Top 20 Companies in Global Inoculants For Iron Foundries Market (2025–2035): Spherical Insights Analysis

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

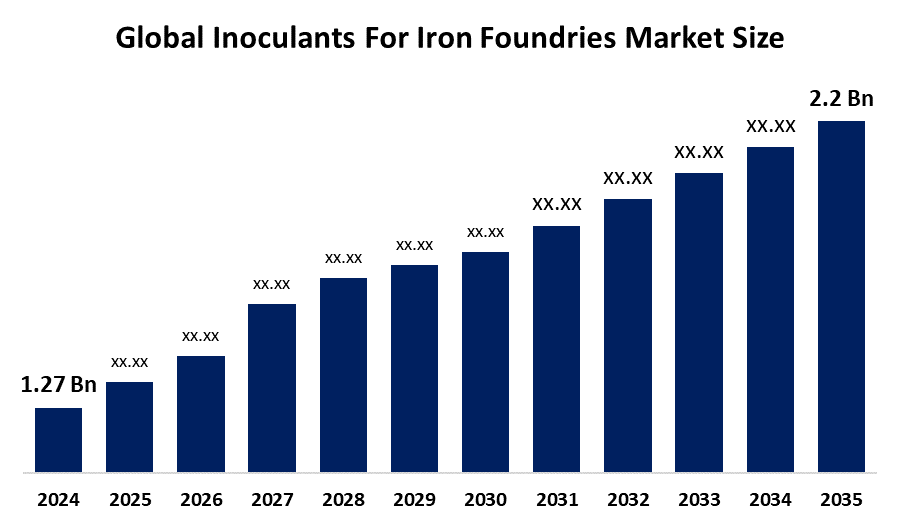

According to a research report published by Spherical Insights & Consulting, The Global Inoculants For Iron Foundries Market Size is projected To Grow from USD 1.27 Billion in 2024 to USD 2.2 Billion by 2035, at a CAGR of 5.12% during the forecast period 2025–2035. The inoculants for iron foundries market expand as demand rises for premium cast iron in automotive, construction, and industrial applications due to light weighting, infrastructure growth, and technological progress in casting technologies.

Introduction

The Inoculants For Iron Foundries Market Size refer to the business catering to materials injected into molten iron to improve its quality by optimizing grain structure and mechanical properties such as strength, ductility, and wear resistance. Inoculants are applied extensively in cast iron manufacturing in the automotive, construction, machinery, and pipe manufacturing industries to attain high casting performance and minimize defects. Market growth is characterized by increasing demand for prime castings of iron in automotive light weighting, infrastructure construction, and industrial machinery. Strengths include improved metallurgical properties, cost savings, and suitability to adapt cast iron properties to a given application. Opportunities are growing with the growing use of ductile iron and compacted graphite iron, which call for specialty inoculants to achieve the best performance. Future use of Agricultural Inoculants is expected to increase as farmers seek environmentally friendly and sustainable alternatives to conventional farming methods. Government programs for manufacturing modernization, environmental protection, encouraging cleaner production, and investments in sophisticated foundry technologies also drive market expansion. Public policies fostering sustainable metal casting processes and R&D on green technology in inoculant formulations also help in the positive outlook of the industry worldwide.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Inoculants For Iron Foundries Market.

Inoculants For Iron Foundries Market Size & Statistics

- The Market Size for Inoculants For Iron Foundries Was Estimated to be worth USD 1.27 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 5.12% between 2025 and 2035.

- The Global Inoculants For Iron Foundries Market Size is anticipated to reach USD 2.2 Billion by 2035.

- Asia Pacific is expected to generate the largest demand during the forecast period in the Inoculants For Iron Foundries Market

- North America is expected to grow the fastest during the forecast period in the Inoculants For Iron Foundries Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the inoculants for iron foundries market. North America is the rapidly growing inoculants market, fueled by increased demand for light, strong car parts, new foundry technologies, and massive investments in infrastructure. Strict environmental laws also encourage the use of premium inoculants, facilitating environmentally friendly manufacturing practices.

Asia Pacific is expected to generate the largest demand during the forecast period in the inoculants for iron foundries market. Asia Pacific is leading the inoculants for iron foundries market owing to increased industrialization and urbanization. Increased automotive, construction, and machinery industries in India and China increase the demand for superior quality castings. High numbers of foundries, with inexpensive labor and raw materials, also spur the market in the region.

Top 10 trends in the Inoculants For Iron Foundries Market

- Advanced manufacturing technologies

- Increasing demand for ductile iron

- Sustainability and green initiatives

- Innovative Formulations

- Focus on lightweight castings

- Customization and specialization

- Focus on quality control

- Automation and digitalization in foundries

- Advanced metallurgical properties

- Rising industrialization in emerging markets

1. Advanced manufacturing technologies

Advanced manufacturing technology increases inoculant application in foundries through real-time control of processes and accurate addition of materials, resulting in better quality cast iron, fewer defects, and greater efficiency with automation and smart systems.

2. Increasing demand for ductile iron

Growing demand for ductile iron, owing to its high strength and cost savings, calls for sophisticated inoculants to develop the desired spheroidal graphite structure. Inoculants offer nucleation sites for the stable development of graphite, improving the mechanical properties such as ductility and impact resistance, important in automotive usage.

3. Sustainability and green initiatives

Sustainability trends in iron foundry inoculants include applying sustainable inoculant material with environmentally friendly characteristics to minimize energy, waste, carbon footprints, and resource usage. These actions result in efficient and circular production, ensuring long-term economic sustainability and environmental stewardship in the iron casting sector.

4. Innovative Formulations

Emerging trends in inoculant formulation involve nanotechnology, eco-friendly, low-carbon chemistry, and Internet of Things integration to achieve higher casting quality at lower environmental costs, which are congruent with ESG objectives and provide IoT-based monitoring for accuracy control. The drivers come in the form of regulatory pressures to adopt greener technologies and rising demand from industrial production growth and additive manufacturing use cases.

5. Focus on lightweight castings

Lightweight iron casting is designed to save weight on the vehicle for improved fuel economy, with the help of thin thin-walled design and effective inoculants to manage graphite growth and maintain consistent properties. Inoculants create a beneficial state of nucleation, encouraging the formation of small graphite structures and preventing hardness scatter, which is critical to sustaining the structural integrity and performance of these lighter, thinner components.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the inoculants for iron foundries market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 12 Companies Leading the Inoculants For Iron Foundries Market

- Elkem ASA

- Ferroglobe PLC

- ASK Chemicals Metallurgy

- SinterCast AB

- Imerys S.A.

- Chemtura Corporation

- Henglilai

- Om Holdings Ltd.

- Kurtz Ersa Corporation

- Wescast Industries Inc.

- Benton Foundry Inc.

- Carbo Ceramics Inc.

1. Elkem ASA

Headquarters: Oslo, Norway

Elkem ASA is a silicon-based advanced materials global leader. Elkem has a key role in the inoculants for iron foundries market by supplying a full line of effective inoculants, including its highly valued Superseed series. These are specifically created to improve the nucleation process in cast iron, with graphite structure promotion, and to strengthen the mechanical properties of the castings. Elkem's inoculants find broad applications in the manufacture of ductile and gray iron castings, especially in the automotive and heavy machinery sectors. It reflects the company's focus on innovation and sustainability in its research and development of specialized inoculants that minimize defects in casting, e.g., chill and porosity, improving the quality and overall efficiency of the casting process.

2. Ferroglobe PLC

Headquarters: London, UK

Ferroglobe PLC is one of the largest producers of silicon and ferroalloys in the world. In the market for inoculants in iron foundries, Ferroglobe is dedicated to manufacturing premium ferrosilicon-based inoculants and nodularizers, including FeSiMg alloys, which are critical in developing the mechanical properties of cast iron. They are utilized to advance the spheroidal graphite formation in ductile iron castings and reduce the defects, thereby strengthening, making it more ductile, and enhancing its impact resistance. Ferroglobe inoculants find extensive applications in automotive parts and industrial equipment. The company has several production plants around the world, making available the necessary critical materials to foundries across the world.

3. ASK Chemicals Metallurgy

Headquarters: Unterneukirchen, Germany

ASK Chemicals Metallurgy GmbH is a firm that specializes in the production and formulation of sophisticated inoculants for iron foundries. Mold inoculants such as Germalloy, SMW Inserts, and Optigran make up their product portfolio, which has the effect of improving mechanical properties like strength and toughness by increasing the graphite structure in cast iron. ASK Chemicals Metallurgy's innovations, including cerium and bismuth-based SMW Insert, provide benefits such as avoiding chunky graphite as well as reducing oxide and sulfide formations during casting. These developments lead to the manufacture of premium castings with improved uniformity and performance.

4. SinterCast AB

Headquarters: Stockholm, Sweden

SinterCast AB, a leader in process control technology for the manufacturing of Compacted Graphite Iron (CGI), is a global company. The firm is a specialist in offering precision measurement and control systems that allow foundries to cast premium CGI castings with repeatable microstructures. SinterCast technology features the System 4000, which automates the introduction of inoculants and magnesium into the molten iron to provide the best solidification behavior. Their solutions find extensive applications across the automotive sector for the production of engine components, leading to lighter, more fuel-efficient vehicles.

5. Imerys S.A.

Headquarters: Paris, France

Imerys S.A. is a worldwide specialist in mineral-based specialty solutions for several markets, among which is the foundry industry. With its business unit, Imerys Metal Casting Solutions, the company distributes a complete portfolio of green molding sand additives, including bentonites and coal-based additives, used to improve the performance of iron casting sand molds and cores. Imerys' products are formulated to improve mold stability, lower emissions, and maximize casting quality, in support of the manufacture of premium automotive and industrial castings. With international presence and a drive towards innovation, Imerys remains a major force in the foundry business.

Are you ready to discover more about the inoculants for iron foundries market?

The report provides an in-depth analysis of the leading companies operating in the global inoculants for iron foundries market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Elkem ASA

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Ferroglobe PLC

- ASK Chemicals Metallurgy

- SinterCast AB

- Imerys S.A.

- Chemtura Corporation

- Henglilai

- Om Holdings Ltd.

- Kurtz Ersa Corporation

- Others.

Conclusion

The Inoculants For Iron Foundries Market Size is about the additives to molten iron for improving grain structure and mechanical properties, which are essential in automotive, construction, and machinery applications. Lightweight, high-quality castings and environmentally friendly production drive growth. Players such as Elkem, Ferroglobe, ASK Chemicals, SinterCast, and Imerys are major players that offer innovative inoculants and technology, enabling better casting quality, efficiency, and environmental regulation in the face of rising industrialization and government incentives across the globe.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?