart textiles, sustainable materials, customized apparel production, and integration with digital technologies, driven by rising demand in fashion, medical, and technical applications.

Introduction

The Industrial Knitting Equipment Market Size is evolving rapidly as industries embrace automation, sustainability, and advanced manufacturing technologies. These machines play a crucial role in producing textiles for fashion, sportswear, medical fabrics, automotive interiors, and technical applications. Modern knitting equipment integrates digital controls, computer-aided design, and energy-efficient features to enhance productivity and minimize waste. Growing consumer demand for customized and eco-friendly apparel is encouraging manufacturers to innovate with smart textiles and flexible production systems. Additionally, expanding applications in healthcare and industrial sectors are driving adoption, positioning industrial knitting equipment as a vital enabler of future textile industry growth.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Industrial Knitting Equipment market.

Industrial Knitting Equipment Market Size & Statistics

- The Market for Industrial Knitting Equipment Was Estimated to be Worth USD 5.61 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 5.78 % Between 2025 and 2035.

- The Global Industrial Knitting Equipment Market is Anticipated to Reach USD 10.41 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Industrial Knitting Equipment Market.

- Asia Pacific is expected to grow the fastest during the forecast period in the Industrial Knitting Equipment Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the Industrial Knitting Equipment market. The Asia-Pacific region features a vast number of textile manufacturing units, particularly in countries like China, India, and Bangladesh. Moreover, these countries are top exporters of knitted clothing and textiles, necessitating the use of advanced knitting machines to meet global demand.

North America is expected to generate the highest demand during the forecast period in the Industrial Knitting Equipment market. The increasing focus on sustainable and eco-friendly practices in the textile industry is driving the need for energy-efficient and green knitting technologies in the area. Additionally, the fashion and textile technology industry is significantly located in the United States, owing to the high demand for advanced knitting equipment in that region.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Industrial Knitting Equipment market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 5 Trends in Industrial Knitting Equipment Market

1. Automation & Smart Machinery

The adoption of automation and smart knitting machinery is transforming the textile industry by enhancing speed, precision, and cost-efficiency. Advanced knitting equipment now integrates robotics, sensors, artificial intelligence, and IoT-based systems, enabling real-time monitoring and predictive maintenance. These innovations reduce downtime, minimize errors, and optimize resource utilization. Manufacturers are also embracing computer-aided design (CAD) integration for seamless production of complex patterns with minimal manual intervention. This trend is driven by the growing demand for high-quality, large-scale textile production and the need to remain competitive in global markets by streamlining operations and improving overall productivity across the value chain.

2. Sustainable & Eco-Friendly Materials

Sustainability is a key driver in the industrial knitting equipment market, with increasing emphasis on reducing energy consumption, carbon emissions, and textile waste. Manufacturers are developing machines that support eco-friendly fibers, recycled yarns, and bio-based materials, aligning with global environmental regulations and consumer demand for greener products. Modern equipment emphasizes energy efficiency, lower water usage, and waste minimization. The shift to sustainable practices is not only reducing environmental impact but also opening opportunities for textile producers to differentiate themselves in competitive markets. This trend is shaping innovation in both machinery design and material integration for the textile industry’s future.

3. Customization & On-Demand Production

Rising consumer preference for personalized fashion is fueling demand for knitting equipment that supports customization and on-demand production. Advanced machines enable rapid prototyping, small-batch manufacturing, and flexible adjustments to meet unique customer requirements. With digital design integration, manufacturers can easily produce diverse patterns, textures, and sizes without compromising efficiency. This trend also aligns with the growing e-commerce and fast fashion sectors, where shorter lead times and quick responses to changing styles are critical. On-demand production reduces inventory costs, minimizes waste, and enhances profitability. Customization is becoming a central focus, driving equipment innovation for more agile, customer-centric textile production.

4. Growth of Smart Textiles

The increasing use of smart textiles is significantly influencing the industrial knitting equipment market. Smart fabrics, embedded with sensors, conductive yarns, or electronic components, are gaining popularity in healthcare, sportswear, defense, and wearable technology. Industrial knitting equipment is evolving to support production of these advanced fabrics with precise integration of functional fibers. These textiles monitor health conditions, track performance, or enhance safety, creating new business opportunities. Growing investment in research and development, coupled with rising consumer interest in wearable technology, is propelling this trend. Equipment manufacturers are focusing on compatibility with innovative fibers to capture the expanding smart textiles market.

5. Expansion in Technical Applications

Beyond fashion and apparel, industrial knitting equipment is increasingly being adopted in technical applications such as automotive interiors, aerospace components, industrial fabrics, and medical textiles. These sectors demand fabrics with high durability, flexibility, and performance under extreme conditions. Advanced knitting machines enable production of specialized fabrics with enhanced resistance to heat, chemicals, and wear. Growth in infrastructure, healthcare, and transportation industries is expanding the need for technical textiles globally. This trend highlights the diversification of applications for knitting equipment, as manufacturers invest in machines capable of producing innovative, high-performance textiles tailored to industrial and functional requirements.

Top 14 Companies Leading the Industrial Knitting Equipment Market

- Shima Seiki Mfg., Ltd.

- Stoll AG & Co. KG

- Mayer & Cie. GmbH & Co. KG

- Santoni S.p.A.

- Karl Terrot GmbH

- Orizio SRL

- Ningbo Cixing Co., Ltd.

- Jiangsu Yingyou Textile Machinery Co., Ltd.

- Tai Ho Shing Knitting Machinery Co., Ltd.

- Wellknit Machinery Co., Ltd.

- Yamato Sewing Machine Mfg. Co., Ltd.

- Jiangsu New Victor Industrial Co., Ltd.

- Zhejiang Taitan Co., Ltd.

- Others

1. Shima Seiki Mfg., Ltd.

Headquarters: Wakayama, Japan

Shima Seiki Mfg., Ltd. is a global leader in computerized flat knitting machines and textile design systems. Established in 1962, the company is best known for its pioneering WHOLEGARMENT® seamless knitting technology, which allows for waste-free production and enhanced efficiency. Its product portfolio includes CAD/CAM design systems, automated cutting machines, and advanced knitting solutions for apparel, industrial, and technical applications. With strong focus on sustainability, Shima Seiki integrates digitalization and eco-friendly processes across its operations. Headquartered in Wakayama, Japan, it serves clients worldwide through subsidiaries, sales offices, and service centers, consistently driving innovation in textile machinery.

2. Stoll AG & Co. KG

Headquarters: Reutlingen, Germany

Stoll AG & Co. KG, founded in 1873, is a historic name in flat knitting machinery and is now part of the Karl Mayer Group. The company is headquartered in Reutlingen, Germany, where it develops high-performance solutions for fashion, sportswear, technical textiles, and medical applications. Stoll’s reputation is built on precision, quality, and innovation, offering a broad product line of flat knitting machines supported by advanced software and services. Its global network ensures customer support across multiple continents, with additional subsidiaries and training centers. Stoll combines over a century of expertise with cutting-edge technology, bridging traditional textile craftsmanship and modern digitalization.

3. Mayer & Cie. GmbH & Co. KG

Headquarters: Albstadt, Germany

Mayer & Cie. GmbH & Co. KG is a family-owned German company specializing in circular knitting machines. Founded in 1905, it is headquartered in Albstadt, where its main R&D, administration, and production facilities are based. The company manufactures a wide range of machines for producing fabrics used in fashion, sportswear, underwear, technical textiles, and industrial applications. Mayer & Cie. is also active in braiding technology, expanding its market reach. With subsidiaries in Europe and Asia, the company emphasizes innovation, sustainability, and customer-oriented service. Its long-standing expertise makes it a trusted name in knitting technology worldwide, combining tradition with modern engineering.

4. Santoni S.p.A.

Headquarters: Brescia, Italy

Santoni S.p.A., founded in 1919, is an Italian manufacturer of circular knitting machines and the pioneer of “Seamlesswear” technology. Headquartered in Brescia, the company has revolutionized textile production by enabling seamless garments for fashion, sportswear, lingerie, and medical textiles. Santoni’s product portfolio emphasizes automation, digital solutions, and sustainability, supporting efficiency and material savings. As part of the Lonati Group, it benefits from strong synergies in textile machinery innovation and global distribution. With advanced R&D capabilities, Santoni continues to expand its influence in both apparel and technical textiles, delivering versatile solutions that meet modern industry demands while promoting eco-friendly practices.

5. Terrot GmbH

Headquarters: Chemnitz, Germany

Terrot GmbH, founded in 1862, is one of the world’s oldest and most respected manufacturers of circular knitting machines. Headquartered in Chemnitz, Germany, the company has a legacy of precision engineering and quality craftsmanship. Terrot’s machines are used across diverse markets including fashion, sportswear, technical textiles, and medical applications. Known for their durability and high performance, Terrot machines deliver efficiency and versatility to meet evolving market needs. Recently integrated into the Santoni Group, Terrot continues to strengthen its global footprint while preserving its German engineering tradition. With a focus on innovation and customer service, it remains a leader in textile machinery.

Are you ready to discover more about the Industrial Knitting Equipment market?

The report provides an in-depth analysis of the leading companies operating in the global Industrial Knitting Equipment market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Shima Seiki Mfg., Ltd.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- Stoll AG & Co. KG

- Mayer & Cie. GmbH & Co. KG

- Santoni S.p.A.

- Karl Terrot GmbH

- Orizio SRL

- Ningbo Cixing Co., Ltd.

- Jiangsu Yingyou Textile Machinery Co., Ltd.

- Tai Ho Shing Knitting Machinery Co., Ltd.

- Wellknit Machinery Co., Ltd.

Conclusion

The Industrial Knitting Equipment Market Size is entering a transformative era, driven by automation, digitalization, and sustainable practices. Growing adoption of smart machinery, eco-friendly materials, and on-demand production is reshaping how textiles are manufactured, supporting both mass production and customization. Applications are expanding beyond fashion into healthcare, automotive, and technical textiles, highlighting the sector’s versatility. With Asia Pacific leading production capacity and North America driving advanced technology demand, global competition is intensifying. Key industry players are investing in innovation, strategic partnerships, and eco-efficient solutions to stay ahead, ensuring steady growth and positioning knitting equipment as a cornerstone of future textiles.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?