Discover Top 50 Companies in Fused Magnesia: Global Share, Market Size, Revenue Report (2024-2035)

RELEASE DATE: Aug 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

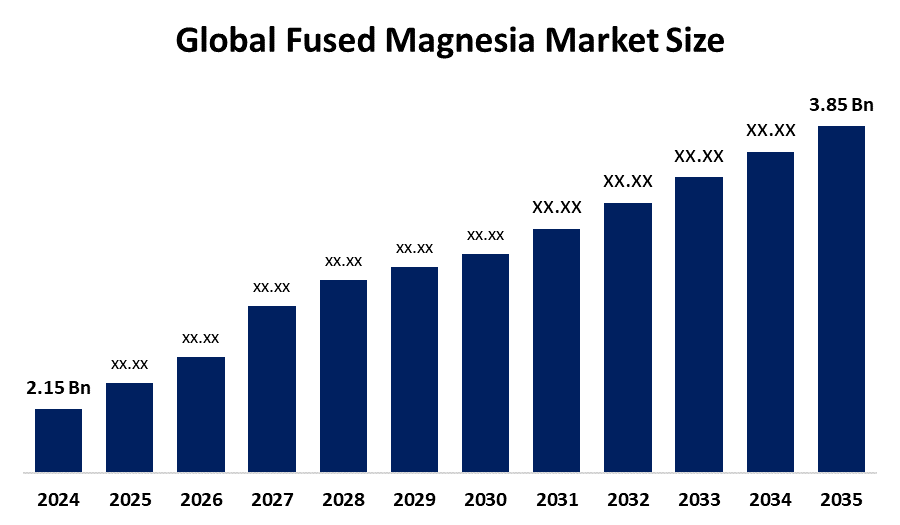

According to a research report published by Spherical Insights & Consulting, The Global Fused Magnesia Market Size is projected To Grow from USD 2.15 Billion in 2024 to USD 3.85 Billion by 2035, at a CAGR of 5.44% during the forecast period 2025-2035. The global fused magnesia market is being driven by the refractories sector's strong demand for fused magnesia as well as the traditional industries' increasing digital transformation.

Introduction

Fused magnesia refers to the manufacturing, marketing, and distribution of fused magnesia, a high-purity product of magnesium oxide (MgO) utilised in some electrical and high-temperature applications. Natural magnesite is melted in an electric arc furnace to create fused magnesia, also known as electrofused magnesia, a high-purity refractory material with a dense, highly crystalline structure. Fused magnesia is becoming more necessary due to the growing industrial activities, such as the steel, cement, and construction industries, as well as its essential function in high-temperature applications. Additionally, the need for fused magnesia in the metallurgical industry for sophisticated refractory materials is growing. Energy efficiency has increased due to technological developments in fusion kilns, increasing profitability and lowering carbon footprints. There are now more chances for businesses to create eco-friendly processes, such as employing renewable energy sources or putting recycling programs in place to produce fused magnesia, due to the increased emphasis on sustainability and eco-friendly products.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights-Download the Brochure now and dive deeper into the future of the Fused Magnesia Market.

Fused Magnesia Market Size & Statistics

- The Market Size for Fused Magnesia Was Estimated To be worth USD 2.15 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 5.44% between 2025 and 2035.

- The Global Fused Magnesia Market Size is anticipated to reach USD 3.85 Billion by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Fused Magnesia Market

- North America is expected to grow the fastest during the forecast period in the Fused Magnesia Market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the fused magnesia market. The significant expenditures in the steel, cement, and refractory industries, all of which depend more and more on high-purity fused magnesia for high-temperature and corrosion-resistant applications, North America is anticipated to grow the fused magnesia market at the highest rate. Growth is further accelerated by improvements in production technology, an increase in the need for long-lasting industrial materials, and government funding for manufacturing and infrastructure initiatives. Throughout the projected period, the region is well-positioned for strong market expansion due to its emphasis on innovation, quality, and efficiency.

Asia Pacific is expected to generate the highest demand during the forecast period in the fused magnesia market. With the fast industrialisation, urbanisation, and growing infrastructure projects in nations like China and India, the Asia Pacific region is anticipated to have the biggest demand for fused magnesium. Because fused magnesia is necessary for high-temperature applications and refractory linings, the region's expanding steel, cement, and refractory industries are the main drivers of consumption. Demand is further increased by growing investments in the manufacturing, energy, and construction industries. Asia Pacific is the fastest-growing and most profitable market throughout the projection period due to a combination of factors such as government measures to assist industrial growth, technical advancements, and expanding production capacity.

Top 10 trends in the Fused Magnesia Market

- Rising demand from the steel industry for high-purity refractory materials

- Increasing consumption in cement and construction applications

- Growth in chemical and metallurgical industries using fused magnesia

- Expansion of high-temperature industrial processes requiring corrosion-resistant linings

- Adoption of advanced manufacturing and automation technologies

- Development of eco-friendly and sustainable fused magnesia products

- Increasing investments in infrastructure and industrial projects

- Rising demand in the Asia Pacific and emerging markets

- Focus on improving material quality and thermal performance

- Integration of fused magnesia in innovative applications, including electronics and environmental technologies

1. Rising demand from the steel industry for high-purity refractory materials

Steel manufacture requires fused magnesia because it offers thermal stability and resistance to corrosion. The need for high-purity fused magnesia is driven by an increase in steel production, particularly in speciality and high-grade goods.

2. Increasing consumption in cement and construction applications

Fused magnesia is utilised in the cement and construction industries for high-temperature applications and refractory linings, which promote longevity and energy efficiency. Urbanisation and expanding infrastructural initiatives accelerate market expansion.

3. Growth in chemical and metallurgical industries using fused magnesia

The chemical inertness and high melting point of fused magnesia make it a popular material for metallurgical and chemical processing activities, allowing for long-lasting, safe, and effective industrial processes.

4. Adoption of advanced manufacturing and automation technologies

The quality, consistency, and scalability of fused magnesia are enhanced by modern production methods and automated systems, satisfying industrial efficiency and performance standards.

5. Expansion of high-temperature industrial processes requiring corrosion-resistant linings

The market demand is being driven by the growing reliance on fused magnesia linings for thermal resistance and durability in industries that use high-temperature processes, such as glass, ceramics, and power generation.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the fused magnesia market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 14 Companies Leading the Fused Magnesia Market

- RHI Magnesita

- Magnezit Group

- Liaoning Jinding Magnesite Group

- Haicheng Magnesite

- Kumas Manyezit Sanayi

- Imerys Fused Minerals

- Jiachen Group

- GRECIAN MAGNESITE

- Nedmag B.V.

- Premier Magnesia, LLC

- Others

1. RHI Magnesita

Headquarters: Vienna, Austria

RHI Magnesita is a world leader in the manufacturing and distribution of premium refractory products, such as fused magnesia, doloma, and speciality refractories. Long-lasting, heat-resistant, and chemically stable materials that improve equipment longevity and operating efficiency are supplied by the company. Innovative manufacturing technology, decades of industry experience, and cutting-edge research are all combined by RHI Magnesita to deliver high-performance, sustainable solutions. With scalable, dependable refractory systems that enhance safety, minimise downtime, and satisfy the increasing need for effective, energy-efficient, and ecologically friendly high-temperature solutions, the firm is trusted globally to support industrial operations.

2. Magnezit Group

Headquarters: Chelyabinsk, Russia

Magnezit Group is a top manufacturer of fused magnesia and refractory materials. The business specialises in high-purity, corrosion-resistant, thermally stable materials that extend the life of machinery and improve industrial efficiency. Magnezit Group provides dependable, scalable, and sustainable refractory solutions by fusing decades of experience with cutting-edge production technologies. Trusted in both Russian and foreign markets, it enhances operational safety, supports high-temperature operations, and satisfies the increasing industrial needs for long-lasting, ecologically friendly, and energy-efficient materials in high-performance applications such as building and steelmaking.

3. Liaoning Jinding Magnesite Group

Headquarters: Liaoning, China

Liaoning Jinding Magnesite Group serves the refractory, cement, and steel industries. High-purity, corrosion-resistant, and thermally stable materials are produced by the company to improve durability and efficiency in high-temperature operations. Liaoning Jinding provides dependable, scalable, and sustainable solutions by utilising cutting-edge production technologies and decades of experience. Reputable both domestically and abroad, the business fosters industrial expansion by offering high-performance, energy-efficient refractory materials that satisfy exacting quality requirements and the growing need for long-lasting, ecologically friendly goods in a variety of industrial sectors.

4. Haicheng Magnesite

Headquarters: Haicheng, China

Haicheng Magnesite is a prominent producer of fused magnesia and magnesite-based refractory products, serving the steel, cement, and industrial sectors. The company specializes in high-quality, thermally stable, and chemically resistant materials that enhance durability and operational efficiency. By combining advanced manufacturing techniques with extensive industry expertise, Haicheng Magnesite delivers reliable, scalable, and sustainable solutions. Trusted regionally and internationally, the company supports high-temperature industrial processes, improving performance, safety, and energy efficiency while meeting the growing global demand for high-performance and environmentally responsible refractory materials.

5. Kumas Manyezit Sanayi

Headquarters: Istanbul, Turkey

Kumas Manyezit Sanayi is a top Turkish producer of fused magnesia and refractory materials. The company manufactures corrosion-resistant, high-purity, thermally stable products that extend the life of equipment and improve process effectiveness. Utilising cutting-edge production methods and a wealth of industry knowledge, Kumas Manyezit provides dependable, scalable, and environmentally friendly solutions. The company, which is trusted both domestically and abroad, promotes industrial progress by offering high-performance, energy-efficient refractory materials that satisfy stringent quality standards and satisfy the growing need for long-lasting, ecologically friendly products in a variety of verticals.

Are you ready to discover more about the Fused Magnesia market?

The report provides an in-depth analysis of the leading companies operating in the global fused magnesia market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- RHI Magnesita

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

- Magnezit Group

- Liaoning Jinding Magnesite Group

- Haicheng Magnesite

- Kumas Manyezit Sanayi

- Imerys Fused MIstanbul, Turkeyinerals

- Jiachen Group

- GRECIAN MAGNESITE

- Nedmag B.V.

- Premier Magnesia, LLC

- Others

Conclusion

The increased demand for high-purity, thermally stable, and corrosion-resistant materials from the steel, cement, and refractory industries, the fused magnesium market is expanding quickly. Automation, IoT, and artificial intelligence (AI) are examples of technological developments that improve supply chain management, quality assurance, and production efficiency. Adoption is further supported by energy-efficient procedures and sustainability initiatives. Market opportunities are growing as a result of growing industrialization, the expansion of infrastructure, and new uses in chemicals, metallurgy, and construction. The market for fused magnesium is positioned for long-term industrial significance and steady global expansion thanks to innovation, scalable production, and an emphasis on performance and environmental compliance.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?