Industry 4.0: A swift wave hits the core of Industrial Horizon

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

What do you mean by Industry 4.0?

Industry 4.0, or the fourth industrial revolution, encompasses the incorporation of digital technologies within manufacturing and industrial operations to establish intelligent, interconnected, and self-sufficient systems. The business includes a diverse range of technologies, applications, and services that facilitate this change. Industry 4.0 is bringing about a revolutionary timeframe for companies, significantly transforming the environment of product creation, development, and delivery.

How will Industry 4.0 change the overall framework in several industrial sectors?

Here, manufacturers are incorporating seamlessly advanced technologies such as the Internet of Things (IoT), cloud computing, analytics, artificial intelligence, and machine learning into their production sites and operational frameworks competitiveness. Further, key intelligent factories are equipped with advanced sensors, integrated software, and robots that gather and examine data, enabling better decision-making. Beyond that, the principles and technologies of Industry 4.0 can be applied universally across multiple industrial sectors, including both discrete and process manufacturing, and specifically for oil and gas, mining, and various other industrial sectors.

Lights up at current revenue and business valuation:

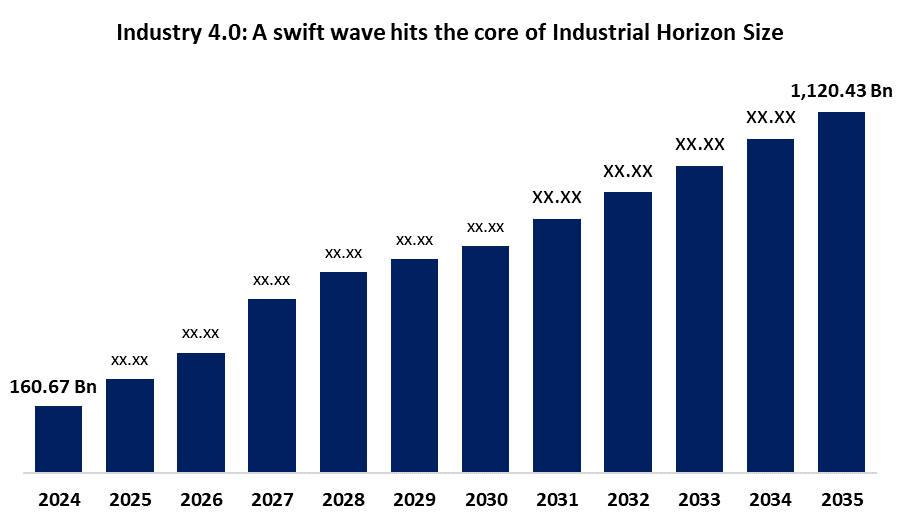

- The Market size for Industry 4.0 is about 160.67 Billion in 2024.

- The overall Market Size growth in 2025-2035, with a CAGR of 19.31%.

- At the end of 2035, the market value is estimated to be up to 1,120.43 Billion.

- The Asia Pacific continent holds the largest market share between the forecast period of 2025-2035.

- Besides, North America is anticipated to grow at the fastest CAGR between the forecast period of 2025-2035.

The market revenue growth with their co-partners: trends and barriers

Trends:

- Widespread Digitalisation and Factory Automation

- Artificial Intelligence (AI) and Machine Learning Integration

- Expansion of Smart Factories

- 5G Connectivity and Edge Computing Deployment

- Digital Twins Technology

- Human-Machine Collaboration

- Focus on Cybersecurity

- Sustainability and Energy Efficiency

- Rising Adoption in Emerging Markets

- Innovation Ecosystems and Funding Growth

- Artificial Intelligence (AI) and Machine Learning Integration

Analytics powered by AI and predictive models revolutionise manufacturing processes, quality assurance, and supply chain operations, improving decision-making and minimising waste.

- Expansion of Smart Factories

Completely autonomous, interconnected manufacturing units utilising cyber-physical systems, digital twins, and robotics are becoming standard, enhancing operational agility and flexibility.

- 5G Connectivity and Edge Computing Deployment

Ultra-rapid, low-delay communication networks like 5G facilitate smooth, instant data transfer between devices, improving automation and remote management functions.

- Human-Machine Collaboration

Improved engagement between employees and machines via augmented reality (AR), virtual reality (VR), and collaborative robots (cobots) increases efficiency and safety.

- Sustainability and Energy Efficiency

Industry 4.0 technologies promote energy conservation and lessen environmental effects through enhanced resource utilisation and process effectiveness.

Barriers:

Despite substantial growing opportunities and industrial evolution, the lack of a skilled workforce and talent for managing and leveraging these technologies is a limitation. Further, cybersecurity threats and data privacy challenges create obstacles to the industry 4.0 market expansion.

Snapshot of the regional growth for the industry 4.0 market.

Asia Pacific:

The Asia Pacific region is quickly becoming a worldwide centre for Industry 4.0, propelled by swift digital transformation in manufacturing and industrial sectors. Further, the key elements encompass rising utilisation of sophisticated technologies like the Internet of Things (IoT), artificial intelligence (AI), robotics, and big data analytics, with accelerated urban growth, government efforts supporting smart manufacturing, and increasing investments in Industry 4.0 infrastructure, are additionally driving market development. Moreover, the Asia Pacific to adopt Industry 4.0 solutions more rapidly, with the help of countries such as China, Japan, South Korea, and India, which have suitable infrastructure with financial efforts, and utilise it to enhance their industrial competitiveness globally in the Industry 4.0 wave.

Recent insights:

- SAMARTH Udyog Bharat 4.0 is an initiative of the Ministry of Heavy Industry & Public Enterprises, Government of India, focused on Industry 4.0 as part of its program aimed at boosting competitiveness in the Indian capital goods sector. SAMARTH Udyog includes manufacturers, suppliers, and clients as the primary stakeholders. Experiential and demonstration centres for Industry 4.0 have been suggested to raise awareness of I4.0 within Indian manufacturing sectors. Five I4.0 centres with distinct identities for promoting awareness and branding have been approved under SAMARTH Udyog. It is highlighted that these centres would facilitate resource sharing, a shared platform for Industry 4.0, and interconnect each other’s resources to optimise resource utilisation.

- The I-KOREA 4.0 program is the South Korean government's all-encompassing national plan to address the opportunities and challenges presented by the Fourth Industrial Revolution. The main goal of I-KOREA 4.0 is to develop an innovation-focused ecosystem by improving R&D capabilities, fostering public-private partnerships, and reforming regulatory structures to be more adaptable and responsive. The government revealed its initiative to establish a 50 trillion-won ($34.4 billion) fund aimed at aiding the semiconductor, rechargeable battery, bio, artificial intelligence (AI), and other advanced sectors to strengthen Korea's industrial competitiveness. The proposal was approved during a weekly gathering of economy-focused ministers, chaired by acting President Choi Sang-mok, as stated by the finance ministry.

Europe:

Europe is leading the industry 4.0 revolution, propelled by a blend of sophisticated manufacturing abilities, robust government backing, and a well-trained labour force. Main growth drivers comprise substantial funding in research and development, especially in nations such as Germany, France, and the Netherlands, where industrial innovation is prioritised. The European Union has also been vital in fostering digital transformation via initiatives like the Digital Europe Programme and Horizon Europe. Additionally, Europe's emphasis on sustainability and intelligent manufacturing is driving sectors to implement technologies such as AI, IoT, robotics, and data analytics to improve productivity and lessen environmental effects. Partnerships among research institutions, startups, and major companies drive innovation, establishing Europe as a competitive frontrunner in the global transition to Industry 4.0.

Recent insights:

- The European Industry 4.0 market had a valuation of $24.5 billion in 2020 and is expected to expand by 16.4% each year. This is due to enhanced operational efficiency and productivity, increased research and development investment, and notable progress in IoT, 3D printing sector, big data, 5G connectivity, immersive technologies such as AR and VR, and artificial intelligence.

- On 10 March 2020, the European Commission initiated a New Industrial Strategy for Europe, emphasising its broad goals for the 'twin transition,' a path towards achieving climate neutrality, and digital evolution. The EU Industrial Strategy identifies three key factors for industrial growth.

- Germany: Germany has positioned itself as the global centre for Industrie 4.0, with “Industrie 4.0” also being solidly established as a powerful global brand. “Industrie 4.0” (Industry 4.0 (I40)) represents a national strategic effort by the German government via the Ministry of Education and Research. (BMBF) sowie das Ministerium für Wirtschaft und Energie (BMWI). Its goal is to propel digital advanced manufacturing through enhanced digitisation and the integration of products and value chains, and commercial frameworks.

North America:

The supremacy of North America in the Industry 4.0 sector is due to its sophisticated industrial foundation, supportive environment for innovation, expansive market size, and prompt integration of advanced technologies like IoT, AI, and cloud computing. The region's well-established manufacturing and technology industries, strong startup culture, significant venture capital investment, and favourable regulatory landscape have encouraged the development of Industry 4.0 startups and enterprises. Moreover, companies in North America have been leaders in creating and marketing Industry 4.0 technologies, providing them a competitive advantage in the international market.

Recent Insights:

- In recent years, North American governments, particularly in the United States and Canada, have greatly enhanced support for Industry 4.0 via extensive funding, strategic laws, and incentive initiatives. In the United States, the CHIPS and Science Act (2022) allocate billions of dollars for semiconductor production, advanced research and development, workforce education, and tax incentives to enhance domestic capabilities. For instance, the U.S. Department of Energy has initiated grant programs totalling $750 million through the Advanced Energy Manufacturing and Recycling Grants to help small and medium manufacturers upgrade or construct advanced production facilities.

Major Companies play a vital role in this business.

- ABB Ltd

- Siemens AG

- Cognex Corporation

- Schneider Electric SE

- Honeywell International Inc.

- Emerson Electric Co.

- Rockwell Automation Inc.

- General Electric Company

- Robert Bosch GmbH

- Cisco Systems Inc.

- 3D Systems

- Advantech

- Basler

- Daifuku

- IBM

1. Siemens AG

HQ Office: Munich, Germany

Main Concentration: Industrial automation, digital twin, IIoT, artificial intelligence

Siemens is arguably the most significant entity in the industry 4.0 arena. Siemens delivers comprehensive solutions for smart factories via its Digital Industries unit—ranging from programmable logic controllers (PLCs) to industrial software such as NX, Teamcenter, and MindSphere, its open IIoT operating system. Key Offering: The Digital Enterprise Suite combines automation, edge computing, simulation, and AI, allowing businesses to develop and refine digital twins of complete production lines. For instance, Siemens’ Amberg facility in Germany serves as a model smart factory, with 75% of its production processes fully automated and managed through data analytics and AI.

2. ABB Ltd.

HQ Office: Zurich, Switzerland

Main Emphasis: Robotics, automation, electrification

ABB is a worldwide leader in robotics and process automation across various sectors, including automotive and food processing. The Ability platform of the company integrates connected devices, data, and AI to develop intelligent systems that adjust in real-time. Main Advantage: ABB’s cooperative robots (“cobots”) and AI-powered systems assist manufacturers in increasing productivity, enhancing safety, and minimising downtime. Prominent Project: ABB collaborated with BMW to automate and digitalise its manufacturing processes, greatly improving productivity and effectiveness.

3. General Electric Corporation (GE Digital)

HQ Office: Boston, Massachusetts, United States

Key Emphasis: Industrial analysis, IIoT, virtual replicas. Via its GE Digital segment, General Electric aims to integrate operational and information technologies. The Predix platform serves as an IIoT solution, facilitating data gathering, analysis, and application creation for intelligent manufacturing and energy systems. Key Strength: A strong history in industrial equipment provides GE with a distinct edge in merging industry knowledge with contemporary analytics. Case Study: GE employs its own digital twin technologies to track jet engine performance, lowering maintenance expenses and enhancing reliability throughout aviation fleets

4. Honeywell Global Inc.

HQ Office: Charlotte, North Carolina, USA

Main Emphasis: Automation technologies, cybersecurity, edge computing. Honeywell provides interconnected industrial solutions in industries such as aerospace, chemicals, and oil & gas. Its Forge platform combines operational technology (OT) and information technology (IT) to provide comprehensive visibility and control. Key Offering: Honeywell Forge delivers analytics-based insights into asset performance, energy consumption, and employee productivity.

Innovation: Honeywell is enhancing cybersecurity for industrial control systems (ICS)—an increasing focus as Industry 4.0 connectivity expands

5. Intel Corporation

HQ Office: Santa Clara, California, USA

Major Concentration: Semiconductors, edge artificial intelligence, and visual computing. Intel supplies the essential hardware that drives Industry 4.0, including high-performance processors, FPGAs, edge computing modules, and AI accelerators. Its chips are utilised in robotic systems, industrial computers, intelligent sensors, and vision-based quality inspection devices. Intel enables developers to create AI-driven computer vision applications for manufacturing automation using its OpenVINO toolkit. Collaborations: Intel collaborates with Siemens, ABB, and other industry leaders to create smart manufacturing frameworks utilising its advanced silicon technology.

Recent Handshakes for Industry 4.0!

1. In September 2025, Hitachi built a global AI Factory using Nvidia GPUs to deliver physical AI—industrial AI combined with domain-specific SLMs and LLMs for rail, energy, factories, and infrastructure. The initiative integrated IoT, digital twins, edge AI, and select private 5G capabilities. Hitachi also finalised a deal to acquire the German industrial AI consultancy Synvert, which was subsequently integrated into its US-based integrator business, GlobalLogic.

2. In April 2025, Hyundai formally launched Metaplant America (HMGMA) in Georgia—a $7.6 billion smart factory regarded as the most cutting-edge automotive manufacturing site in North America, driven by AI and private 5G. This facility establishes a new standard for Industry 4.0 in automotive production, integrating telecom-grade infrastructure with industrial automation.

Final Wrap Up:

Industry 4.0, also known as the Fourth Industrial Revolution, signifies the deep incorporation of digital technologies, including IoT, AI/Machine Learning, Cloud Computing, and Digital Twins, into manufacturing and industrial processes to develop smart, interconnected, and autonomous systems (Smart Factories). This transformative change is anticipated to elevate the market from $160.67 billion in 2024 to $1,120.43 billion by 2035, propelled by developments such as 5G connectivity, human-machine cooperation, and an emphasis on sustainability. Further, Asia Pacific and North America are promoting adoption through strategic government initiatives (SAMARTH Udyog in India, I-KOREA 4.0, CHIPS and Science Act in the US) and recent developments in the industry, like Hitachi's global AI Factory created with NVIDIA and Hyundai's AI-based Metaplant America, highlight the speeding progress of this industrial change.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?