Discover Top 40 Companies in Circumfluent Cyclone Separator: Global Share, Market Size, Revenue Report (2024–2035)

RELEASE DATE: Oct 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

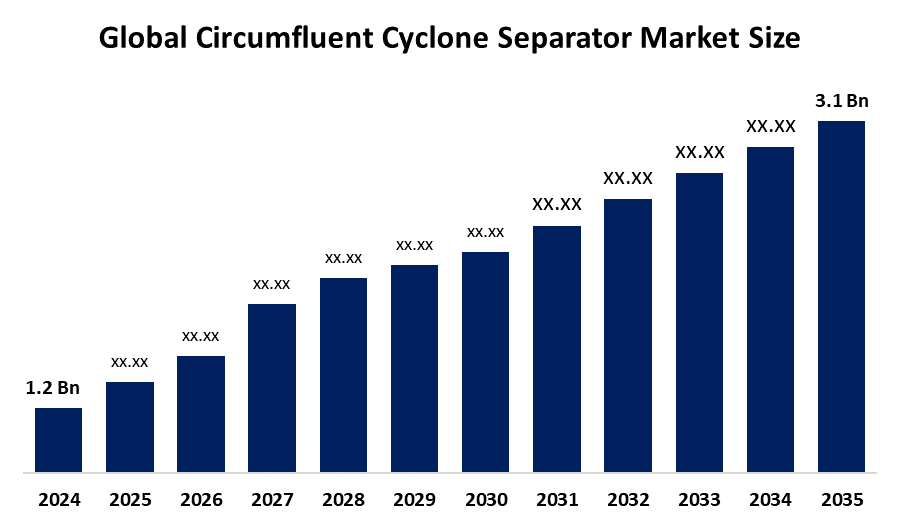

According to a research report published by Spherical Insights & Consulting, The Global Circumfluent Cyclone Separator Market Size is projected to Grow from USD 1.2 Billion in 2024 to USD 3.1 Billion by 2035, at a CAGR of 9.01% during the forecast period 2025–2035. The growing need for effective and affordable air and fluid separation technologies across a range of industries is the reason for this expansion.

Introduction

The global circumfluent cyclone separator market encompasses the development and utilization of innovative air pollution control equipment that utilizes centrifugal force to extract particulates from gas streams. Circumfluent cyclone separators have either a central or a spiral inlet that generates a swirling flow and increases the separation efficiency for fine particulates, distinguishing them from traditional designs. Additionally, there is an opportunity in the incorporation of digital technologies such as IoT and AI with cyclone separator systems. For example, IoT sensors and monitoring systems enhance tracking capabilities and make cyclone separation systems more effective by providing operator with real-time data to optimize performance. This provides operational efficiency, lowers maintenance costs, and otherwise improve the overall efficacy of the separation process. It is expected that smart and connected cyclone separator systems will open new avenues of growth.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Circumfluent Cyclone Separator Market.

Circumfluent Cyclone Separator Market Size & Statistics

- The Market Size for Circumfluent Cyclone Separator Was Estimated to be Worth USD 1.2 Billion in 2024.

- The Market Size is Going to Expand at a CAGR of 9.01% Between 2025 and 2035.

- The Global Circumfluent Cyclone Separator Market Size is Anticipated to Reach USD 3.1 Billion by 2035.

- North America is expected to generate the highest demand during the forecast period in the Circumfluent Cyclone Separator Market.

- Asia Pacific is expected to grow the fastest during the forecast period in the Circumfluent Cyclone Separator Market.

Regional growth and demand

Asia Pacific is expected to grow the fastest during the forecast period in the circumfluent cyclone separator market. Rapid urbanization and industrialization in places like China, India, and Southeast Asia are the main drivers of this growth. Demand for effective separation technologies is being driven by the region's growing industrial base and rising environmental consciousness. Cyclone separator use is also being fueled by government programs to reduce industrial pollution and enhance the quality of the air and water.

North America is expected to generate the highest demand during the forecast period in the circumfluent cyclone separator market. The use of high-efficiency separation solutions is required due to the stringent emissions regulations that the US and Canada have put in place to control industrial pollution. The market expansion in this area is also aided by the existence of a firmly established industrial sector and the ongoing emphasis on technological developments. Cyclone separator demand in North America is anticipated to continue to be high due to ongoing industrial modernization initiatives and regulatory pressures.

Top 10 Circumfluent Cyclone Separator Trends

1.More stringent environmental laws

2.Design Developments for Separators

3.Hybrid Separation Systems

4.Energy-Saving Functions

5.Increase in Applications at High Temperatures and High Dust

6.IoT Integration and Smart Monitoring

7.Tailoring to Specialty Sectors

8.Innovations in Materials for Durability

9.Development of Regional Infrastructure

10.Oil and Gas Sector Recovery

1.More stringent environmental laws

Industries are adopting high-efficiency separation technologies as a result of governments around the world imposing stricter emission standards. Because of their improved particulate removal capabilities, circulfluent cyclone separators are becoming more and more popular for compliance in industries like chemicals, cement, and electricity.

2.Design Developments for Separators

The geometry of separators is being revolutionized by computational fluid dynamics (CFD), which makes it possible to optimize internal flow paths and inlet structures. By lowering pressure drop and enhancing fine particle capture, these developments enhance performance in a variety of industrial settings.

3.Hybrid Separation Systems

To achieve superior multi-stage filtration, industries are combining bag filters or electrostatic precipitators with circumfluent cyclone separators. This hybrid strategy preserves operational flexibility while increasing the removal efficiency of ultrafine particles.

4.Energy-Saving Functions

Manufacturers are redesigning inlet and outlet configurations to minimize resistance in an effort to reduce energy consumption. To increase sustainability and reduce operating costs, new materials and low-friction coatings are also being investigated.

5.Increase in Applications at High Temperatures and High Dust

Circumfluent cyclone separators are becoming more popular in settings like steel, cement, and biomass plants where conventional filters don't work. They are perfect for harsh environments with high particulate loads because they can function without filter media.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the circumfluent cyclone separator market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 16 Companies Leading the Circumfluent Cyclone Separator Market

1.Alfa Laval AB

2.Donaldson Company, Inc.

3.GEA Group AG

4.Honeywell International Inc.

5.Nederman Holding AB

6.Parker Hannifin Corporation

7.Schenck Process Holding GmbH

8.Thermax Limited

9.Babcock & Wilcox Enterprises, Inc.

10.CECO Environmental Corp.

11.FLSmidth & Co. A/S

12.Hamworthy Combustion Engineering Ltd.

13.Hamon & Cie (International) S.A.

14.Hovmand A/S

15.Koch-Glitsch LP

16.Mitsubishi Hitachi Power Systems, Ltd.

1.Alfa Laval AB

Headquarters - Lund, Sweden.

Alfa Laval AB, also known as Alfa Laval, is a supplier of specialty goods and services for fluid handling, heat transfer, and separation. Centrifuges, pumps and valves, heat exchangers, boilers, decanters, burners, evaporation systems, high speed separators, and tank equipment are among its product offerings. Products from the company optimize processes like heating, cooling, separating, and transporting goods like water, oil, chemicals, beverages, and food. Energy, paper and pulp, steel, chemicals, food, dairy, and beverages, transportation, machinery, HVAC, mining, water and waste treatment, semiconductors, electronics, personal care, and pharmaceuticals are among the industries that the company serves.

2.Donaldson Company, Inc.

Headquarters - Minneapolis, Minnesota, the US.

Technology-led filtration products and solutions are developed and supplied by Donaldson Co. Inc. (Donaldson). Bulk fluid storage, compressed air and gas, engine and vehicle, gas turbine, hydraulics, industrial dust, fume and mist, membranes, and process filtration solutions are among its product offerings. The company works with clients ranging from small business owners to original equipment manufacturer (OEM) brands to address intricate filtration problems in a variety of markets and industries. Donaldson has production and distribution facilities on six continents.

3.GEA Group AG

Headquarters - Dusseldorf, Nordrhein-Westfalen, Germany.

The engineering group GEA Group AG (GEA) creates and produces process technologies and parts. The company's primary operations include manufacturing and distributing plants and machinery as well as offering cutting-edge components, process technology, and all-inclusive services. In addition to systems for brewing, liquid processing, filling & packaging, concentration, fermentation, crystallization, purification, drying, and powder handling, GEA's product line includes process engineering parts and equipment like separators, decanters, homogenizers, valves, and pumps.

4.Honeywell International Inc.

Headquarters - Charlotte, North Carolina, the US.

An integrated operating business, Honeywell International Inc. (Honeywell) provides services to numerous industries around the world. Through its many business divisions, the company focuses on offering solutions that improve comfort, safety, and productivity. The main goods and services offered by Honeywell are energy and sustainability solutions, building automation systems, industrial automation solutions, and aerospace technologies. Customers in sectors like building management, utilities, life sciences, aviation, and refining are served by the company's goods and services. In order to reach its customers, Honeywell uses a network of distribution networks and channel partners.

5.Nederman Holding AB

Headquarters - Helsingborg, Sweden.

Nederman Holding AB (Nederman) is a business that specializes in environmental technology. In order to address common issues with smoke, gas, dust, the workplace, material recycling, and efficient production, it focuses on developing and supplying air filtration and recycling products and solutions. The company sells a variety of goods, such as cyclone dust collectors, central vacuum systems, control equipment, bag house dust collectors, and cartridge dust collectors. Welding and thermal cutting, metalworking, composite machining, woodworking, vehicle services, fire and emergency stations, material handling and recycling, process industry, and energy are just a few of the industries that Nederman serves with its products and solutions.

Are you ready to discover more about the circumfluent cyclone separator market?

The report provides an in-depth analysis of the leading companies operating in the global circumfluent cyclone separator market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

1.Alfa Laval AB

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis

2.Donaldson Company, Inc.

3.GEA Group AG

4.Honeywell International Inc.

5.Nederman Holding AB

6.Parker Hannifin Corporation

7.Schenck Process Holding GmbH

8.Thermax Limited

9.Babcock & Wilcox Enterprises, Inc.

10.CECO Environmental Corp.

11.FLSmidth & Co. A/S

12.Hamworthy Combustion Engineering Ltd.

13.Hamon & Cie (International) S.A.

14.Hovmand A/S

15.Koch-Glitsch LP

16.Mitsubishi Hitachi Power Systems, Ltd.

Conclusion

The worldwide circumfluent cyclone separator market is changing quickly due to increasing environmental standards and modernization of industrial operations. Modern products featuring innovative design, energy efficiency, and smart monitoring are improving system performance and reliability. Regional growth is stimulated as infrastructure improves in Asia Pacific and regulations enforce change in North America. Adding in the benefits of the IoT and AI allow for new efficiencies. Hybrid systems and material advances broaden applications in various industries. The leading companies are looking to leverage these trends to improve market positioning while creating sustainable separation across numerous industries.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?