Top 25 Companies in Aerospace Titanium Market in the World in 2025: Market Research Report (2024–2035).

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

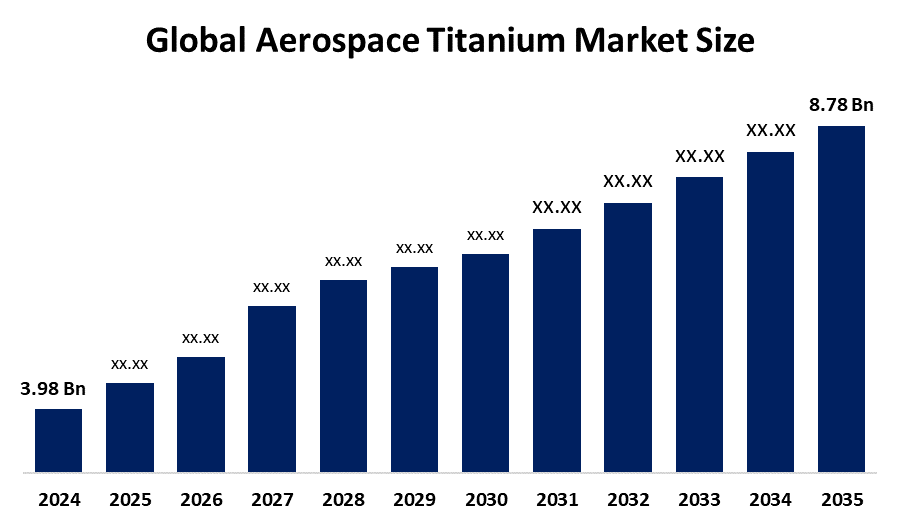

According to a research report published by Spherical Insights & Consulting, The Global Aerospace Titanium Market Size is projected to grow from USD 3.98 Billion in 2024 to USD 8.78 Billion by 2035, at a CAGR of 7.46 % during the forecast period 2025–2035. The Aerospace Titanium market offers opportunities through rising demand for lightweight, high-strength alloys, fuel-efficient aircraft, additive manufacturing, advanced coatings, aerospace expansion, and growing adoption in defense, commercial aviation, and space exploration sectors.

Introduction

The Aerospace Titanium Market Size is experiencing robust growth driven by increasing demand for high-performance, lightweight materials in the aviation and aerospace sectors. Titanium alloys are valued for their exceptional strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures, making them ideal for aircraft components, engines, airframes, and spacecraft. Rising emphasis on fuel efficiency, emission reduction, and durability in commercial and military aviation is accelerating titanium adoption. Technological advancements in alloy development, machining, and additive manufacturing further expand applications. As global aerospace production grows and space exploration initiatives advance, the titanium market is poised for significant expansion and innovation.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Aerospace Titanium market.

Aerospace Titanium Market Size & Statistics

- The Market Size for Aerospace Titanium Was Estimated to be Worth USD 3.98 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 7.46 % Between 2025 and 2035.

- The Global Aerospace Titanium Market Size is Anticipated to Reach USD 8.78 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Aerospace Titanium market.

- Asia Pacific is expected to grow the fastest during the forecast period in the Aerospace Titanium market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the Aerospace Titanium market. Asia Pacific is expected to grow fastest due to rapid expansion of commercial and defense aviation, increasing aerospace manufacturing investments, rising demand for lightweight, fuel-efficient materials, government support for aviation infrastructure, and the presence of key titanium suppliers and fabricators.

North America is expected to generate the highest demand during the forecast period in the Aerospace Titanium market. North America is expected to generate the highest demand due to a well-established aerospace industry, high commercial and defense aircraft production, advanced manufacturing technologies, substantial R&D investments, and strong adoption of lightweight, high-performance materials like titanium in aviation applications.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Aerospace Titanium market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 5 Trends in Aerospace Titanium Market

1. Growing Adoption in Commercial Aircraft Manufacturing

Aerospace titanium is increasingly used in commercial aircraft due to its high strength-to-weight ratio, corrosion resistance, and durability. Airlines and manufacturers are incorporating titanium in airframes, engine components, landing gear, and fasteners to reduce overall aircraft weight, improve fuel efficiency, and extend service life. Rising demand for next-generation, fuel-efficient, and environmentally friendly aircraft is further accelerating titanium adoption. Advanced fabrication techniques, including additive manufacturing and precision casting, enable complex titanium components, reducing production costs and lead times while meeting stringent safety and performance requirements across the aviation sector.

2. Expansion in Defense and Military Applications

Titanium’s exceptional strength, light weight, and corrosion resistance make it ideal for defense applications, including fighter jets, helicopters, missiles, and naval vessels. The increasing modernization of military fleets globally drives the demand for titanium components that enhance performance, survivability, and structural integrity. Governments are investing heavily in advanced aerospace programs, prioritizing materials that reduce weight while maintaining strength under extreme conditions. Innovations in titanium alloys and fabrication technologies enable customized solutions for defense applications. Rising geopolitical tensions and the need for technologically superior military aircraft further strengthen aerospace titanium demand in strategic regions worldwide.

3. Advancements in Additive Manufacturing and 3D Printing

Additive manufacturing is revolutionizing aerospace titanium production, allowing manufacturers to create complex, lightweight components with reduced material waste. 3D printing of titanium alloys enables precision-engineered parts for engines, structural components, and critical assemblies, improving performance and reducing assembly time. This trend supports rapid prototyping, shorter production cycles, and cost-effective manufacturing for small and large-scale aerospace projects. Innovations in powder metallurgy, laser sintering, and hybrid manufacturing processes enhance the mechanical properties and surface finish of titanium components. Adoption of additive technologies also enables weight optimization and fuel efficiency, aligning with sustainability goals and regulatory compliance in aerospace manufacturing.

4. Increasing Focus on Sustainable and Lightweight Aircraft

With fuel efficiency and carbon emissions reduction becoming critical, aerospace manufacturers are prioritizing lightweight materials like titanium. Titanium components replace heavier steel or aluminum parts, reducing overall aircraft weight, enhancing fuel economy, and lowering emissions. Environmental regulations and rising airline operational costs drive the demand for high-performance, sustainable materials. Manufacturers are exploring advanced titanium alloys that maintain strength while enabling weight reduction in wings, fuselage, and engine components. Lightweight, durable, and corrosion-resistant titanium also extends aircraft lifespan, reduces maintenance costs, and supports green aviation initiatives, aligning with global sustainability and energy-efficiency trends in aerospace design and production.

5. Development of Advanced Titanium Alloys

The aerospace industry is witnessing significant R&D in high-performance titanium alloys with enhanced mechanical properties, corrosion resistance, and fatigue strength. These advanced alloys enable engineers to design aircraft components capable of withstanding extreme temperatures, pressures, and operational stresses. Customization of titanium alloy composition allows improved manufacturability, surface finish, and weldability, critical for next-generation engines and airframes. Innovations such as near-alpha, beta, and titanium-aluminum-vanadium alloys are increasingly adopted to optimize structural performance while reducing weight. Continuous alloy development supports aerospace manufacturers in meeting stricter safety, durability, and performance standards, driving titanium adoption across commercial, defense, and space applications.

Top 16 Companies Leading the Aerospace Titanium Market

- Precision Castparts Corp

- Supra Alloys

- RTI International Metals

- VSMPO-AVISMA Corporation

- TIMET

- NIPPON STEEL CORPORATION

- Smiths Advanced Metals

- Kobe Steel, Ltd

- ATI Metals LLC

- Bralco Metals

- Acnis International

- Gould Alloys

- Weldaloy Specialty Forgings Company

- Plymouth Tube Company USA

- RELIANCE STEEL & ALUMINUM CO.

- Others

1. Precision Castparts Corp

Headquarters: Portland, Oregon, USA

Precision Castparts Corp (PCC) is a leading manufacturer of complex metal components, including aerospace-grade titanium products. The company specializes in investment casting, forging, and machining to produce high-performance components for commercial and military aircraft engines, airframes, and structural assemblies. PCC focuses on precision, reliability, and quality, serving major aerospace OEMs globally. With a strong emphasis on R&D, PCC develops advanced titanium alloys and manufacturing processes that optimize strength-to-weight ratios. Its extensive production capabilities and technical expertise make it a trusted supplier of critical aerospace titanium components worldwide.

2. Supra Alloys

Headquarters: New York, USA

Supra Alloys is a prominent aerospace supplier specializing in titanium and nickel-based alloys for high-performance applications. The company provides precision-engineered materials and components for commercial aircraft, defense systems, and space programs. Supra Alloys emphasizes material innovation, quality control, and technical support to meet stringent aerospace standards. Its titanium products include bars, sheets, plates, and forgings, designed to enhance durability, corrosion resistance, and weight efficiency. By investing in advanced metallurgy and fabrication technologies, Supra Alloys supports OEMs and MRO providers in achieving superior performance, reliability, and compliance with global aerospace specifications.

3. RTI International Metals

Headquarters: Pittsburgh, Pennsylvania, USA

RTI International Metals is a global leader in titanium mill products, fabricated components, and specialty alloys for aerospace applications. The company produces titanium sheets, bars, forgings, and structural parts for commercial, military, and space programs. RTI focuses on quality, precision, and innovation, delivering materials with high strength-to-weight ratios and excellent corrosion resistance. Its R&D initiatives enhance manufacturing processes, alloy composition, and fabrication techniques to support next-generation aerospace requirements. With a global distribution network and strong partnerships with OEMs, RTI International Metals plays a critical role in supplying reliable and high-performance titanium solutions to the aerospace industry worldwide.

4. VSMPO-AVISMA Corporation

Headquarters: Verkhnyaya Salda, Russia

VSMPO-AVISMA Corporation is the world’s largest titanium producer, supplying high-quality titanium and alloys to aerospace, defense, and industrial markets. The company specializes in titanium ingots, sheets, forgings, and precision components for commercial aircraft, military jets, and space applications. VSMPO-AVISMA emphasizes material innovation, stringent quality standards, and technological advancements to meet global aerospace requirements. Its integrated production process, from titanium sponge to finished products, ensures consistency, reliability, and scalability. Partnering with leading OEMs such as Boeing and Airbus, the corporation supports critical aerospace programs with advanced titanium solutions that enhance performance, reduce weight, and ensure durability under extreme conditions.

5. TIMET

Headquarters: Pittsburgh, Pennsylvania, USA

TIMET (Titanium Metals Corporation) is a premier manufacturer of titanium mill products for aerospace, defense, and industrial applications. The company supplies titanium sheets, plates, bars, and forgings used in commercial aircraft, military programs, and space systems. TIMET focuses on innovation, quality, and material performance, delivering alloys with superior strength, corrosion resistance, and fatigue properties. Through advanced production techniques and R&D, TIMET optimizes titanium products for high-performance aerospace applications. Its global presence and strong partnerships with leading OEMs enable reliable supply and support for critical projects, making TIMET a key player in the aerospace titanium market.

Are you ready to discover more about the Aerospace Titanium market?

The report provides an in-depth analysis of the leading companies operating in the global Aerospace Titanium market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Precision Castparts Corp.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- Supra Alloys

- RTI International Metals

- VSMPO-AVISMA Corporation

- TIMET

- NIPPON STEEL CORPORATION

- Smiths Advanced Metals

- Kobe Steel, Ltd

- ATI Metals LLC

- Bralco Metals.

Conclusion

The Aerospace Titanium market is poised for substantial growth as demand for lightweight, high-strength, and corrosion-resistant materials continues to rise across commercial, defense, and space sectors. Technological advancements in additive manufacturing, alloy development, and fabrication processes are expanding applications and improving efficiency. Increasing focus on fuel efficiency, sustainability, and performance optimization is driving titanium adoption in aircraft components, engines, and structural assemblies. With a growing number of aerospace programs, supportive government initiatives, and innovation in advanced alloys, the market presents significant opportunities for manufacturers and suppliers to enhance capabilities, meet evolving industry standards, and achieve long-term strategic growth.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?