Top 20 Companies in Aerospace Robotics Market In the World in 2025: Market Research Report (2024–2035)

RELEASE DATE: Aug 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

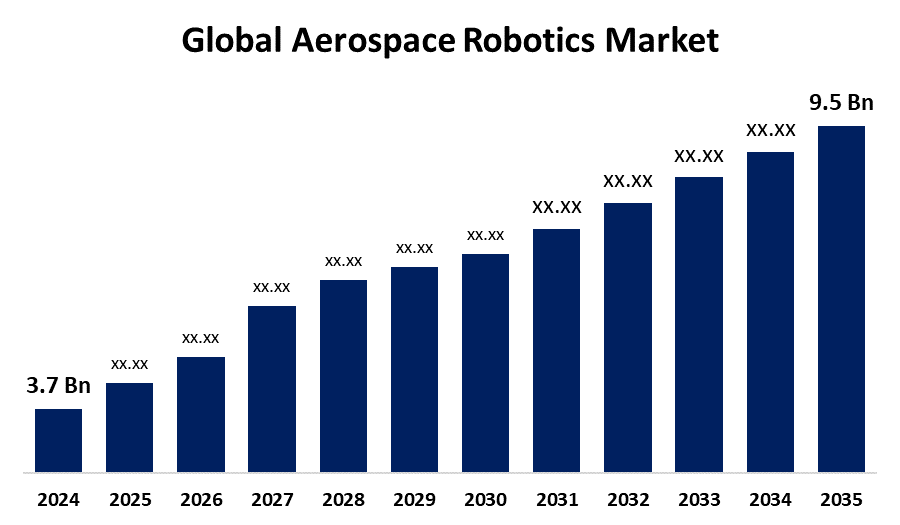

According to a research report published by Spherical Insights & Consulting, The Global Aerospace Robotics Market Size is projected to grow from USD 3.7 billion in 2024 to USD 9.5 billion by 2035, at a CAGR of 8.95% during the forecast period 2025–2035. The global market for aerospace robotics is expanding significantly due to developments in automation and robotics technologies used in the aerospace sector. In many aerospace applications, such as manufacturing, assembly, maintenance, and inspection duties, robotics is essential. Robotics adoption in aerospace lowers operating costs and cycle times while increasing productivity, accuracy, and safety. Unmanned aerial vehicles (UAVs), articulated robots, collaborative robots (cobots), and autonomous mobile robots (AMRs) are important robotic technologies used in aerospace. Each is designed to perform a particular task, such as welding, painting, drilling, or component handling.

Introduction

The Global Aerospace Robotics Market refers to the integration of robotic systems like articulated arms, self-driving cars, and drone-based platforms into aerospace production, maintenance, inspection, and space operations is referred to as the global aerospace robotics market. Throughout the aerospace value chain, including welding, painting, assembly, material handling, and non-destructive testing, these robotics technologies are intended to improve accuracy, decrease human error, and streamline workflows. Additionally, the main factors fostering a favorable market outlook is the notable expansion of the aerospace and aviation sectors worldwide. Further driving market expansion is the growing need to automate a number of labor-intensive inspections, fiber placement, sealing, and dispensing procedures. In keeping with this, the market is expanding due to the extensive manufacturing of narrow-body aircraft with lightweight and compact parts. The Internet of Things (IoT), artificial intelligence (AI), cloud computing solutions, and the combination of robotics and 3D visualization are some examples of technological developments that are contributing to growth. These technologies help to reduce turnaround time for manufacturing processes and enhance human-robot collaboration. It is expected that the market will grow due to additional factors, such as substantial advancements in the cyber-physical system (CPS) with automated decision-making capabilities and intensive research and development (R&D) activities.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Aerospace Robotics Market.

Aerospace Robotics Market Size & Statistics

- The Market Size for Aerospace Robotics was estimated to be worth USD 3.7 Billion in 2024.

- The Market Size is going to expand at a CAGR of 8.95% between 2025 and 2035.

- The Global Aerospace Robotics Market is anticipated to reach USD 9.5 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Aerospace Robotics Market.

- Asia Pacific is expected to grow the fastest during the forecast period in the Aerospace Robotics Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the aerospace robotics market. The market growth is driven by rapid industrialization, economic growth, and rising investments in aerospace infrastructure, Asia Pacific is becoming a key region in the global aerospace robotics market. As nations like China, Japan, and India develop their aerospace capabilities, there is an increasing need for robotics solutions that boost manufacturing productivity and aid in the production of both commercial and defense aircraft. The adoption of robotics throughout aerospace supply chains is fueled by the region's emphasis on technological advancement and economical manufacturing techniques, which helps to explain its increasing clout in the global aerospace market.

North America is expected to generate the highest demand during the forecast period in the aerospace robotics market. The market growth is driven by technological leadership and well-established aerospace manufacturing capabilities. Because of the region's thriving aerospace industry, which includes significant aircraft suppliers and manufacturers, there is a strong need for cutting-edge robotics solutions. Research and development (R&D) investments help to support the region's leadership in aerospace manufacturing efficiency and quality standards by fostering innovation in robotics technologies suited for aerospace applications.

Top 10 Aerospace Robotics Trends

- Adoption of Collaborative Robots (Cobots)

- AI and Machine Learning Integration

- Advanced Sensor Technologies

- Automation of Complex Tasks

- Use of Lightweight and Flexible Robotic Arms

- Growth of Unmanned Aerial Vehicles (UAVs)

- Smart Manufacturing Integration

- Rise in Space Robotics

- Remote Monitoring and Predictive Maintenance

- Focus on Safety and Regulatory Compliance

1. Adoption of Collaborative Robots (Cobots)

The aerospace industry is making a big move toward safer and more effective manufacturing and maintenance procedures with the use of collaborative robots, or cobots. In contrast to conventional industrial robots, cobots are designed to work side by side with humans without the need for safety cages, allowing for smooth communication between humans and machines. Cobots aid in repetitive or precise tasks like fastening, sealing, and component handling during aircraft assembly and maintenance, which lowers human error and fatigue while increasing productivity.

2. AI and Machine Learning Integration

The way robotic systems behave and react to challenging situations is being completely transformed by the incorporation of artificial intelligence (AI) and machine learning into aerospace robotics. These robots are capable of autonomous decision-making, conditional adaptation, and real-time action optimization by utilizing AI algorithms. By using data analysis and machine learning, systems can anticipate maintenance requirements before failures happen and increase operational efficiency, facilitating continuous improvement.

3. Advanced Sensor Technologies

The way robotic systems behave and react to challenging situations is being completely transformed by the incorporation of artificial intelligence (AI) and machine learning into aerospace robotics. These robots are capable of autonomous decision-making, conditional adaptation, and real-time action optimization by utilizing AI algorithms. By using data analysis and machine learning, systems can anticipate maintenance requirements before failures happen and increase operational efficiency, facilitating continuous improvement.

4. Automation of Complex Tasks

The aerospace industry has made great strides in automating complex tasks; today, robots can perform complex tasks like drilling, welding, painting, and sealing with remarkable accuracy and reliability. These once labor-intensive and human error-prone tasks are now performed by robotic systems that have multi-axis control, sophisticated sensors, and vision technologies. This lowers operating costs and speeds up production schedules while also guaranteeing consistent quality across aircraft components.

5. Use of Lightweight and Flexible Robotic Arms

In order to improve agility and efficiency in production and maintenance settings, aerospace manufacturers are increasingly using lightweight, flexible robotic arms. These cutting-edge systems, which are frequently constructed from high-strength alloys or composite materials, are made to be both resilient and nimble, enabling them to function in confined or intricate areas within aircraft structures. For tasks requiring a high degree of precision, their lighter weight allows for faster, more responsive movements and less strain on support systems.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the aerospace robotics market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Aerospace Robotics Market

- KUKA AG

- ABB Group

- FANUC Corporation

- Yaskawa Electric Corporation

- Kawasaki Heavy Industries Ltd.

- Mitsubishi Electric Corporation

- Electroimpact Inc.

- JH Robotics

- Comau S.p.A

- Staubli International AG

- Universal Robots

- Northrop Grumman Corporation

- Oliver Crispin Robotics Limited

- Seiko Epson Corporation

- Boston Dynamics

- Bosch Rexroth AG

- Others

1. KUKA AG

Headquarters – Augsburg, Germany

Automation company KUKA AG (KUKA) is a division of Midea Group Co Ltd. It offers sophisticated automation solutions for a range of general and industrial uses. Industrial robots, automated manufacturing systems with tools, system components, and automated manufacturing cells, assembly lines, and automobile engine and transmission assembly systems are just a few of the company's many products. KUKA provides its clients with engineering services as well. Among other industries, the company provides services to the automotive, retail, energy, electronics, metal, food and healthcare, and consumer goods sectors.

2. ABB Group

Headquarters – Zurich, Switzerland

Global technology corporation ABB Ltd. (ABB) is an expert in automation and electrification. The business provides a variety of goods and services, such as automation solutions, drives, motors, generators, and electrical products. With solutions for sectors like consumer electronics, automotive, and oil and gas, ABB is linked to well-known names in automation and electrification. Customers use its products in a variety of industries, such as utilities, buildings, transportation, and industry. To reach its clients, ABB uses a network of distribution networks and channel partners.

3. FANUC Corporation

Headquarters – Oshino, Yamanashi, Japan

FANUC Corporation is a world leader in factory automation, with a focus on industrial robotics, CNC systems, and ROBOMACHINE tools. Operating under the "one FANUC" philosophy, which prioritizes smooth integration and lifetime service support, the company is divided into three main business units: FA (Factory Automation), ROBOT, and ROBOMACHINE. The technologies developed by FANUC are extensively used in the manufacturing sector, allowing for accuracy, effectiveness, and scalability in automated production settings across the globe.

4. Yaskawa Electric Corporation

Headquarters – Kitakyushu, Fukuoka Prefecture, Japan

Yaskawa Electric Corp (Yaskawa Electric) is a multinational company that specializes in manufacturing electrical products for a range of industries. Development of products and technologies that support social infrastructure, such as those of steel plants, cement applications, and cutting-edge industries, is one of the company's primary activities. Servo motors, AC Drives/Inverters, and industrial robots all of which are renowned for their exceptional operating accuracy are among Yaskawa Electric's main products. A vast array of industries, including automotive, semiconductors, electronic components, next-generation telecommunications, food manufacturing, agriculture, and biomedical, use the company's products. Applications for Yaskawa's products in social infrastructure include pumps, photovoltaic generation, oil and gas, air conditioning, elevators, and logistics.

5. Kawasaki Heavy Industries Ltd.

Headquarters – Minato, Tokyo, Japan

The technology conglomerate Kawasaki Heavy Industries Ltd. (Kawasaki) operates in a number of different industries. It manufactures and markets a broad range of goods across numerous industries, including rolling stock, engines, motorcycles, aircraft, jet engines, general-purpose gas turbine generators, hydraulic systems and components, submarines, bulk carriers, LNG/LPG carriers, and more. Additionally, the business provides plant engineering services for a range of industrial facilities, such as cement plants, chemical plants, boiler facilities, environmental protection facilities like municipal waste treatment plants, tunneling equipment, and steel structures like LNG tanks. Customers in a variety of industries, including consumer markets, transportation, energy, and aerospace, use the company's products.

Are you ready to discover more about the aerospace robotics market?

The report provides an in-depth analysis of the leading companies operating in the global aerospace robotics market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- KUKA AG

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

2. SWOT Analysis

- ABB Group

- FANUC Corporation

- Yaskawa Electric Corporation

- Kawasaki Heavy Industries Ltd.

- Mitsubishi Electric Corporation

- Electroimpact Inc.

- JH Robotics

- Comau S.p.A

- Staubli International AG

- Universal Robots

- Northrop Grumman Corporation

- Oliver Crispin Robotics Limited

- Seiko Epson Corporation

- Boston Dynamics

- Bosch Rexroth AG

Conclusion

The market for aerospace robotics is changing dramatically due to increased automation requirements, technological advancements, and the expansion of aerospace manufacturing worldwide. In order to increase accuracy, decrease human error, and boost operational efficiency, robotics is being incorporated into manufacturing, inspection, and maintenance tasks more and more. With the help of robust industrial ecosystems and calculated investments, important regions like North America and Asia Pacific are leading in terms of demand and growth, respectively. The competitive landscape is changing due to emerging trends like smart manufacturing, AI integration, and collaborative robots. Robotics will continue to be essential to future developments in the aerospace industry as businesses strive for sustainability and digitalization.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?