Discover Top 20 Companies in Maleic Anhydride Grafted SEBS: Global Share, Market Size, Revenue Report (2024-2035).

RELEASE DATE: Sep 2025 Author: Spherical InsightsRequest Free Sample Speak to Analyst

Description

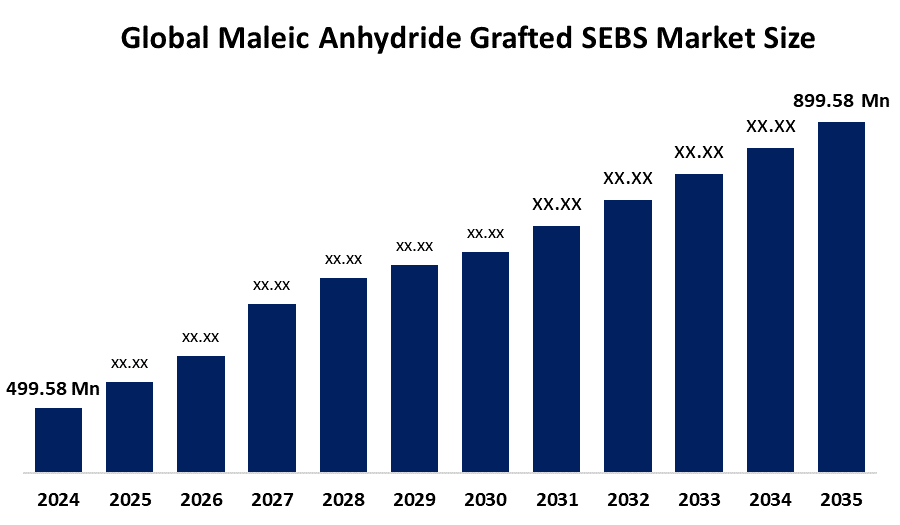

According to a research report published by Spherical Insights & Consulting, The Global Maleic Anhydride Grafted SEBS Market Size is projected to Grow from USD 499.58 Million in 2024 to USD 899.58 Million by 2035, at a CAGR of 5.49 % during the forecast period 2025–2035. The Maleic Anhydride Grafted SEBS market offers future opportunities through rising demand in automotive, construction, and packaging industries, driven by adhesion improvement, compatibility with polar polymers, and growth in sustainable, high-performance material applications.

Introduction

The Maleic Anhydride Grafted SEBS (Styrene-Ethylene-Butylene-Styrene) Market Size is gaining traction due to its superior properties such as enhanced adhesion, compatibility, flexibility, and durability. This modified elastomer is widely used in automotive, construction, packaging, electronics, and medical industries, where performance and reliability are critical. The grafting of maleic anhydride improves bonding with polar polymers and fillers, enabling its application in adhesives, sealants, impact modification, and coatings. Growing demand for lightweight, durable, and eco-friendly materials is driving adoption globally. With industries focusing on sustainable and high-performance solutions, Maleic Anhydride Grafted SEBS is poised to play a vital role in future applications.

Navigate Future Markets with Confidence: Insights from Spherical Insights LLP

The insights presented in this blog are derived from comprehensive market research conducted by Spherical Insights LLP, a trusted advisory partner to leading global enterprises. Backed by in-depth data analysis, expert forecasting, and industry-specific intelligence, our reports empower decision-makers to identify strategic growth opportunities in fast-evolving sectors. Clients seeking detailed market segmentation, competitive landscapes, regional outlooks, and future investment trends will find immense value in the full report. By leveraging our research, businesses can make informed decisions, gain a competitive edge, and stay ahead in the transition toward sustainable and profitable solutions.

Unlock exclusive market insights - Download the Brochure now and dive deeper into the future of the Maleic Anhydride Grafted SEBS market.

Maleic Anhydride Grafted SEBS Market Size & Statistics

- The Market Size for Maleic Anhydride Grafted SEBS Was Estimated to be Worth USD 499.58 Million in 2024.

- The Market Size is Going to Expand at a CAGR of 5.49 % Between 2025 and 2035.

- The Global Maleic Anhydride Grafted SEBS Market Size is Anticipated to Reach USD 899.58 Million by 2035.

- Asia Pacific is expected to generate the highest demand during the forecast period in the Maleic Anhydride Grafted SEBS market.

- North America is expected to grow the fastest during the forecast period in the Maleic Anhydride Grafted SEBS market.

Regional growth and demand

North America is expected to grow the fastest during the forecast period in the Maleic Anhydride Grafted SEBS market. Maleic Anhydride Grafted SEBS market, supported by advancements in automotive manufacturing, electronics, construction materials, and adoption of high-performance polymer solutions.

Asia Pacific is expected to generate the highest demand during the forecast period in the Maleic Anhydride Grafted SEBS market. Maleic Anhydride Grafted SEBS market, driven by rapid industrialization, strong automotive production, infrastructure development, and growing demand for advanced polymer materials.

Top 5 Trends in the Maleic Anhydride Grafted SEBS Market

1. Advancements in Polymer Chemistry

Ongoing research in polymer chemistry is driving innovation in Maleic Anhydride Grafted SEBS, enhancing its compatibility with other materials such as plastics, rubbers, and composites. These improvements result in better adhesion, flexibility, and mechanical performance, opening up new industrial applications. Companies are developing modified grades with enhanced thermal stability, chemical resistance, and processing capabilities to meet the needs of high-performance sectors like automotive, electronics, and consumer goods. Continuous innovation ensures that Maleic Anhydride Grafted SEBS remains adaptable for emerging applications, allowing manufacturers to create lightweight, durable, and versatile products that satisfy evolving industry demands globally.

2. Sustainability and Eco-Friendly Materials

Environmental concerns and regulatory pressures are pushing industries to adopt eco-friendly solutions, including bio-based or recycled variants of Maleic Anhydride Grafted SEBS. These materials reduce environmental impact while maintaining performance characteristics such as flexibility, impact resistance, and adhesion. Manufacturers are investing in green chemistry, sourcing sustainable feedstocks, and minimizing energy consumption during production. The push for circular economy practices encourages recycling and reuse of SEBS-based products in automotive, packaging, and electronics sectors. By combining sustainability with high performance, these materials help companies meet environmental standards and appeal to eco-conscious consumers, strengthening their position in a competitive global market.

3. Integration of Digital Technologies

Digital technologies like AI, IoT, and advanced monitoring systems are increasingly integrated into the production and application of Maleic Anhydride Grafted SEBS. Smart manufacturing solutions enable real-time quality control, precise material handling, and predictive maintenance, reducing waste and improving efficiency. Additionally, digital simulation tools allow engineers to model performance under various conditions, accelerating product development. These innovations enhance consistency, durability, and customization of SEBS-based components across industries. With data-driven insights, manufacturers can optimize processing parameters, ensure uniform product quality, and rapidly adapt to changing market requirements. Digitalization is transforming SEBS production into a smarter, more efficient, and competitive process.

4. Expansion in Automotive and Electronics Sectors

Maleic Anhydride Grafted SEBS is increasingly used in automotive and electronics industries due to its excellent flexibility, impact resistance, and adhesion. In vehicles, it serves in weather seals, gaskets, cable coatings, and vibration-damping components, improving performance and safety. In electronics, it enhances insulation, thermal stability, and mechanical protection for wiring and connectors. Rising demand for electric vehicles, smart devices, and miniaturized components is fueling SEBS adoption. Its ability to meet stringent performance standards, withstand harsh environments, and integrate with other materials makes it an indispensable solution. Consequently, these high-growth sectors are driving substantial market expansion for SEBS.

5. Growth in Emerging Markets

Emerging economies, particularly in Asia-Pacific, Latin America, and the Middle East, are driving significant demand for Maleic Anhydride Grafted SEBS. Rapid industrialization, infrastructure projects, automotive production, and consumer electronics manufacturing are increasing consumption. Manufacturers are targeting these markets with region-specific grades and solutions to meet local requirements. The combination of growing urbanization, rising disposable income, and government initiatives to boost manufacturing accelerates SEBS adoption. These regions also offer opportunities for cost-effective production, localized R&D, and strategic partnerships. As industrial and technological growth continues, emerging markets are becoming major contributors to the global SEBS market, supporting long-term expansion and innovation.

Empower your strategic planning:

Stay informed with the latest industry insights and market trends to identify new opportunities and drive growth in the Maleic Anhydride Grafted SEBS market. To explore more in-depth trends, insights, and forecasts, please refer to our detailed report.

Top 14 Companies Leading the Maleic Anhydride Grafted SEBS Market

- Kraton Corporation

- TSRC Corporation

- Asahi Kasei Corporation

- LCY Chemical Corp.

- China National Petroleum Corporation

- Mitsubishi Chemical Corporation

- DIC Corporation

- Dow Inc.

- Wanhua Chemical Group Co., Ltd.

- LG Chem Ltd.

- Sumitomo Chemical Co., Ltd.

- Kuraray Co., Ltd.

- Sinopec Shanghai Petrochemical Co., Ltd.

- JSR Corporation

1. Kraton Corporation

Headquarters: Houston, Texas, USA

Kraton Corporation is a global leader in styrenic block copolymers, including Maleic Anhydride Grafted SEBS. The company provides innovative elastomer solutions for automotive, construction, adhesives, and consumer products industries. Known for its high-performance materials, Kraton focuses on sustainability and energy-efficient solutions. Its R&D initiatives drive product customization and functional enhancements, enabling improved durability, flexibility, and processing performance. With a strong global presence, Kraton supports industrial and specialty markets through advanced polymer technologies and robust supply chains. Its commitment to innovation and environmental responsibility positions it as a leading supplier in the elastomer market.

2. TSRC Corporation

Headquarters: Kaohsiung, Taiwan

TSRC Corporation specializes in synthetic rubbers and elastomers, including Maleic Anhydride Grafted SEBS. The company serves automotive, packaging, electronics, and industrial sectors, providing high-performance materials with consistent quality. TSRC emphasizes research and development, developing advanced elastomeric solutions for thermal stability, chemical resistance, and mechanical performance. Its global operations and technical support ensure reliable supply and customer-focused solutions. Sustainability is integrated into its production processes, aligning with environmental standards. TSRC’s innovation-driven approach enables it to address emerging industry needs, positioning the company as a key supplier in high-performance elastomers and functional polymer applications worldwide.

3. Asahi Kasei Corporation

Headquarters: Tokyo, Japan

Asahi Kasei Corporation is a diversified chemical company providing innovative materials, including Maleic Anhydride Grafted SEBS for automotive, electronics, and consumer applications. The company focuses on high-performance polymers, enhancing flexibility, durability, and thermal resistance in elastomer applications. Strong R&D capabilities allow Asahi Kasei to develop sustainable and functional polymer solutions, supporting eco-friendly practices. Its global presence ensures efficient supply and technical support across multiple markets. With a commitment to innovation, quality, and sustainability, Asahi Kasei remains a leading provider of advanced materials, meeting the growing demand for high-performance and customized polymer solutions worldwide.

4. LCY Chemical Corp.

Headquarters: Taipei, Taiwan

LCY Chemical Corp. is a prominent chemical manufacturer specializing in high-quality elastomers, including Maleic Anhydride Grafted SEBS. Serving automotive, construction, electronics, and industrial sectors, LCY provides polymers with superior thermal, mechanical, and chemical properties. The company emphasizes innovation and R&D to develop sustainable, high-performance solutions tailored to market requirements. LCY maintains a strong focus on quality control, global distribution, and technical support, ensuring reliable supply chains. By integrating sustainability into production processes and advancing functional polymer technology, LCY has established itself as a trusted partner in specialty elastomers and high-performance chemical materials.

5. China National Petroleum Corporation (CNPC)

Headquarters: Beijing, China

China National Petroleum Corporation (CNPC) is one of the world’s largest integrated oil and gas enterprises, also producing specialty chemicals such as Maleic Anhydride Grafted SEBS. CNPC serves automotive, construction, electronics, and industrial sectors, providing high-performance polymers and elastomers. The company invests heavily in research, focusing on product innovation, sustainability, and functional performance improvements. CNPC’s global operations and extensive distribution network support large-scale industrial applications. Committed to environmental responsibility and technological advancement, CNPC ensures efficient production, quality assurance, and supply reliability, positioning itself as a key player in the high-performance polymer and chemical materials market.

Are you ready to discover more about the Maleic Anhydride Grafted SEBS market?

The report provides an in-depth analysis of the leading companies operating in the global Maleic Anhydride Grafted SEBS market. It includes a comparative assessment based on their product portfolios, business overviews, geographical footprint, strategic initiatives, market segment share, and SWOT analysis. Each company is profiled using a standardized format that includes:

Company Profiles

- Kraton Corporation.

- Business Overview

- Company Snapshot

- Products Overview

- Company Market Share Analysis

- Company Coverage Portfolio

- Financial Analysis

- Recent Developments

- Merger and Acquisitions

- SWOT Analysis.

- TSRC Corporation

- Asahi Kasei Corporation

- LCY Chemical Corp.

- China National Petroleum Corporation

- Mitsubishi Chemical Corporation

- DIC Corporation

- Dow Inc.

- Wanhua Chemical Group Co., Ltd.

- LG Chem Ltd.

Conclusion

The global Maleic Anhydride Grafted SEBS market is poised for significant growth, driven by rising demand across automotive, electronics, construction, and packaging industries. Superior properties such as enhanced adhesion, flexibility, and compatibility with polar polymers are expanding its applications in adhesives, coatings, and impact modification. Technological advancements, sustainability initiatives, and digital integration in production are further supporting market adoption. Strong growth in emerging economies and high-performance industrial sectors highlights the material’s strategic importance. With leading companies innovating and expanding globally, Maleic Anhydride Grafted SEBS is set to remain a critical solution in the evolving polymer and elastomer landscape.

About the Spherical Insights & Consulting

Spherical Insights & Consulting is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

Which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

CONTACT US:

For More Information on Your Target Market, Please Contact Us Below:

Phone: +1 303 800 4326 (the U.S.)

Phone: +91 90289 24100 (APAC)

Email: inquiry@sphericalinsights.com, sales@sphericalinsights.com

Contact Us: https://www.sphericalinsights.com/contact-us

Need help to buy this report?